In today’s high-precision manufacturing and automation environment, motion systems are no longer just about movement, they are about speed, accuracy, and long-term reliability. As industries push toward higher productivity and smarter factories, traditional mechanical transmission systems are increasingly being replaced by direct-drive technologies. Among them, the magnetic linear motor has emerged as a powerful solution for applications that demand precise, smooth, and highly dynamic linear motion.

Unlike conventional rotary motors that rely on screws, belts, or gears to convert rotation into linear movement, a magnetic linear motor generates direct linear force through electromagnetic interaction. This design not only eliminates mechanical wear but also enables superior positioning accuracy, faster response, and greater system efficiency. In this article, we will explore what a magnetic linear motor is, how it is structured, and the key components that make it an essential technology in modern motion control systems.

What Is a Magnetic Linear Motor?

A magnetic linear motor is an electromechanical device that produces a direct linear motor through electromagnetic interaction, without the need for mechanical transmission components such as gears, belts, or ball screws. Instead of converting rotational motion into linear movement, the motor generates force in a straight line, allowing the moving element to travel directly along a linear path with high precision and efficiency.

At its core, a magnetic linear motor operates based on the same fundamental principles as conventional electric motors, but with one key difference: the motor is “unrolled.” In a traditional rotary motor, electromagnetic forces create torque around a shaft. In a magnetic linear motor, these forces are rearranged to produce linear thrust, enabling controlled movement along a predefined axis.

From a structural perspective, a magnetic linear motor typically consists of two main parts: a primary component, which contains the electrical windings and carries current, and a secondary component, which is equipped with permanent magnets or conductive materials. When electrical current flows through the windings, it interacts with the magnetic field generated by the magnets, producing a controlled electromagnetic force that drives linear motion.

One of the defining characteristics of magnetic linear motors is their direct-drive nature. Because there is no physical contact between moving mechanical transmission elements, the system experiences minimal friction and virtually no backlash. This results in smoother motion, higher positioning accuracy, and significantly reduced maintenance requirements compared to traditional linear motion systems.

Thanks to these advantages, magnetic linear motors are widely used in applications where high speed, rapid acceleration, and micron-level precision are critical. Common examples include semiconductor manufacturing equipment, high-speed automation lines, precision robotics, and advanced inspection systems. As modern industries continue to demand greater performance and reliability, magnetic linear motors have become a cornerstone technology in advanced motion control solutions.

Basic Working Principle of a Magnetic Linear Motor

The operating principle of a magnetic linear motor is based on the interaction between electric current and magnetic fields, which generates a controlled linear force. Unlike mechanical linear systems that rely on motion conversion, a magnetic linear motor produces thrust directly along a straight axis, enabling highly efficient and precise movement.

At the heart of the system is the electromagnetic force, commonly described by the Lorentz force principle. When an electric current flows through the windings of the motor’s primary component, it creates a magnetic field. This field interacts with the magnetic field generated by the permanent magnets located on the secondary component. The interaction between these two magnetic fields produces a force that acts in a linear direction, pushing or pulling the mover along the motor’s track.

The direction and magnitude of this linear force are precisely controlled by adjusting the current amplitude, phase, and sequence supplied to the motor windings. By synchronizing the current with the magnetic field pattern of the permanent magnets, the motor can generate smooth, continuous motion with accurate control over position, velocity, and acceleration. This principle is similar to that of a rotary synchronous motor, but instead of producing rotational torque, the system generates linear thrust.

In practical applications, magnetic linear motors are operated within a closed-loop control system. High-resolution position feedback devices, such as linear encoders, continuously monitor the mover’s position and send real-time data to the motion controller. The controller then dynamically adjusts the drive signals to maintain precise motion profiles, ensuring high repeatability and stability even at high speeds or during rapid acceleration.

Because the working principle of a magnetic linear motor eliminates mechanical contact between transmission components, the system experiences minimal friction and zero backlash. This not only improves motion smoothness and accuracy but also enhances efficiency and reduces wear-related maintenance. As a result, magnetic linear motors are particularly well suited for high-performance motion control applications that demand speed, precision, and long-term reliability.

Structure of a Magnetic Linear Motor

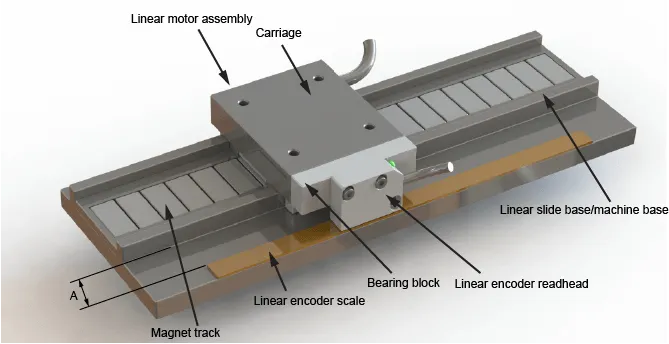

The structure of a magnetic linear motor is designed to deliver direct, high-precision linear motion by optimizing the interaction between electromagnetic components. While specific designs may vary depending on application requirements, most magnetic linear motors share a common structural architecture composed of several key elements working in close coordination.

1. Primary Part (Forcer / Mover)

The primary part, often referred to as the forcer or mover, is the active component of the magnetic linear motor. It contains the electrical windings that carry current supplied by the motor drive. When energized, these windings generate a controlled magnetic field that interacts with the magnetic field of the secondary part to produce linear thrust.

The primary part is typically mounted on the moving axis and is responsible for dynamic motion generation. Because electrical current flows through the windings, heat is inevitably produced during operation. As a result, thermal management such as natural convection, forced air cooling, or liquid cooling is a critical design consideration to ensure stable performance and long-term reliability.

2. Secondary Part (Magnet Track / Stator)

The secondary part, commonly called the magnet track or stator, consists of a series of permanent magnets arranged in a precise pattern along the motion path. These magnets create a stable and continuous magnetic field that serves as the foundation for thrust generation.

Depending on the motor design, the magnet track may include a steel back iron to enhance magnetic flux density or may be configured as an ironless structure to minimize cogging forces. The secondary part is usually fixed to the machine frame and defines the travel length of the magnetic linear motor.

3. Air Gap

The air gap is the small, carefully controlled distance between the primary and secondary parts. Although it may appear simple, the air gap plays a crucial role in motor performance. Its size directly affects force output, efficiency, and positioning accuracy.

Maintaining a consistent air gap requires precise mechanical alignment and high-quality mounting structures. Even minor variations can influence electromagnetic interaction, making air gap control a key factor in high-precision linear motor systems.

4. Mechanical Support and Guidance System

While magnetic linear motors eliminate mechanical transmission components, they still require a mechanical guidance system to constrain motion along the desired axis. Linear guides, bearings, or air bearings are commonly used to support the moving element and maintain stability throughout the stroke.

The quality of the guidance system has a significant impact on overall system accuracy, smoothness, and load-carrying capability. When properly integrated, it complements the magnetic linear motor by enabling precise and repeatable motion under varying load conditions.

Key Components of a Magnetic Linear Motor

A magnetic linear motor is composed of several critical components that work together to deliver precise, high-speed, and reliable linear motion. Each component plays a specific role in generating thrust, controlling movement, and maintaining system stability. Understanding these key elements is essential for selecting and designing linear motor systems for demanding industrial applications.

1. Permanent Magnets

Permanent magnets are a fundamental component of magnetic linear motors, as they create the static magnetic field required for force generation. These magnets are typically mounted on the secondary part of the motor and arranged in a precise sequence to form alternating magnetic poles along the motion path.

High-performance magnetic linear motors commonly use neodymium iron boron (NdFeB) magnets due to their high magnetic energy density. The quality, arrangement, and magnetization pattern of the magnets directly influence thrust force, efficiency, and overall motor performance.

2. Windings and Coils

The windings and coils are located in the primary part of the magnetic linear motor and are responsible for generating a dynamic magnetic field when electrical current is applied. As current flows through the coils, it interacts with the magnetic field produced by the permanent magnets, resulting in linear thrust.

Different winding configurations are used to optimize force output, smoothness, and thermal behavior. Proper coil design is essential to achieve high acceleration and precise motion control while minimizing heat generation and power losses.

3. Position Feedback System

Accurate motion control in a magnetic linear motor relies heavily on a position feedback system. Linear encoders or magnetic sensors continuously monitor the exact position of the mover and provide real-time feedback to the motion controller.

This closed-loop feedback enables extremely high positioning accuracy and repeatability, even at high speeds. In precision applications, high-resolution optical linear encoders are often used to achieve micron or sub-micron level accuracy.

4. Drive and Motion Controller

The drive and motion controller regulate the electrical power supplied to the motor windings and coordinate the motion profile. The drive converts electrical input into precisely controlled current signals, while the controller manages position, velocity, and acceleration based on feedback data.

Advanced controllers allow for smooth trajectory planning, vibration reduction, and synchronization with other axes or systems. This level of control is essential for complex automation and high-performance motion applications.

5. Cooling System

Because magnetic linear motors operate with high current density, thermal management is a critical component of system design. Cooling systems help dissipate heat generated by the windings, ensuring stable performance and preventing overheating.

Depending on the application, cooling may be achieved through natural air convection, forced air cooling, or liquid cooling. Effective cooling extends motor lifespan and maintains consistent force output under continuous or high-load operation.

Types of Magnetic Linear Motors

Magnetic linear motors come in a variety of designs, each optimized for specific performance requirements and application environments. While all types operate on the same electromagnetic principles, their structural differences significantly influence force density, precision, thermal behavior, and cost-effectiveness. The most common types of magnetic linear motors include:

- Iron-core magnetic linear motors, which incorporate a steel core in the primary part to concentrate magnetic flux and generate high thrust force. This design is well suited for applications that require heavy load capacity and strong acceleration, such as industrial automation and machining systems. However, the presence of iron can introduce cogging forces, which must be carefully managed through design and control strategies.

- Ironless (slotless) magnetic linear motors, designed without an iron core to eliminate cogging and achieve exceptionally smooth motion. These motors are ideal for ultra-precision applications where vibration-free movement and consistent force output are critical, including semiconductor manufacturing and high-end inspection equipment. While ironless designs typically offer lower force density, they excel in accuracy and motion quality.

- Tubular magnetic linear motors, which feature a cylindrical structure with magnets arranged around a central shaft. This configuration provides balanced magnetic forces and a compact form factor, making it suitable for space-constrained applications and vertical motion systems. Tubular designs often deliver high efficiency and clean integration into modular machine architectures.

- Flat magnetic linear motors, characterized by a planar magnet track and a flat forcer design. These motors offer flexible stroke lengths and easy scalability, allowing them to be integrated into large or customized motion platforms. Flat linear motors are widely used in long-travel applications such as gantry systems and automated production lines.

- Single-sided and double-sided magnetic linear motors, differentiated by the placement of magnet tracks. Single-sided designs prioritize simplicity and lower cost, while double-sided configurations provide higher force output and improved force symmetry, enhancing stability in demanding applications.

Each type of magnetic linear motor offers distinct advantages and trade-offs. Selecting the right configuration depends on factors such as required force, positioning accuracy, speed, thermal limits, and available installation space. By understanding these differences, engineers and system designers can choose a magnetic linear motor solution that delivers optimal performance for their specific application needs.

Conclusion

Magnetic linear motors represent a fundamental shift in the way linear motion is generated and controlled. By eliminating mechanical transmission components and leveraging electromagnetic force for direct-drive motion, these motors deliver exceptional precision, high dynamic performance, and long-term reliability. From their working principles and structural design to the key components and various motor types, magnetic linear motors offer a versatile and powerful solution for modern motion control challenges.

As industries continue to move toward higher levels of automation, accuracy, and efficiency, magnetic linear motors are becoming an essential technology across manufacturing, robotics, semiconductor, and precision engineering applications. Choosing the right motor configuration and integrating it with an advanced control system, can significantly enhance system performance and future-proof industrial equipment.