Imagine being able to “see” a magnetic field without ever touching it to detect movement, position, or speed with nothing more than a whisper of physics and a dash of engineering magic. That’s the world of the Hall Effect sensor. From keeping electric motors in perfect sync to helping robots move with surgical precision, this tiny device plays an outsized role in modern technology. In the realm of ITG’s linear motion systems, it’s not just a sensor, it’s the silent conductor orchestrating accuracy and reliability.

What Is the Hall Effect Sensor?

The Hall Effect is a classic phenomenon in electromagnetism, first observed in 1879 by American physicist Edwin Hall during his doctoral research at Johns Hopkins University.

While studying how electric currents behave in thin gold leaf conductors, Hall noticed something unexpected: when a magnetic field was applied at right angles to the flow of current, a small but measurable voltage appeared across the conductor, perpendicular to both the current and the magnetic field. This voltage became known as the Hall voltage, and the phenomenon itself as the Hall Effect.

At the heart of the Hall Effect is the Lorentz force, the force that a magnetic field exerts on moving electric charges. When electrons or “holes” (positive charge carriers in semiconductors) travel through a material under the influence of a magnetic field, they are deflected sideways. This sideways motion causes one side of the material to accumulate more negative charge and the opposite side to accumulate more positive charge. The resulting charge imbalance generates a transverse voltage that can be measured with sensitive electronics.

From a physics standpoint, the Hall Effect is significant because it not only confirms the presence of moving charges in a conductor, but also reveals their polarity (negative or positive) and density. From an engineering standpoint, it provides a reliable, non-contact way to detect and quantify magnetic fields.

This discovery eventually led to the development of the Hall Effect sensor, a device that harnesses this principle to measure magnetic field strength, position, speed, and even electric current.

Today, Hall Effect technology is found in a wide range of applications from automotive anti-lock braking systems (ABS) to brushless DC motors, and from robotics to the high-precision linear motor systems used by ITG.

How Does a Hall Effect Sensor Work?

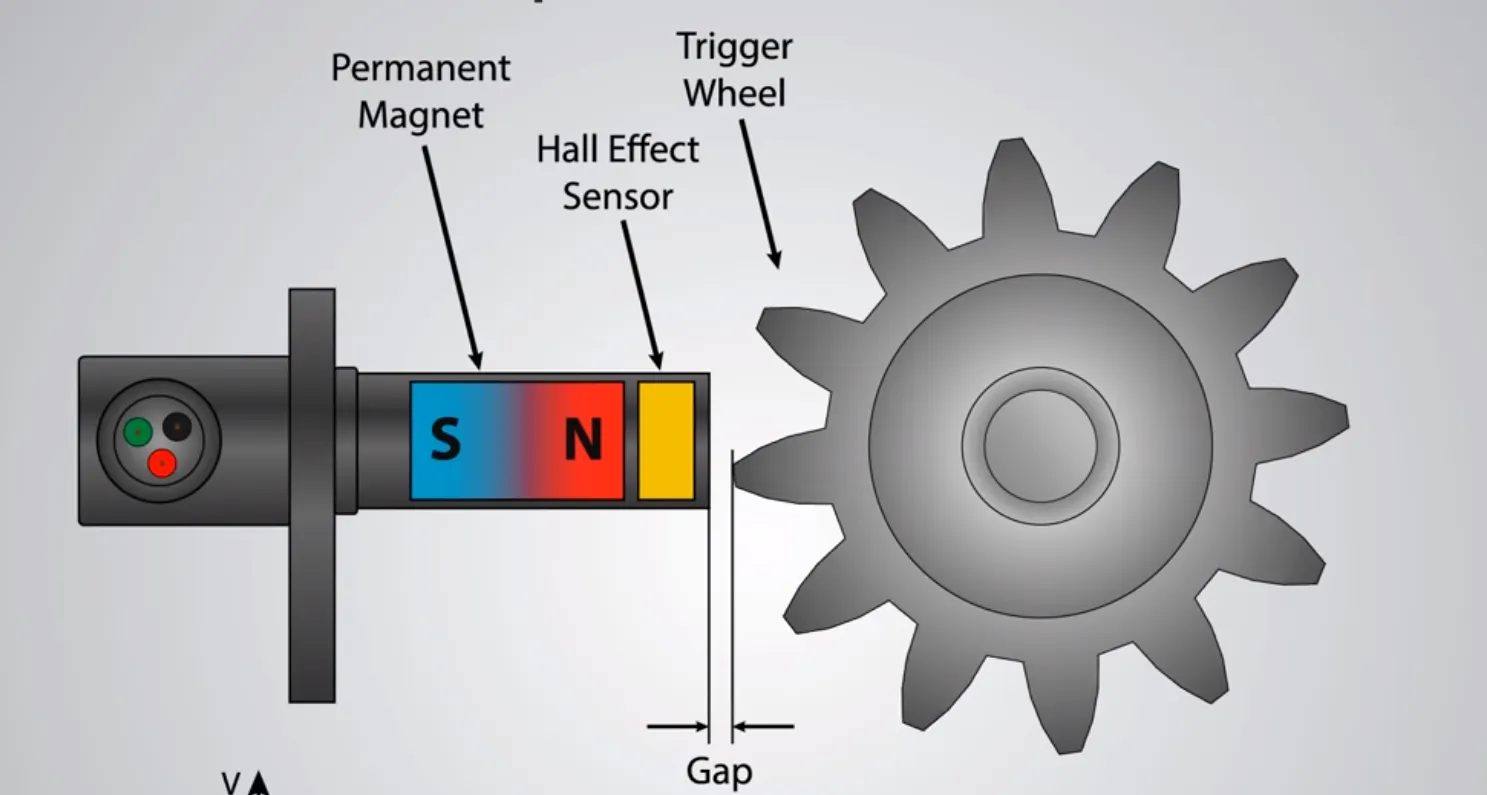

A Hall Effect sensor is an electronic device that uses the Hall Effect principle to detect the presence and characteristics of a magnetic field, then convert that information into an electrical signal. Its operation can be broken down into three main stages:

1. Magnetic Field Detection

- At the core of the sensor is a Hall element, a thin piece of conductive or semiconductive material.

- When current flows through this element, and a magnetic field is applied perpendicular to that current, the Hall Effect generates a Hall voltage across the material.

- The magnitude and polarity of this voltage depend on the strength and orientation of the magnetic field.

2. Signal Conditioning

- The raw Hall voltage is extremely small (often in the microvolt range).

- Inside the sensor package, amplifier circuits boost this signal to a usable level.

- Additional signal processing circuits may filter noise, stabilize the output, and adjust sensitivity.

3. Output Generation

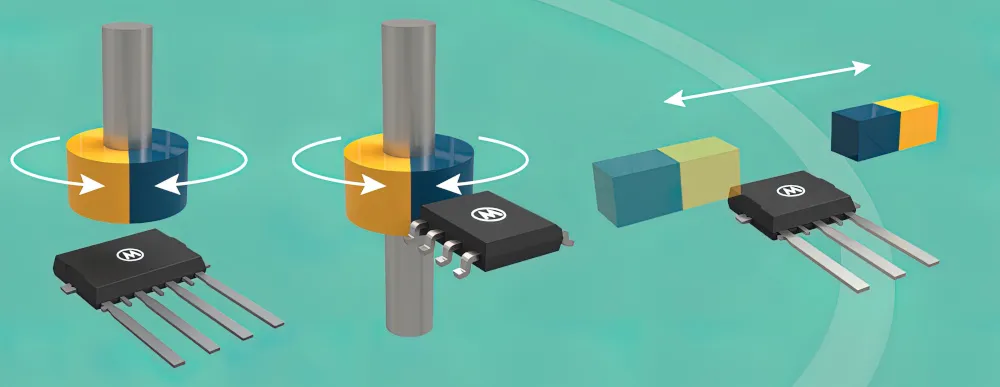

Hall Effect sensors can be designed to produce two main types of output:

- Analog output – A continuous voltage proportional to the magnetic field strength, used in applications such as position sensing or current measurement.

- Digital output – A binary ON/OFF signal triggered when the magnetic field exceeds a certain threshold, commonly used in proximity detection or rotational speed sensing.

By integrating these stages into a compact, sealed package, Hall Effect sensors can deliver fast, accurate, and durable magnetic field measurements. In ITG’s linear motor systems, this translates to precise position feedback and smoother motion control, critical for high-performance automation.

Applications of Hall Effect Sensors

Thanks to their non-contact operation, durability, and precision, Hall Effect sensors are used across a wide range of industries and technologies. Their versatility makes them essential in any application where magnetic field detection, position sensing, or speed measurement is required.

1. Automotive Industry

- Wheel speed detection – Core component in ABS (Anti-lock Braking Systems) to monitor and control wheel rotation.

- Throttle position sensing – Provides precise feedback to engine control units for fuel optimization.

- Gear shift and pedal position monitoring – Enhances driving comfort and safety.

2. Industrial Automation

- Linear and rotary position sensing – Monitors actuator or motor position without mechanical contact.

- Speed control in motors – Used in brushless DC motors to detect rotor position and ensure efficient commutation.

- Proximity detection – Detects the presence of mechanical parts without physical contact, reducing wear.

3. Consumer Electronics

- Smartphone lid/flip detection – Found in foldable devices and laptops to trigger screen on/off.

- Gaming controllers – Enables drift-free joystick movement by replacing traditional potentiometers.

- Home appliances – Used in washing machines, fans, and printers for position or speed sensing.

4. Renewable Energy & Power Systems

- Wind turbine monitoring – Tracks rotor speed and blade position for optimized power generation.

- Electric vehicle charging systems – Detects connector position and ensures safe operation.

- Current sensing – Measures electrical currents in solar inverters and battery management systems.

5. Robotics & Precision Motion Control

- Joint and arm position feedback – Improves accuracy in robotic movements.

- Automated guided vehicles (AGVs) – Detects wheel rotation and positioning for navigation.

- Linear motor feedback – In ITG’s systems, Hall sensors are integrated into Hall Modules to deliver precise, real-time position data for smooth, high-speed motion.

Advantages & Limitations of Hall Effect sensors

Hall Effect sensors have earned their place in modern engineering because they solve problems that other sensing methods cannot. Their design, based on a simple yet powerful principle of physics, gives them capabilities that make them indispensable in applications where precision, reliability, and endurance are critical. But like any technology, they have certain constraints that must be considered during system design.

Advantages – The Strengths That Set Hall Sensors Apart

One of the biggest strengths of Hall Effect sensors is their non-contact operation. Unlike mechanical switches or encoders that rely on physical contact, a Hall sensor “reads” the magnetic field from a distance. This means there is no friction, no wear on the sensing element, and no gradual loss of accuracy over time. The result? A longer operational life with minimal maintenance.

They are also built for tough environments. Whether embedded inside a car’s wheel hub or operating in the dusty interior of an industrial machine, Hall sensors continue to function reliably. They are immune to the contaminants dust, oil, moisture that can degrade optical or mechanical sensors, making them ideal for heavy-duty and outdoor applications.

In terms of measurement quality, Hall sensors excel at precision and repeatability. They can detect tiny changes in magnetic field strength, translating them into accurate measurements of position, speed, or current. This precision is vital in advanced motion control systems such as those found in robotics, renewable energy, and ITG’s high-performance linear motors where even the slightest error can impact overall performance.

Lastly, they offer design flexibility. Available in both analog and digital versions, Hall sensors can be integrated into systems for continuous, real-time data or simple on/off detection. This versatility makes them suitable for a diverse range of applications, from consumer electronics to aerospace.

Limitations – What Engineers Must Account For

Despite their strengths, Hall Effect sensors are not without challenges. The raw Hall voltage generated by the sensing element is extremely small, often just a few microvolts. This requires signal amplification and filtering, which can introduce complexity and cost to the design.

They are also sensitive to temperature variations. Without proper compensation, extreme heat or cold can cause slight measurement drift, which in high-precision systems could be problematic.

Another consideration is their dependence on a magnetic field. If the target object or environment doesn’t naturally produce one, an additional magnet must be installed, adding to the system’s size and cost.

Finally, when compared to basic mechanical switches or reed sensors, initial costs for Hall sensors can be higher. However, for applications where long-term reliability, accuracy, and durability matter, this cost is usually justified.

Hall Effect Sensor in ITG Hall Modules

In many of ITG’s motor solutions, besides Linear Motor Products (Ironcore Linear Motor or Ironless Linear Motor) or Torque Motor, Hall Modules serve as a compact, integrated way to deliver magnetic position feedback. These modules often incorporate Hall Effect seMotor, a proven, contactless sensing technology that measures changes in magnetic fields to determine position and movement.

Here’s how it works in context: the Hall Module is positioned so it can detect the magnetic field generated by magnets placed along the motor’s travel path or rotor. As the motor moves, the magnetic field changes relative to the sensor’s position. The Hall Effect sensor converts these changes into electrical signals, which the motor controller uses to:

- Identify position – Determine the motor’s exact location along a linear axis or rotational path.

- Monitor motion – Detects variations in speed and direction to maintain smooth, precise control.

- Enable commutation – Provide timing information for electronically commutated motors.

Because this measurement is non-contact, there’s no friction between sensing elements and moving parts. This not only reduces wear, but also ensures the feedback remains accurate over time, even in industrial environments where dust, vibration, or temperature variations are present.

In ITG’s Hall Modules, the Hall Effect sensor is integrated into a housing that can be directly mounted on the motor’s coil unit or assembly. This makes installation straightforward and helps maintain signal stability by keeping the sensing components in a fixed, protected position.

The result is a position feedback system that is:

- Consistent – Reliable signal output across repeated cycles.

- Low-maintenance – Minimal servicing needed thanks to contactless operation.

- Compact – Integrated design that fits neatly into the motor system without adding bulk.

By combining this sensing method with precise mechanical design, ITG’s Hall Modules can provide feedback that supports high-performance motor control without unnecessary complexity.

Conclusion

From its discovery in 1879 to its role in today’s precision motion systems, the Hall Effect has proven to be a simple yet powerful way to detect and measure magnetic fields. In modern engineering, Hall Effect sensors offer accuracy, reliability, and durability that few other sensing methods can match. Whether tracking speed, position, or direction, they quietly enable the seamless control we expect from advanced technologies. And in solutions like ITG’s Hall Modules, this principle is applied in a practical, integrated form turning fundamental physics into real-world performance.