Looking for precise, repeatable motion without the complexity of traditional motors? Permanent magnet stepper motors might be the solution you’ve been searching for. These motors offer an elegant balance of simplicity, accuracy, and control making them ideal for applications where every movement counts. In this article, we’ll break down what a permanent magnet stepper motor is, how it works, and why it continues to be a go-to choice in automation, robotics, and beyond.

What is a Permanent Magnet Stepper Motor?

A Permanent Magnet Stepper Motor (PM stepper motor) is a type of stepper motor that uses a permanent magnet in the rotor and electromagnetic coils in the stator to create rotational motion in discrete steps. Unlike traditional motors that rotate continuously, a PM stepper motor moves in fixed angular increments, allowing for precise control of position without the need for sensors or feedback systems.

The rotor of a PM stepper motor is made of permanent magnet materials, typically magnetized in a north-south pole configuration. When electrical pulses are applied to the stator windings in a specific sequence, a rotating magnetic field is produced, which interacts with the magnetic field of the rotor, causing it to align and “step” to the next position.

Key Characteristics:

- Discrete movement: Each input pulse causes the motor to move one step.

- Open-loop control: No need for encoders or feedback devices.

- Low-speed, high-torque performance: Suitable for applications requiring accurate and stable positioning at low speeds.

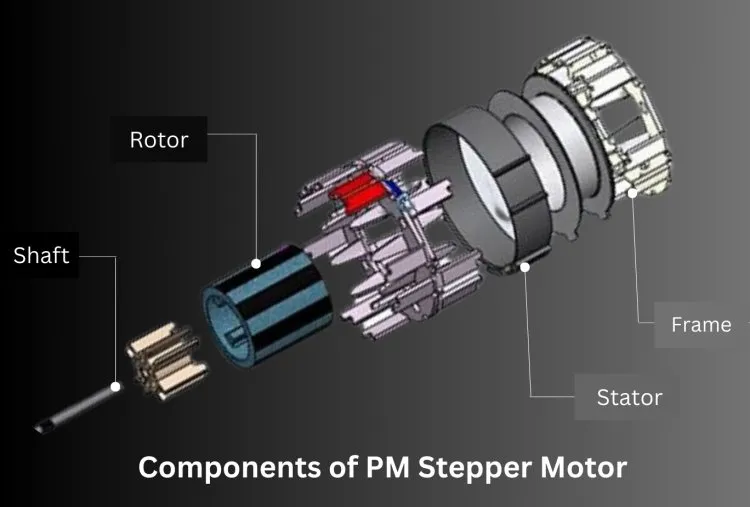

Main Components of a Permanent Magnet Stepper Motor

1. Rotor (Permanent Magnet):

-

- Made from permanent magnetic material (usually ferrite or rare-earth).

- Magnetized in a north-south pole configuration.

- Rotates step-by-step as it aligns with stator magnetic fields.

2. Stator (Electromagnetic Coils):

-

- Contains multiple windings (phases) arranged around the rotor.

- When energized in sequence, they create a rotating magnetic field.

3. Motor Shaft:

-

- Connected to the rotor, it delivers mechanical motion to the external load.

4. Bearings:

-

- Support the rotor shaft and allow smooth rotation with minimal friction.

5. Housing / Frame:

-

- Encases and protects internal components; provides structural support.

6. Lead Wires / Terminals:

-

- Provide electrical connection between the stator windings and driver/controller.

How It Differs from Other Stepper Motors:

- Compared to Variable Reluctance Stepper Motors: PM stepper motors have a magnetized rotor, while VR motors use a soft iron rotor without permanent magnetism.

- Compared to Hybrid Stepper Motors: Hybrid motors combine features of PM and VR motors and offer higher precision and torque but at a higher cost.

Thanks to their simplicity and reliability, permanent magnet stepper motors are commonly used in applications such as medical devices, small robotics, and basic motion control systems.

How Does a Permanent Magnet Stepper Motor Work?

A Permanent Magnet Stepper Motor works by converting electrical pulses into mechanical rotation through the interaction of magnetic fields. Its operation is based on the principle of electromagnetism and the natural tendency of magnets to align with magnetic fields.

Step-by-Step Working Principle:

1. Electromagnetic Coil Activation: The stator contains multiple electromagnetic windings arranged in phases. When current flows through one of the windings, it creates a magnetic field that attracts the permanent magnet rotor.

2. Stepping Action: As each winding is energized in a specific sequence (also known as a stepping sequence), the rotor moves in discrete steps to align itself with the changing magnetic field. Each pulse advances the rotor by a fixed angle, known as the step angle.

3. Continued Rotation: By rapidly switching current between the stator coils in a programmed order, continuous rotational motion is achieved. The motor’s rotation speed and direction can be precisely controlled by adjusting the pulse frequency and sequence.

Types of Step Control Modes

- Full Step: The rotor moves by one full step per pulse. Offers maximum torque but less smoothness.

- Half Step: The rotor alternates between full and intermediate positions, offering improved resolution and smoother motion.

- Microstepping: The current in the windings is controlled in finer increments to divide each step into smaller parts, resulting in very smooth and precise motion—ideal for high-precision applications.

No Feedback Needed

One of the defining features of stepper motors, including permanent magnet types, is their ability to operate in open-loop mode meaning they don’t require feedback devices like encoders to track position. This simplifies the control system while still maintaining accurate motion.

Advantages of Permanent Magnet Stepper Motors

Permanent magnet stepper motors offer a range of benefits that make them a practical and cost-effective choice for various motion control applications. Their simplicity, precision, and reliability give them a unique edge in systems where controlled, incremental movement is essential.

1. Precise Positioning Without Feedback

One of the most appealing advantages is their ability to move in exact steps. This eliminates the need for complex feedback systems such as encoders or sensors, reducing system complexity and cost while still maintaining accurate control.

2. Simple and Robust Design

PM stepper motors have a straightforward construction typically consisting of a permanent magnet rotor and stator windings. This simplicity translates to high durability, fewer failure points, and easier maintenance.

3. Excellent Low-Speed Torque

These motors are well-suited for low-speed applications where high starting torque is required. Unlike many traditional motors, PM stepper motors don’t need gearing to achieve powerful low-speed rotation.

4. Cost-Effective Motion Control

Because they operate in open-loop mode and don’t require expensive control systems, PM stepper motors are a budget-friendly option for applications that demand reliable and repeatable motion.

5. Holding Torque When Stationary

Even when the motor is not rotating, it can maintain its position under load as long as power is applied. This holding torque makes it ideal for applications where maintaining a fixed position is crucial, such as in 3D printers and medical equipment.

6. Easy to Control and Integrate

PM stepper motors are compatible with a wide range of simple driver circuits and microcontrollers. This ease of control makes them ideal for prototyping, educational use, and compact embedded systems.

Applications of Permanent Magnet Stepper Motors

Permanent magnet stepper motors are widely used in applications where precise, controlled, and repeatable motion is needed but without the complexity or cost of servo systems. Their unique combination of simplicity, accuracy, and torque at low speeds makes them ideal for a variety of industries.

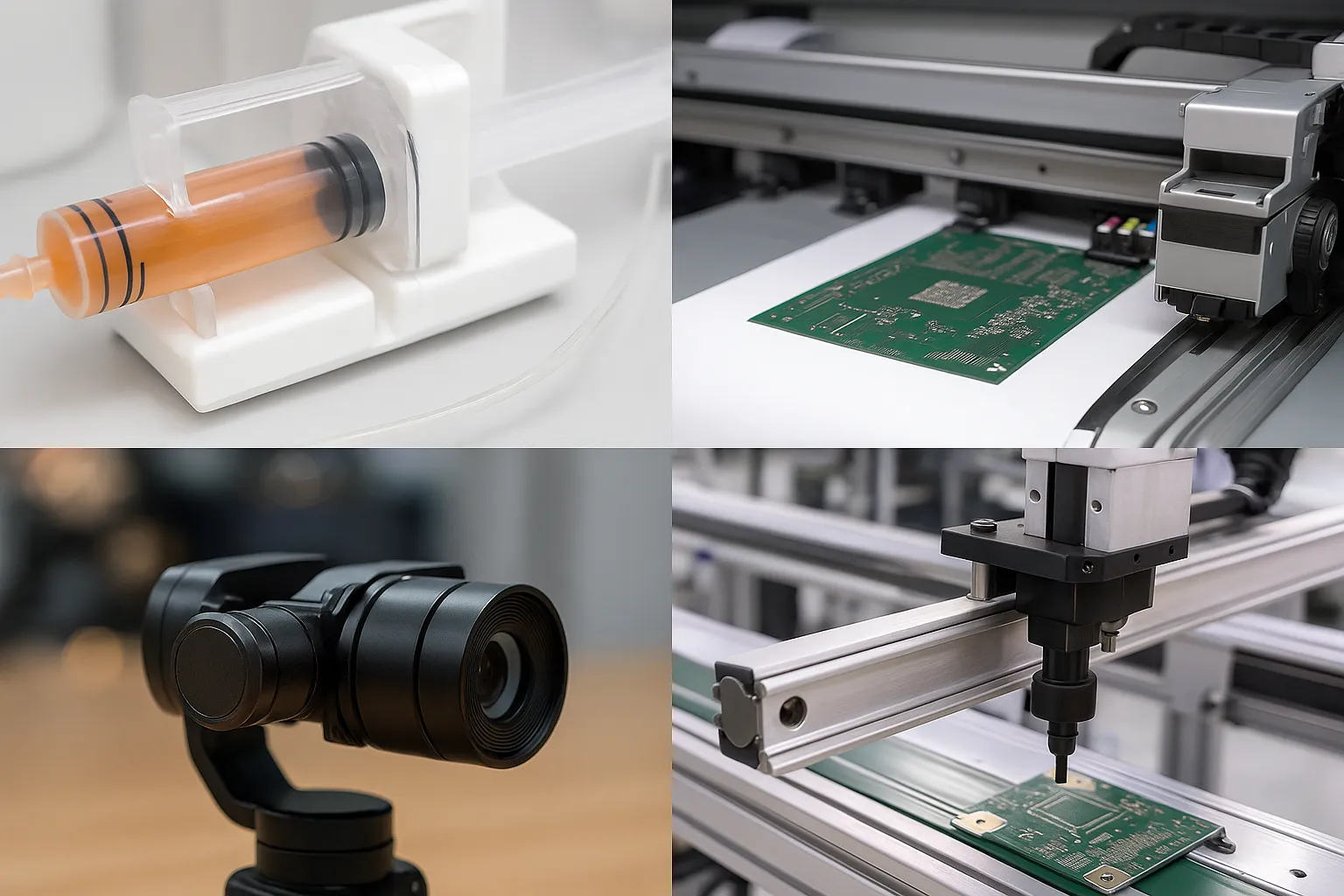

1. Medical and Laboratory Devices

PM stepper motors are a perfect fit for the medical and laboratory field, where precision, cleanliness, and reliability are non-negotiable.

- Examples of Use:

- Syringe pumps for fluid dosing

- Automated blood analyzers

- Sample positioning systems

- DNA sequencers

In these environments, the smooth, low-speed control and static holding torque of PM stepper motors allow for micro-level movements essential when dealing with small volumes or fragile biological materials.

2. Printers, Scanners, and Office Equipment

From paper feeding to printhead positioning, PM stepper motors drive the core mechanisms in many office devices.

- Examples of Use:

- Dot-matrix and inkjet printers

- Document scanners

- Fax machines and copiers

- Card dispensers or sorters

Their open-loop precision means these motors can execute repeatable movements without needing encoders, keeping design and production costs low.

3. Consumer Electronics and Small Robotics

In compact consumer devices or entry-level robotics, PM stepper motors offer the perfect balance between control and affordability.

- Examples of Use:

- Camera lens and gimbal control

- Automated curtain systems

- Smart locks and dispensers

- Entry-level robot arms and sliders

PM stepper motors are often chosen over DC motors in these applications because they provide precise positioning without requiring complicated control loops.

4. Industrial Automation (Light-Duty Tasks)

Though not built for high-speed or heavy-load industrial systems like servo motors, PM stepper motors are excellent for light-duty automation where consistent motion is more important than high dynamics.

- Examples of Use:

- Conveyor belt indexing

- Label applicators

- Inspection camera alignment

- Pick-and-place mechanisms for small parts

In these roles, PM stepper motors provide predictable, failure-resistant motion that helps keep operations running smoothly without requiring constant calibration or maintenance.

Permanent magnet stepper motors are not universal solutions but in applications where controlled, low-speed, and repeatable motion is key, they shine. From life-saving medical equipment to everyday printers and smart home gadgets, these motors quietly power precision behind the scenes.

Conclusion

Permanent magnet stepper motors may be simple in design, but their reliability, precision, and control make them powerful tools in modern motion systems. From medical devices to robotics and light-duty automation, they excel in tasks where accuracy matters more than speed.

Understanding how they work and when to use them gives engineers and designers more flexibility to build smarter, more efficient systems. And when your application calls for more advanced motion solutions, such as Ironcore / Ironless linear motors for high-speed travel, hall modules for precise sensing, or torque motors for direct-drive power, it helps to have the right partner.

At ITG, we don’t just supply motors, we help you move smarter.