From car-assembling robots to ultra-precise medical devices, seamless linear motion is everywhere, yet often unnoticed. At the heart of this smooth and accurate movement are linear motion systems, the silent backbone of modern automation. But did you know there are multiple types of linear motion systems, each tailored to meet different industrial needs? In this article by ITG, we’ll break down the most common types, explore their strengths and limitations, and help you understand which system best fits your applications.

What Is a Linear Motion System?

A linear motion system is a mechanical solution designed to move a load or component in a straight line with controlled speed, accuracy, and efficiency. Unlike rotary systems that focus on circular motion, linear motion systems convert energy, usually electrical or mechanical, into linear displacement, making them indispensable in automation and precision engineering.

At its core, a linear motion system typically consists of several key elements:

- Linear guides or rails – provide a stable path for smooth movement.

- Bearings – reduce friction and ensure consistent motion.

- Actuators – generate and transmit force to create movement, often driven by screws, belts, or motors.

- Motors – supply the power source, such as servo motors or linear motors.

- Controllers – regulate motion, speed, and positioning to achieve high precision.

These systems are widely used in industries such as manufacturing, robotics, semiconductor production, and healthcare, where exact positioning, high repeatability, and reliable performance are critical. Their main advantages include enhanced productivity, reduced human error, and the ability to handle repetitive or high-precision tasks that would be difficult for manual processes.

Key Factors in Choosing a Linear Motion System

Selecting the right linear motion system is not just about technical specifications, it’s about finding the best match between performance requirements, cost, and long-term reliability. Below are the most important factors to consider:

1. Precision and Accuracy

For applications like semiconductor manufacturing, medical devices, or robotics, high precision and repeatability are critical. Systems such as ball screws or linear motors are designed to achieve micrometer-level accuracy.

2. Load Capacity

The weight and size of the load directly impact system choice. Heavy-duty applications, like CNC machines or industrial automation, often require rack-and-pinion or ball screw systems, while lighter loads may work well with belt-driven solutions.

3. Speed and Efficiency

Some industries demand extremely fast movement, while others prioritize smooth, controlled motion. Belt drives and linear motors excel at speed, whereas lead screws and ball screws focus on stability and torque.

4. Operating Environment

Dust, humidity, extreme temperatures, or cleanroom conditions can all influence performance. For instance, linear motors are ideal in clean, controlled environments, while lead screws may be more resilient in harsher industrial settings.

5. Maintenance and Durability

Consider the maintenance schedule and system longevity. Ball screws may need regular lubrication, while linear motors, thanks to their non-contact design, require less maintenance but come at a higher upfront cost.

6. Budget and Total Cost of Ownership

Initial investment is important, but so is the long-term cost of operation and upkeep. A system that seems inexpensive at first may lead to higher maintenance expenses over time. Evaluating the total cost of ownership ensures better financial decisions.

The Different Types of Linear Motion Systems

Linear motion systems come in a variety of designs, each tailored to specific applications, performance needs, and cost considerations. Understanding the strengths and limitations of each type is essential when choosing the right solution. Below are the most common types of linear motion systems, explained in detail.

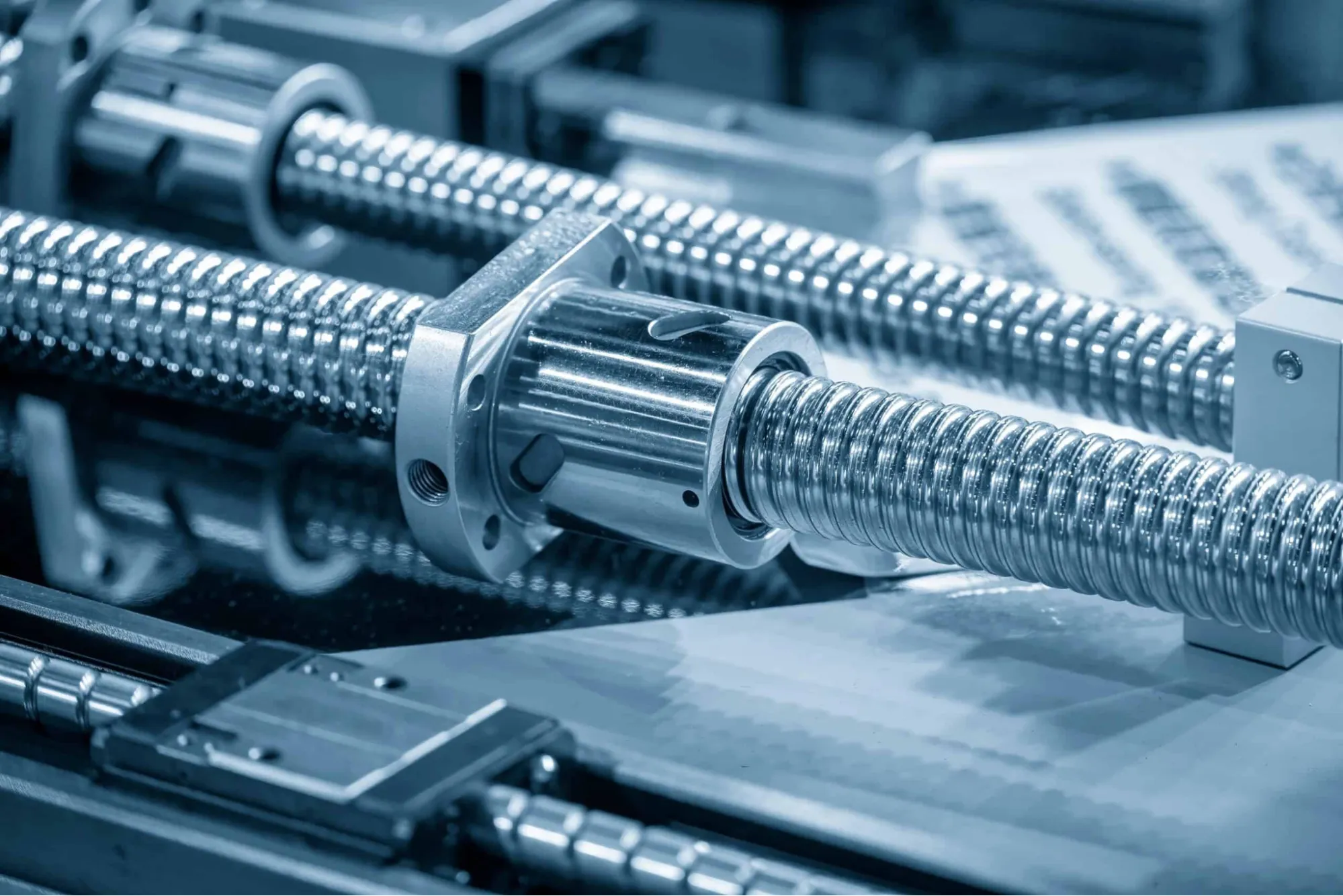

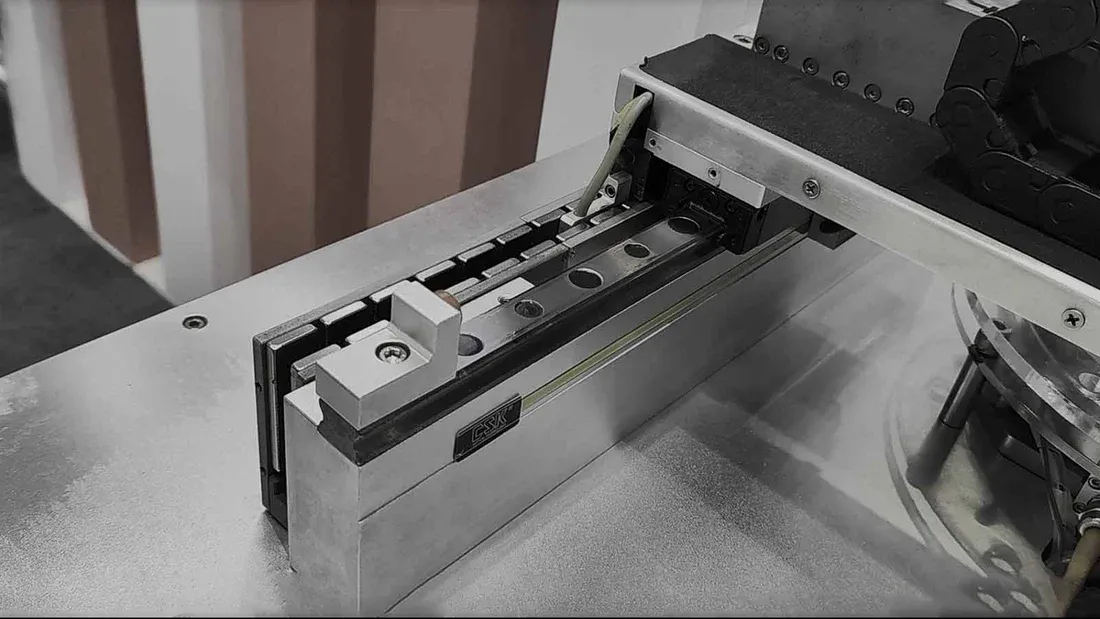

1. Ball Screw Linear Motion Systems

Ball screw systems use a threaded shaft and recirculating ball bearings to convert rotary motion into linear motion. They are well known for their high precision, excellent repeatability, and ability to handle heavy loads. These qualities make ball screws a popular choice in CNC machines, aerospace equipment, and industrial automation where accuracy is non-negotiable.

However, they require regular lubrication and maintenance to prevent wear and maintain smooth performance. Despite this, their balance of precision and load capacity keeps them among the most widely used solutions in modern manufacturing.

2. Belt Drive Linear Motion Systems

Belt-driven systems use a toothed or flat belt connected to pulleys to achieve linear motion. They are valued for their ability to achieve very high speeds over long distances at a relatively low cost. This makes them ideal for packaging lines, assembly processes, and pick-and-place applications where speed and efficiency matter more than ultra-fine accuracy.

The trade-off, however, is that belt drives typically lack the precision of ball screws or linear motors, and they may stretch or wear over time. Still, their affordability and simplicity keep them relevant for many industries.

3. Lead Screw Linear Motion Systems

Lead screws are similar to ball screws but instead use sliding contact between the screw and nut rather than recirculating balls. This design makes them quieter and more cost-effective, with minimal maintenance requirements.

They are best suited for applications that do not demand high speed or high accuracy, such as medical devices, laboratory equipment, and light-duty automation. The downside is their limited efficiency and faster wear under heavy loads, but their simplicity and low cost make them an attractive choice for low-demand applications.

4. Rack and Pinion Linear Motion Systems

Rack and pinion systems rely on a gear (pinion) that engages with a toothed rack to produce linear motion. This type of system excels in handling extremely heavy loads and long travel distances, making it common in heavy machinery, construction equipment, and large-scale CNC systems.

While they offer durability and strength, rack and pinion systems are less precise compared to other solutions. They are often chosen when power and travel distance outweigh the need for micrometer-level accuracy.

5. Linear Motor Systems

Among all the types of linear motion systems, linear motors represent the cutting edge of performance and innovation. Unlike other systems that rely on mechanical contact, a linear motor generates motion directly using electromagnetic force. This non-contact design eliminates friction, resulting in unmatched speed, precision, and smoothness.

Key advantages of linear motor systems include:

- Exceptional precision: Linear motors can achieve nanometer-level positioning accuracy, making them indispensable in industries where exact repeatability is critical.

- High speed and acceleration: With no mechanical transmission elements, linear motors can reach extremely high velocities and accelerate rapidly without losing control.

- Low maintenance: The absence of contact between moving parts minimizes wear and reduces the need for frequent servicing, lowering total cost of ownership.

- Smooth and quiet operation: Linear motors provide vibration-free motion, which is essential in semiconductor manufacturing, optical inspection, and medical applications.

These benefits explain why linear motor systems are increasingly adopted in advanced industries such as electronics manufacturing, precision robotics, medical imaging, and high-tech automation. Although they come with a higher upfront investment, the long-term gains in performance, reliability, and reduced downtime far outweigh the costs.

For companies seeking to maximize efficiency and quality in demanding environments, linear motor systems stand out as the superior choice. ITG, with its expertise in delivering high-performance linear motor solutions, supports businesses in implementing this advanced technology for sustainable success.

While ball screws, belt drives, lead screws, and rack-and-pinion systems continue to play important roles across industries, the evolution of technology is pushing many applications toward linear motors. Each system has its place, and the best choice depends on the specific requirements for precision, speed, load, and budget.

For organizations looking to achieve the highest standards of productivity and accuracy, investing in linear motor systems is a forward-thinking decision. With ITG as a trusted partner, businesses can access cutting-edge linear motion technology designed to power the next generation of automation.

Applications of Linear Motion Systems

Linear motion systems are used in a wide variety of industries. Each application calls for a different balance of speed, precision, and load capacity. Some of the most common uses include:

- Manufacturing and Industrial Automation

- CNC machining, packaging, and automated assembly rely on ball screws and rack-and-pinion systems for accuracy and durability.

- Belt-driven systems are often chosen for high-speed, long-travel production lines.

- Robotics and Material Handling

- Robotic arms and automated guided vehicles (AGVs) need smooth, repeatable motion.

- Linear motors excel in robotics thanks to their high acceleration, precision, and minimal maintenance.

- Semiconductor and Electronics Production

- Chip manufacturing and PCB assembly require nanometer-level accuracy.

- Linear motor systems dominate this sector, offering vibration-free, frictionless performance in cleanroom environments.

- Medical Devices and Healthcare

- Lead screws are used in compact diagnostic devices where simplicity and quiet operation are important.

- Linear motors provide precise, silent movement in MRI and CT scanners, surgical robots, and lab automation systems.

- Automotive and Aerospace Engineering

- Heavy-duty applications like welding, assembly, and inspection often rely on ball screws and rack-and-pinion systems.

- Linear motors are increasingly used for high-precision testing and advanced aerospace design.

- Research and Scientific Equipment

- Microscopy, spectroscopy, and nanotechnology experiments demand ultra-fine positioning.

- Linear motors and precision ball screws provide the reliability and control required for groundbreaking research.

From factory floors to research labs, linear motion systems form the backbone of countless applications. Traditional solutions like ball screws, belt drives, and rack-and-pinion setups remain critical, but the future is being shaped by linear motor systems. With ITG’s expertise in advanced linear motor technology, businesses can achieve unmatched performance and unlock new possibilities in automation and precision engineering.

How to Select the Right Linear Motion System

Choosing the right linear motion system isn’t just about picking from a catalog, it’s about finding the perfect balance between your project’s goals and the technology available. Every decision you make, from precision to speed, can impact performance, costs, and even long-term reliability.

The first question to ask yourself is: What does the application truly demand? A packaging line racing through thousands of cycles per day will have very different needs than a semiconductor machine that moves just a fraction of a millimeter with nanometer precision. Once you understand whether speed or accuracy is your top priority, the choices start to narrow.

Load capacity is another dealbreaker. If you’re moving heavy components, ball screws or rack-and-pinion systems often deliver the muscle you need. On the other hand, if your goal is ultra-smooth, high-speed motion with minimal wear, linear motors are the undisputed champion, combining power, precision, and longevity in a way no other system can.

But don’t overlook the environment. A dusty factory floor puts very different demands on a system compared to a cleanroom in a medical lab. Some systems require regular lubrication and maintenance, while others like frictionless linear motors: keep running with minimal intervention, reducing downtime and operating costs.

Ultimately, the smartest decision isn’t always the cheapest or the flashiest. It’s the system that aligns with your performance targets while staying reliable over the long haul. And here’s where a trusted partner makes all the difference. At ITG, we don’t just provide linear motor systems, we help engineers and manufacturers think strategically, weighing trade-offs and designing solutions that truly fit.

Conclusion

Linear motion systems may seem like hidden components, quietly driving machines behind the scenes, but in reality, they are the backbone of modern innovation. From factories that never stop running to laboratories pushing the limits of precision, these systems make progress possible by turning complex motion requirements into flawless performance.

What makes them truly exciting is the variety, each type has its own strengths, from the rugged endurance of ball screws to the unrivaled precision of linear motors. The real challenge lies not in choosing what looks best on paper, but in selecting the system that perfectly matches your goals, your environment, and your vision for the future.

At ITG, we believe linear motion is more than just mechanics; it’s a catalyst for innovation. With our expertise in advanced linear motor solutions, we help businesses unlock efficiency, precision, and long-term reliability, ensuring every motion counts.