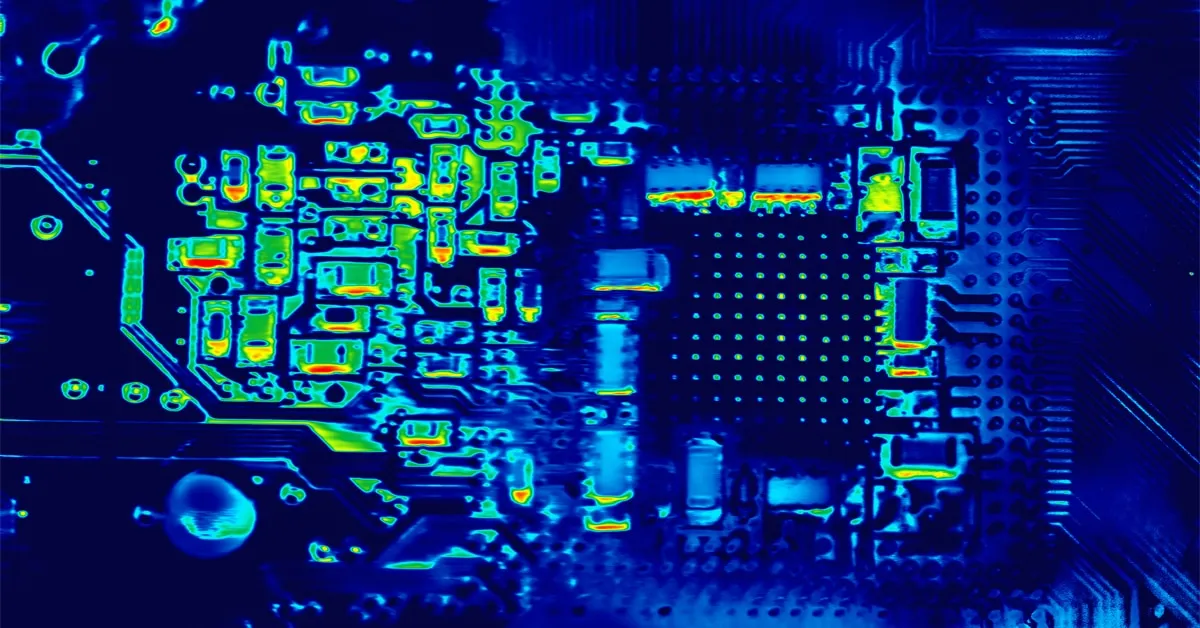

Heat is one of the most critical yet underestimated factors in high-performance industrial systems. In applications such as linear motors, motion control, power electronics, and automation, unmanaged heat can gradually erode efficiency, accuracy, and system reliability. Thermal management provides the framework for controlling temperature, stabilizing performance, and protecting critical components under demanding operating conditions. This article explains what thermal management is, the core challenges engineers encounter, and the practical solutions used to ensure long-term stability and precision in industrial applications.

What Is Thermal Management?

Thermal management refers to the engineering process of controlling, dissipating, and regulating heat within a system to keep all components operating within safe and optimal temperature limits. In industrial and electromechanical systems, heat is an unavoidable byproduct of electrical losses, mechanical motion, and high-duty-cycle operation. Without effective thermal management, excessive heat can quickly compromise performance, accuracy, and long-term reliability.

At its core, thermal management aims to maintain thermal balance, ensuring that the heat generated by a system is efficiently transferred away from critical components before it accumulates. This involves managing heat conduction, convection, and sometimes radiation through carefully designed materials, structures, and cooling mechanisms. The objective is not simply to “remove heat,” but to control temperature distribution in a predictable and stable way.

In motion control and linear motor systems, thermal management plays an even more critical role. Temperature variations can affect magnetic properties, electrical resistance, and mechanical tolerances, leading to changes in force output, positioning accuracy, and efficiency. Over time, uncontrolled heat can accelerate material fatigue, degrade insulation, and shorten the service life of the system.

Effective thermal management integrates mechanical design, electrical engineering, and system-level control strategies. It ensures consistent performance under varying loads, supports continuous operation, and protects high-value components from thermal stress. As industrial systems become more compact and power-dense, thermal management is no longer an optional consideration, it is a fundamental requirement for reliable and high-precision operation.

Why Is Thermal Management Critical in Industrial Applications?

Thermal management is critical in industrial applications because temperature directly influences system performance, reliability, and operational safety. Industrial equipment is often required to operate at high power levels, under continuous loads, and in demanding environments where heat generation is unavoidable. Without effective temperature control, even well-designed systems can experience rapid performance degradation and premature failure.

One of the most significant impacts of poor thermal management is the loss of performance stability. As temperature rises, electrical resistance increases, magnetic efficiency can decline, and mechanical components may expand beyond their intended tolerances. In precision systems such as linear motors and motion control platforms, these thermal effects can result in reduced force output, positioning errors, and inconsistent repeatability.

Reliability and lifespan are also closely tied to thermal conditions. Prolonged exposure to elevated temperatures accelerates material aging, weakens insulation, and increases the likelihood of component fatigue. Bearings, windings, magnets, and electronic control elements are particularly sensitive to heat, making thermal stress a leading cause of unplanned downtime in industrial systems.

Thermal management is equally important for maintaining safety and energy efficiency. Excessive heat increases the risk of system shutdowns, thermal runaway, or even permanent damage to critical components.

At the same time, inefficient heat control can lead to higher energy consumption, as systems work harder to compensate for thermal losses. By managing heat effectively, industrial applications can achieve stable operation, improved efficiency, and long-term reliability, even under continuous and high-performance operating conditions.

Common Sources of Heat in Industrial Systems

Heat in industrial systems is generated from multiple sources that often interact and amplify each other under real operating conditions. Identifying these heat sources is the first step toward designing an effective and reliable thermal management strategy.

- Electrical losses in conductors and windings: Electrical current flowing through cables, windings, and power components inevitably generates heat due to electrical resistance. In motors, this includes copper losses in the windings, which increase rapidly as current and load rise.

- Magnetic losses in cores and electromagnetic components: Alternating magnetic fields in motors, transformers, and inductive components produce hysteresis and eddy current losses. These losses convert electromagnetic energy into heat, particularly in high-speed or high-frequency applications.

- Mechanical friction in moving components: Bearings, guides, seals, and sliding surfaces generate heat through friction. In precision motion and linear motor systems, even minimal friction can lead to localized heat buildup that affects accuracy and repeatability.

- Power electronics and drive systems: Inverters, controllers, and switching devices generate heat during power conversion and switching operations. High switching frequencies and compact drive designs can significantly increase thermal density in control cabinets.

- High load, speed, and duty-cycle operation: Applications involving high acceleration, continuous motion, or heavy loads produce sustained heat over long periods. Continuous-duty operation leaves little time for natural cooling, making heat accumulation unavoidable.

- Environmental and enclosure-related factors: Elevated ambient temperatures, restricted airflow, sealed enclosures, and poor ventilation limit heat dissipation. These external conditions often intensify internal heat generation, especially in compact industrial systems.

Effectively managing heat requires a clear understanding of where it originates and how it propagates through the system. By identifying these common heat sources early in the design process, engineers can select appropriate cooling methods, improve system stability, and ensure consistent performance in demanding industrial applications.

Key Thermal Management Challenges

As industrial systems continue to evolve toward higher performance and greater compactness, managing heat becomes increasingly complex. Thermal challenges are no longer isolated issues but system-level constraints that directly influence reliability, precision, and efficiency.

- Increasing power density in compact designs: Modern industrial equipment is expected to deliver higher output within smaller footprints. This concentration of power generates more heat in limited spaces, making it difficult to dissipate thermal energy effectively without advanced cooling solutions.

- Limited space for heat dissipation and airflow: Compact machine layouts, integrated components, and sealed enclosures restrict natural convection and airflow. These constraints reduce the effectiveness of passive cooling and often require carefully engineered thermal paths.

- Thermal effects on precision and dimensional stability: Temperature variations cause thermal expansion in mechanical structures and changes in electrical and magnetic properties. In high-precision systems such as linear motors, even small temperature gradients can lead to positioning errors, reduced repeatability, and performance drift.

- Continuous operation and high-duty-cycle demands: Many industrial applications operate continuously or under sustained loads with minimal downtime. Continuous heat generation leaves little opportunity for cooling, increasing thermal stress on components and accelerating wear.

- Harsh and variable operating environments: Industrial systems are often exposed to high ambient temperatures, dust, vibration, and limited ventilation. These environmental factors complicate thermal management and can significantly reduce cooling efficiency if not properly addressed.

- Balancing thermal performance with energy efficiency: While active cooling improves heat dissipation, it also consumes additional energy. Designing thermal solutions that maintain safe operating temperatures without increasing energy consumption is a critical challenge for modern industrial systems.

Effectively addressing these challenges requires a holistic approach that integrates thermal considerations into mechanical, electrical, and system-level design from the earliest stages. By understanding and anticipating thermal constraints, engineers can develop solutions that support long-term reliability, precision, and high-performance operation in demanding industrial environments.

Thermal Management Solutions and Techniques

Effective thermal management relies on a combination of design strategies, materials, and control methods tailored to the operating conditions of each industrial system. Rather than applying a single cooling method, engineers often integrate multiple techniques to achieve stable and efficient temperature control.

1. Passive Cooling Solutions

Passive cooling focuses on dissipating heat without external power, making it a reliable and energy-efficient foundation for many industrial systems.

Heat sinks, thermal spreaders, and conductive paths are designed to transfer heat away from critical components and distribute it across a larger surface area. Material selection plays a crucial role, with aluminum and copper commonly used for their high thermal conductivity. Structural design, such as increasing surface area or optimizing contact interfaces, further enhances heat dissipation.

While passive cooling alone may not be sufficient for high-power or continuous-duty applications, it provides a stable baseline that reduces overall thermal load and supports long-term system reliability.

2. Active Cooling Systems

Active cooling introduces forced heat removal using external energy sources and is essential for applications with high power density or sustained heat generation.

Common active cooling techniques include forced air cooling with fans and liquid cooling systems that circulate coolant through dedicated channels. Liquid cooling, in particular, offers superior thermal performance by efficiently transporting heat away from localized hotspots. In high-precision systems, carefully controlled airflow or fluid flow helps maintain consistent operating temperatures.

Although active cooling increases system complexity and energy consumption, it enables industrial systems to operate safely and efficiently under demanding conditions where passive methods alone are insufficient.

3. Thermal Insulation and Heat Isolation

In many applications, effective thermal management is not only about removing heat but also about controlling where heat flows.

Thermal insulation materials and heat barriers are used to protect temperature-sensitive components from nearby heat sources. By isolating critical elements such as sensors, electronics, or precision mechanical structures, engineers can prevent unwanted thermal interference and maintain stable performance.

This approach is particularly important in compact systems where components with very different thermal requirements are placed in close proximity.

4. Intelligent Thermal Monitoring and Control

Modern thermal management increasingly relies on real-time monitoring and adaptive control strategies.

Temperature sensors integrated into motors, drives, and mechanical structures provide continuous feedback on operating conditions. This data enables control systems to adjust cooling intensity, regulate power output, or trigger protective measures when temperature thresholds are reached.

Intelligent thermal control improves system stability, prevents overheating, and allows industrial equipment to operate closer to its optimal performance limits without compromising safety or reliability.

5. Integrated Thermal Design at the System Level

The most effective thermal management solutions are achieved when thermal considerations are embedded into the system design from the outset.

This includes early-stage thermal analysis, simulation, and close coordination between mechanical, electrical, and control engineering teams. Optimizing component placement, airflow paths, and cooling integration ensures that heat is managed efficiently throughout the entire system rather than treated as an afterthought.

A system-level approach reduces design trade-offs, minimizes retrofit costs, and delivers consistent thermal performance under real-world operating conditions.

Thermal management solutions and techniques must be selected based on application requirements, operating environment, and performance goals. By combining passive and active cooling, controlling heat flow, leveraging intelligent monitoring, and integrating thermal design at the system level, industrial systems can achieve stable, reliable, and high-precision operation. As performance demands continue to rise, a well-engineered thermal management strategy becomes a key enabler of long-term efficiency and system reliability.

Conclusion

Thermal management is no longer a supporting consideration in industrial system design, it is a decisive factor that shapes performance, precision, and long-term reliability. As power density increases and systems become more compact, the ability to control heat effectively determines whether equipment can operate consistently under demanding conditions or suffer from gradual degradation and failure.

By understanding the sources of heat, recognizing key thermal challenges, and applying the right combination of passive and active cooling techniques, engineers can significantly enhance system stability and efficiency. When thermal management is integrated early at the system level, it not only protects critical components but also unlocks higher performance, improved accuracy, and extended service life.