Have you ever imagined a motor that doesn’t rotate but moves in a straight line, powering high-speed trains, advanced conveyors, and futuristic rides? That’s exactly what a Linear Induction Motor (LIM) does. Unlike traditional rotary motors, LIM creates linear motion directly without the need for gears or wheels, making it a game-changer in transportation and automation. In this article, we’ll explore what a Linear Induction Motor is, its construction, how it works, and why it’s revolutionizing modern engineering.

What is a Linear Induction Motor?

A Linear Induction Motor (LIM) is an advanced type of induction motor that produces linear motion instead of rotational motion. Unlike traditional rotary motors that spin a shaft, a LIM generates a straight-line force directly, eliminating the need for additional mechanical components like gears or pulleys.

At its core, the working principle of a LIM is the same as a conventional induction motor, it operates on the principle of electromagnetic induction. However, instead of creating a rotating magnetic field, a LIM produces a traveling magnetic field that interacts with a secondary conductor, generating thrust in a straight path.

Types of Linear Induction Motors

Linear Induction Motors (LIMs) are primarily classified based on the position and length of their primary and secondary components. The two most common types are:

1. Short Primary Linear Induction Motor

In this design, the primary winding (similar to the stator) is shorter than the secondary part. The secondary, often made of aluminum or copper sheets on a steel backing, is longer and remains stationary, while the primary moves.

- Advantages:

- Lightweight moving component (primary)

- Ideal for applications like rail transportation and maglev trains, where the long track acts as the secondary.

- Disadvantages:

- Requires a long stationary secondary, increasing infrastructure cost.

2. Short Secondary Linear Induction Motor

Here, the secondary (similar to the rotor) is shorter and moves, while the primary winding is long and remains fixed.

- Advantages:

- Lower installation cost for the secondary

- Common in conveyors, industrial automation systems, and amusement rides.

- Disadvantages:

- The long primary adds complexity and cost in stationary infrastructure.

This unique feature makes LIM highly suitable for applications where direct linear motion is required, such as maglev trains, automated material handling systems, and amusement rides.

Construction of Linear Induction Motor

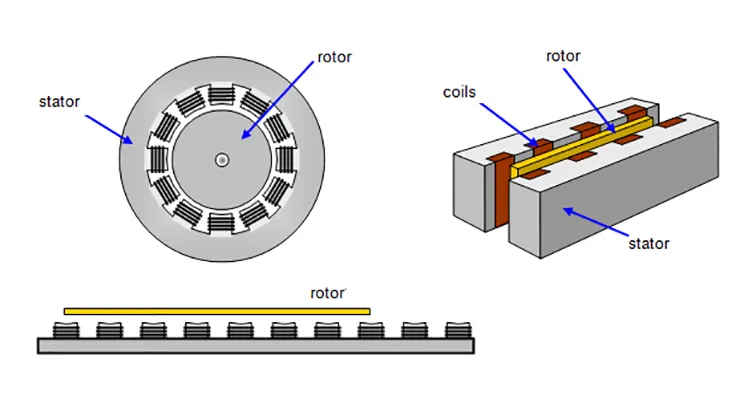

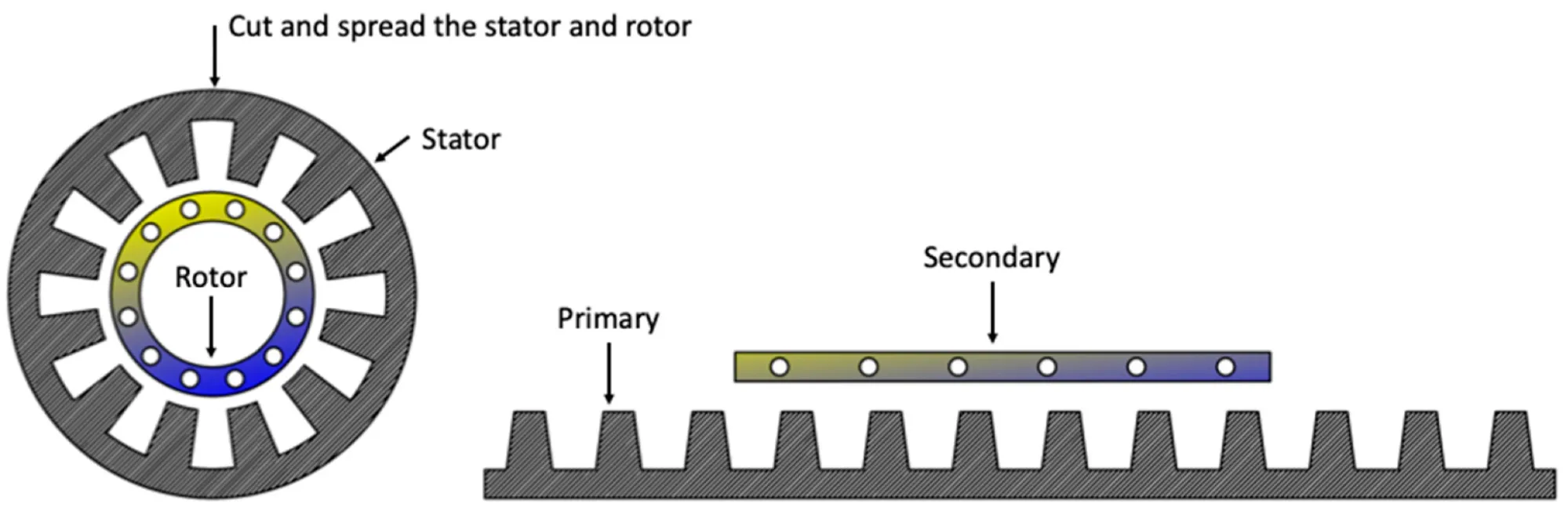

The construction of a Linear Induction Motor (LIM) is quite similar to a conventional rotary induction motor, but instead of being cylindrical, it is “unrolled” into a flat or slightly curved shape to produce linear motion. A LIM consists of two main parts: the primary and the secondary, separated by an air gap.

1. Primary (Stator Equivalent)

- The primary of a LIM is similar to the stator of a rotary motor.

- It consists of laminated steel cores and three-phase windings arranged to create a traveling magnetic field when energized with AC supply.

- This component can be either stationary or moving, depending on the LIM type (short primary or short secondary).

2. Secondary (Rotor Equivalent)

- The secondary acts like the rotor in a traditional motor.

- It is usually made of conductive material such as aluminum or copper sheets mounted on a ferromagnetic backing plate.

- Unlike the primary, the secondary is generally passive, meaning it does not need an electrical connection.

3. Air Gap

- A small air gap separates the primary and secondary.

- Maintaining the correct gap is critical for efficient magnetic flux and force generation.

Physical Layout

- In rotary motors, the magnetic field rotates around a cylindrical stator and rotor.

- In LIM, the same principle is applied in a linear fashion, where the magnetic field travels along the length of the motor to produce straight-line thrust.

Working Principle of Linear Induction Motor

The working principle of a Linear Induction Motor (LIM) is based on Faraday’s law of electromagnetic induction and the concept of a traveling magnetic field. Unlike a rotary induction motor that generates torque to rotate a shaft, a LIM produces linear thrust to move an object in a straight line. Let’s break it down into three key stages:

1. Creation of a Traveling Magnetic Field

When a three-phase AC supply is applied to the primary winding, it generates a rotating magnetic field in a conventional motor. However, in a LIM, the winding is spread out linearly, so the rotating magnetic field becomes a traveling magnetic field that moves along the length of the motor.

- This field travels at a speed known as the synchronous speed and induces current in the secondary conductor.

- The speed of the traveling field can be controlled by adjusting the frequency of the AC supply, making LIMs highly adaptable for different applications.

2. Electromagnetic Induction and Eddy Currents

As the traveling magnetic field passes over the secondary, Faraday’s law comes into play. The changing magnetic flux induces eddy currents in the secondary conductor (aluminum or copper sheet).

- According to Lenz’s law, these currents create their own magnetic field, which opposes the original field.

- This interaction produces a linear force (thrust) on the secondary, pushing it forward in a straight line.

3. Production of Linear Motion

The thrust generated by the interaction of the magnetic fields moves either the primary or secondary, depending on the design of the motor (short primary or short secondary).

- The direction of motion can be reversed by changing the phase sequence of the AC supply, similar to reversing a rotary induction motor.

- The motor does not require gears, pulleys, or additional mechanical components, making it highly efficient for high-speed transport systems and automated machinery.

In short, a Linear Induction Motor converts electrical energy into linear mechanical motion directly, without intermediate rotary movement. This unique feature makes it ideal for modern transportation technologies such as maglev trains, as well as industrial automation systems where precise linear motion is essential.

Advantages and Disadvantages of Linear Induction Motors

Linear Induction Motors (LIMs) offer unique benefits compared to traditional rotary motors, but they also come with certain limitations. Understanding both sides helps in selecting the right motor for specific applications.

Advantages of Linear Induction Motors

Linear Induction Motors offer several distinct benefits that make them ideal for modern applications requiring speed, precision, and reliability:

1. Direct Linear Motion: Produces straight-line movement without additional mechanical parts like gears or pulleys, reducing complexity.

2. High-Speed Capability: Well-suited for maglev trains and high-speed transport systems where rapid motion is essential.

3. Low Maintenance: Fewer moving parts mean less wear and tear, leading to longer service life and lower maintenance costs.

4. Smooth and Quiet Operation: Minimizes vibration and noise, ensuring a silent and stable performance.

5. Easy Speed Control: Speed and direction can be adjusted easily by controlling the frequency and phase of the AC supply.

Disadvantages of Linear Induction Motors

Despite these advantages, LIMs also present certain challenges that need to be considered before implementation:

1. High Initial Cost: Requires expensive infrastructure, especially in transportation systems.

2. Lower Efficiency: Energy losses occur due to large air gaps and end effects, reducing overall efficiency.

3. Limited Force Over Long Distances: The linear thrust decreases as the motor length increases, making scaling difficult.

4. Heating Issues: Significant eddy current losses generate heat, requiring additional cooling measures.

5. Complex Installation: Needs precise alignment and specialized tracks, adding complexity to setup.

In conclusion, Linear Induction Motors deliver outstanding performance in terms of speed, smooth motion, and low maintenance. However, their higher cost and efficiency issues mean they are best suited for applications where these unique benefits outweigh the drawbacks, such as maglev transportation, automated material handling, and theme park rides.

Applications of Linear Induction Motors

Linear Induction Motors (LIMs) have found their place in many advanced technologies thanks to their ability to deliver direct linear motion with speed, precision, and minimal maintenance. Below are the most notable applications where LIM technology truly shines.

High-Speed Transportation (Maglev Trains)

One of the most iconic uses of Linear Induction Motors is in maglev trains. Unlike traditional trains that rely on wheels and tracks, maglev systems use LIMs to create thrust without physical contact, allowing trains to float and move at incredible speeds. For example, the Shanghai Maglev Train operates at speeds up to 431 km/h, demonstrating how LIM technology is revolutionizing high-speed transportation.

Industrial Automation and Material Handling

In factories and warehouses, precision and reliability are critical for moving materials efficiently. LIMs power automated conveyor systems and robotic platforms by providing smooth and accurate linear motion without the need for gears or mechanical linkages. This not only reduces maintenance but also ensures seamless integration into advanced manufacturing lines where downtime is costly.

Amusement and Theme Park Rides

When it comes to delivering thrilling experiences, amusement parks rely on LIMs for high-speed roller coasters and launch rides. These motors allow rides to achieve instant acceleration without mechanical chains or belts, creating an exciting and smooth experience for riders.

Airport Baggage Handling Systems

Airports face the challenge of moving thousands of bags efficiently every day. LIM-based conveyor systems offer a quiet, reliable, and fast solution for baggage handling. Their ability to deliver consistent speed and accuracy ensures smooth airport operations, reducing delays and improving the passenger experience.

Automated Guided Vehicles (AGVs)

In modern logistics and warehouse environments, AGVs play a critical role in moving goods autonomously. Some AGVs use LIMs for propulsion, benefiting from their smooth, precise motion and ability to operate without mechanical drive systems. This makes them ideal for smart warehouses and automated distribution centers.

In summary, Linear Induction Motors have transformed industries ranging from transportation and entertainment to automation and logistics. Their ability to provide high-speed, reliable, and low-maintenance linear motion continues to make them a cornerstone technology for the future.

Conclusion

Linear Induction Motors are more than just an evolution of traditional motors, they’re a gateway to the future of motion. By eliminating the need for complex mechanical systems and enabling direct linear thrust, LIMs power everything from maglev trains to automated industrial systems. While challenges like high initial costs and efficiency losses exist, their benefits in speed, precision, and reliability make them indispensable in modern engineering. As technology advances, expect to see LIMs driving even more innovative applications worldwide.