In the era of high-precision automation and linear motion systems, position feedback must be not only fast, but also stable, accurate, and contactless. This is where the linear Hall effect sensor becomes a critical component in modern linear motors, robotics, and motion control applications.

More than just a magnetic sensor, a linear Hall effect sensor acts as the “eyes” of the system, providing continuous and proportional position feedback that enables smooth motion, precise control, and long-term reliability. So, what is a linear Hall effect sensor, how does it work, and why is it essential for linear motor solutions? Let’s explore these questions with ITG Linear Motor in the article below.

What Is a Linear Hall Effect Sensor?

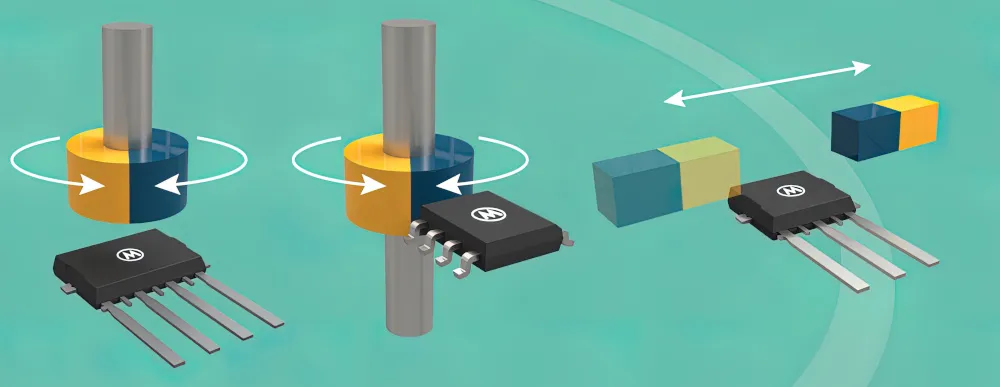

A linear Hall effect sensor is a type of magnetic sensor that measures the strength of a magnetic field and converts it into a continuous, proportional electrical output. Unlike digital Hall sensors that provide only ON/OFF signals, a linear Hall effect sensor delivers an analog output that varies linearly with the magnetic field intensity. This makes it especially suitable for precise position and displacement measurement in linear motion systems.

In practical applications, a linear Hall effect sensor works in combination with a permanent magnet. As the magnet moves relative to the sensor, the magnetic field experienced by the sensing element changes. The sensor then translates this change into a corresponding voltage or current signal, allowing the system to determine exact position, distance, or movement along a linear path.

What distinguishes a linear Hall effect sensor from other Hall-based devices is its high linearity and continuous feedback capability. The output signal maintains a predictable, proportional relationship with the magnetic field over a defined measurement range. This characteristic is critical in applications such as linear motors, servo systems, and motion control, where smooth motion and accurate closed-loop control are required.

Because the sensing principle is non-contact, linear Hall effect sensors offer excellent durability and reliability. They are not affected by mechanical wear, dust, oil, or vibration, making them ideal for industrial environments. Additionally, their compact size and simple integration allow them to be easily embedded into modern linear motor assemblies without adding mechanical complexity.

In summary, a linear Hall effect sensor is a robust, contactless position sensing solution that provides real-time, linear feedback, playing a vital role in achieving high precision, stability, and efficiency in advanced linear motion systems.

How Does a Linear Hall Effect Sensor Work?

A linear Hall effect sensor operates based on the Hall effect principle, which describes how a voltage is generated when an electric current flows through a conductor exposed to a magnetic field. This physical phenomenon allows the sensor to detect changes in magnetic field strength and convert them into a usable electrical signal.

At the core of the sensor is a Hall element, typically made from a semiconductor material. When a constant current passes through this element and a magnetic field is applied perpendicular to the current flow, the charge carriers are deflected. This deflection creates a small voltage, known as the Hall voltage, that is directly proportional to the magnetic field intensity.

In a linear Hall effect sensor, this Hall voltage is then processed by integrated signal conditioning circuitry, which amplifies, stabilizes, and linearizes the signal. The result is a continuous analog output, commonly a voltage or current, that changes proportionally as the magnetic field varies. This linear relationship is what enables accurate and repeatable position measurement.

In real-world applications, the sensor is paired with a moving permanent magnet. As the magnet travels along a linear path such as within a linear motor, the magnetic field at the sensor changes according to the magnet’s position. The sensor detects this change and produces a corresponding output signal, allowing the control system to calculate position, displacement, and direction of motion in real time.

Because the sensing process is entirely non-contact, there is no physical wear between components. This ensures long-term stability, high reliability, and consistent performance even in harsh industrial environments where dust, vibration, or temperature variations are present. As a result, linear Hall effect sensors are well suited for closed-loop control systems, where precise and continuous feedback is essential for smooth and accurate linear motion.

Key Characteristics of Linear Hall Effect Sensors

To fully understand why linear Hall effect sensors are widely used in high precision motion systems, it is important to examine their core performance characteristics. These factors directly influence measurement accuracy, system stability, and long term reliability in industrial applications.

1. High Linearity and Measurement Accuracy

One of the most critical characteristics of a linear Hall effect sensor is its high linearity, meaning the output signal changes proportionally with the magnetic field strength across a defined operating range. This predictable relationship allows control systems to translate sensor output into accurate position or displacement data.

High linearity ensures smooth motion control and minimizes signal distortion, which is especially important in closed loop systems such as linear motors and servo drives. When the sensor output remains consistent and proportional, system calibration becomes simpler and overall positioning accuracy is significantly improved.

2. Sensitivity and Resolution

Sensitivity defines how strongly the sensor responds to changes in the magnetic field. A well designed linear Hall effect sensor offers balanced sensitivity, enabling it to detect small position changes while avoiding signal saturation.

Higher sensitivity contributes to better resolution, allowing the system to identify fine movements with greater precision. This characteristic is essential in applications that require micro positioning or smooth velocity control, where even minor variations in motion must be detected and corrected in real time.

3. Temperature Stability and Signal Consistency

Industrial environments often involve fluctuating temperatures, which can affect electronic components. Linear Hall effect sensors are designed with temperature compensation mechanisms that maintain stable output across a wide temperature range.

By reducing thermal drift, these sensors provide consistent and reliable feedback regardless of operating conditions. This stability is crucial for maintaining precision over long operating periods and ensuring repeatable performance in demanding applications such as automation and industrial machinery.

4. Non Contact Operation and Durability

Because linear Hall effect sensors operate without physical contact between the sensing element and the moving magnet, they experience no mechanical wear. This non contact design significantly enhances durability and reduces maintenance requirements.

The absence of friction also allows the sensor to perform reliably in environments exposed to dust, oil, vibration, or moisture. As a result, linear Hall effect sensors are well suited for harsh industrial conditions where traditional contact based sensors may fail prematurely.

5. Flexible Output Options and Easy Integration

Linear Hall effect sensors typically provide analog output signals, such as voltage or current, that are easy to integrate with modern controllers, PLCs, and motion control systems. This flexibility simplifies system design and shortens development time.

In addition, their compact form factor allows seamless integration into linear motors and compact mechanical assemblies. This adaptability makes linear Hall effect sensors an efficient and practical solution for a wide range of linear motion applications.

Taken together, these characteristics explain why linear Hall effect sensors are a preferred choice for precise and reliable position sensing. Their combination of linearity, sensitivity, stability, durability, and integration flexibility enables high performance feedback in modern linear motion systems. As automation and precision requirements continue to increase, these sensors remain a foundational component in advanced motion control solutions.

Common Applications of Linear Hall Effect Sensors

Linear Hall effect sensors are widely used across industries thanks to their contactless operation, high reliability, and ability to deliver continuous position feedback. Their versatility allows them to adapt to both high precision and harsh operating environments, making them a key component in many modern systems.

- Linear motor position feedback, where continuous and accurate position sensing is required for closed loop control, smooth motion profiles, and precise force regulation.

- Servo systems and motion control platforms, enabling real time monitoring of displacement and velocity to improve dynamic response and positioning accuracy.

- Industrial automation and robotics, where linear Hall effect sensors support accurate joint movement, actuator positioning, and repeatable automated processes.

- Automotive applications, such as throttle position sensing, pedal travel measurement, and valve position monitoring, where durability and long term stability are essential.

- Industrial machinery and manufacturing equipment, including CNC machines, packaging lines, and material handling systems that operate in dusty, oily, or vibration heavy environments.

- Medical and laboratory equipment, where precise, smooth, and repeatable linear motion is required for imaging systems, diagnostic devices, and precision actuators.

- Consumer and smart devices, supporting linear displacement measurement in compact designs where space efficiency and reliability are critical.

As industries continue to move toward higher levels of automation and precision, linear Hall effect sensors remain a reliable and adaptable solution, delivering accurate position feedback across an ever expanding range of applications.

How to Choose the Right Linear Hall Effect Sensor

Selecting the right linear Hall effect sensor is a critical step in achieving accurate, stable, and reliable position feedback. The optimal choice depends not only on sensor specifications, but also on how well the sensor integrates with the overall linear motion system and operating environment.

Define Measurement Range and Accuracy Requirements

The first consideration is the required measurement range and positioning accuracy. The sensor must operate within a magnetic field range that fully covers the linear travel of the application. Higher precision applications demand sensors with excellent linearity and low output error, ensuring accurate position feedback throughout the entire stroke.

Understanding these requirements early helps prevent signal saturation, dead zones, or reduced resolution during operation.

Evaluate Sensitivity and Resolution

Sensitivity determines how effectively the sensor responds to changes in magnetic field strength. A properly matched sensitivity level ensures that small position changes are detected without introducing excessive noise or instability.

Higher resolution is particularly important in applications involving smooth velocity control or micro positioning. Selecting a sensor with balanced sensitivity allows for accurate feedback while maintaining signal stability under dynamic conditions.

Consider Environmental and Thermal Conditions

Operating environment plays a major role in sensor performance and longevity. Temperature fluctuations, vibration, dust, oil, and electromagnetic interference can all affect measurement reliability.

Choosing a linear Hall effect sensor with strong temperature compensation, robust packaging, and proven environmental resistance ensures consistent performance in demanding industrial environments and reduces long term maintenance risks.

Match Output Signal and System Compatibility

Linear Hall effect sensors typically provide analog outputs such as voltage or current signals. It is essential to ensure compatibility with the control system, PLC, or motion controller used in the application.

Matching output range, signal format, and power supply requirements simplifies integration, shortens development time, and minimizes the need for additional signal conditioning components.

Assess Mechanical Integration and Installation Constraints

Physical size, mounting method, and alignment tolerance should also be considered. The sensor must fit seamlessly within the mechanical design and maintain proper alignment with the magnetic source throughout operation.

Easy installation and stable mechanical integration reduce setup complexity and help maintain long term measurement accuracy in real world applications.

Conclusion

Linear Hall effect sensors have become an essential building block in modern linear motion and automation systems. By delivering continuous, contactless, and highly reliable position feedback, they enable smoother motion, greater accuracy, and long term system stability. From industrial automation and robotics to advanced linear motor solutions, these sensors play a crucial role in bridging physical movement with intelligent control.

As performance expectations continue to rise, choosing the right sensing technology is no longer just a technical decision but a strategic one. When properly integrated, linear Hall effect sensors help unlock the full potential of linear motors, optimizing efficiency, precision, and durability across demanding applications. With the right expertise and system design, they are not just components, but key enablers of next generation motion control solutions.