High-torque demands call for high-performance solutions and only two types of AC motor consistently meet the challenge. Whether you’re operating industrial presses, electric vehicles, or precision automation, understanding the difference between the squirrel cage induction motor and the permanent magnet synchronous motor (PMSM) can save you from underpowered systems and costly inefficiencies.

This guide unpacks how each motor delivers torque, where they excel, and how to choose the one that aligns with your performance goals.

What is an AC Motor?

An AC motor, or alternating current motor, is the driving force behind modern industry and automation. It’s a type of electric motor that converts alternating current (AC) electrical energy into mechanical motion with efficiency, precision, and power. Whether it’s running conveyor belts in factories, driving pumps in water systems, or powering your home appliances, the AC motor is everywhere. And for good reason: it’s reliable, energy-efficient, and adaptable to a vast range of applications.

How Does an AC Motor Work?

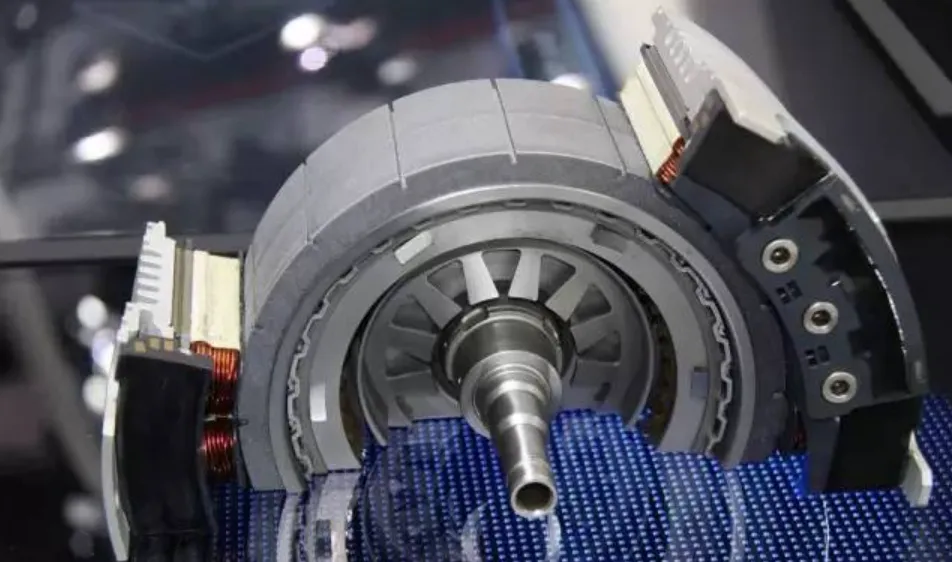

At its core, an AC motor consists of two fundamental components:

- Stator (the stationary part) – it produces a rotating magnetic field when AC electricity flows through its windings.

- Rotor (the rotating part) – it responds to the magnetic field, producing torque and rotational motion.

This elegant interplay between magnetic fields and electric current is what allows the AC motor to deliver consistent and powerful motion with minimal mechanical complexity.

Types of AC Motors You Should Know

There are two main types of AC motors, and understanding their differences is critical for choosing the right one for your needs:

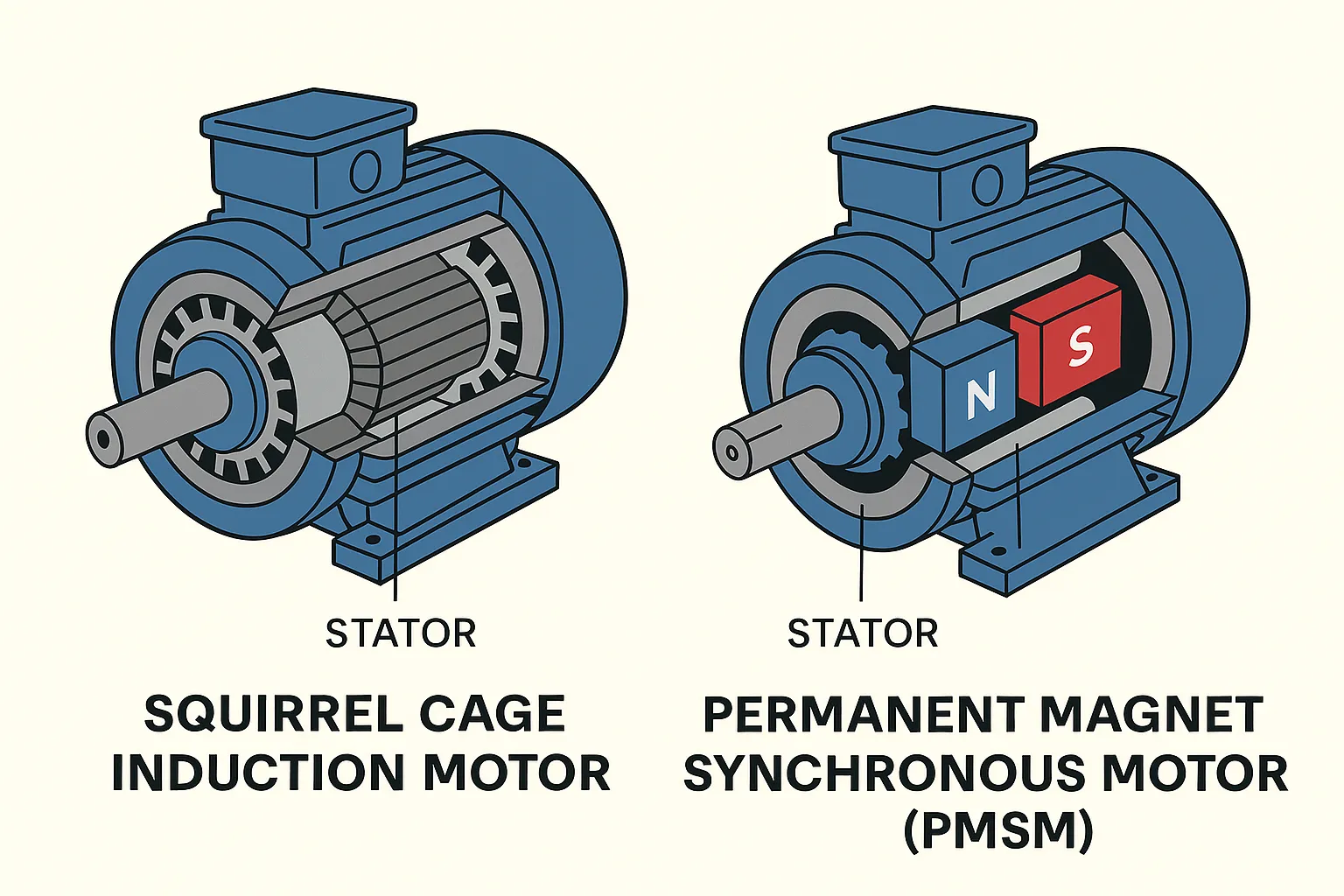

1. Induction Motor (Asynchronous AC Motor)

The induction motor is the workhorse of modern industry. It’s called “asynchronous” because the rotor does not rotate at exactly the same speed as the magnetic field. Known for its simplicity, low maintenance, and ruggedness, this motor is ideal for high-load, continuous-duty applications such as compressors, fans, and pumps.

2. Synchronous AC Motor

In contrast, a synchronous AC motor rotates at the same speed as the stator’s magnetic field hence the name. This precision makes it perfect for applications that demand constant speed under varying loads. It’s widely used in robotics, automated manufacturing, and any setup where timing and control are critical.

Why can motors matter in the modern world?

AC motors are more than just components, they’re productivity multipliers. They reduce energy costs, minimize downtime, and deliver consistent performance across industries. From heavy-duty machines in factories to the air conditioning system in your office, AC motors are what keep the world moving.

Type 1 – Squirrel Cage Induction Motor

Among all the types of AC motor, the squirrel cage induction motor is by far the most widely used and trusted in heavy-duty industrial environments. It is a true workhorse known for its durability, simplicity, and ability to deliver high starting torque without complex control systems.

Construction and Working Principle

The squirrel cage induction motor is a subtype of AC motor with a rotor design that looks like a cage hence the name. It operates based on electromagnetic induction, meaning it does not require electrical contact between the stator and rotor.

- Stator: Generates a rotating magnetic field when powered by AC.

- Rotor (Squirrel Cage): Made of conductive bars short-circuited by end rings. The magnetic field from the stator induces current in the rotor, producing torque.

This structure makes the motor highly robust and virtually maintenance-free compared to brushed motors or more complex systems like a synchronous AC motor.

Why it delivers High Starting Torque

One of the key advantages of squirrel cage induction motors is their ability to produce high starting torque, making them ideal for applications that demand strong initial force.

- Slip Principle: The rotor initially lags behind the rotating magnetic field (asynchronous operation), creating strong electromagnetic induction and torque.

- Instant Torque Response: No delay in startup, suitable for loads that require immediate motion or resistance.

This makes them a preferred choice where what is AC motor isn’t just a theoretical question — it’s a practical solution for power-demanding systems.

Advantages that matter

If you’re choosing among the many types of AC motor, this one stands out for practical, bottom-line reasons:

- Simplicity: No brushes, commutators, or external excitation.

- Durability: Withstand harsh environments — dust, moisture, temperature.

- Low Maintenance: Less wear and tear means lower lifetime cost.

- Cost-Effective: Affordable to produce, install, and operate.

Compared to a synchronous AC motor, the squirrel cage design requires less precise control systems and is easier to integrate into existing setups.

Common applications

Thanks to its high starting torque and durability, this motor is widely used in industries where power and reliability are non-negotiable:

- Hydraulic presses

- Centrifugal pumps

- Industrial fans and blowers

- Air compressors

- Heavy-duty conveyor belts

- Hoisting and lifting machinery

Wherever brute force meets simplicity, the squirrel cage induction motor delivers.

Type 2 – Permanent Magnet Synchronous Motor (PMSM)

Among all the types of AC motor, the Permanent Magnet Synchronous Motor (PMSM) is the top-tier solution when precision, efficiency, and consistent torque delivery are critical. This is not just another AC motor, it is the future-facing answer for high-performance applications demanding intelligent motion control.

How it works

The PMSM is a synchronous AC motor that operates based on a rotating magnetic field, just like any other ac motor. However, what sets it apart is the rotor; it contains permanent magnets instead of relying on induced currents.

- The stator generates a rotating magnetic field using AC input.

- The rotor, embedded with permanent magnets, locks into synchronization with the stator’s field.

- Because the rotor and stator rotate in perfect sync, there is no slip, which results in stable speed and accurate control.

Unlike induction motors, where torque is produced by slip and induced current, the PMSM eliminates inefficiencies by maintaining precise synchronization. That’s why it is considered one of the most advanced types of AC motor in the market today.

Stable High Torque even at Low Speeds

If you need reliable torque across the entire speed range, especially at low RPMs, PMSM delivers results that induction motors simply cannot match.

- The constant magnetic field in the rotor ensures that torque is immediately available, even at startup or low rotational speeds.

- There is no drop-off or delay, making it ideal for applications that require precision motion from zero speed.

This capability transforms what is usually a limitation in other AC motors into a strategic advantage.

High Efficiency and Precise Control

The PMSM offers significantly higher efficiency than a traditional induction motor. Less heat, lower losses, and smoother performance translate into real savings in energy and maintenance.

- Works perfectly with variable frequency drives (VFDs) or servo drives, enabling advanced speed and torque control.

- Maintains constant torque and speed under variable load conditions.

- Reduces wear and prolongs lifespan due to lower thermal stress and fewer moving parts.

Compared to other synchronous AC motor types, PMSM takes performance a step further by removing the need for external excitation or complex control gear.

Ideal applications

Because of its superior control, torque, and efficiency, PMSM is now the go-to motor in smart, high-precision industries:

- CNC machines require sharp torque control and position accuracy.

- Industrial robots where responsive movement and synchronization are non-negotiable.

- Electric vehicles (EVs) for their instant torque and power density.

- Automated conveyor systems demanding consistent load performance.

These are environments where downtime is unacceptable, precision is mission-critical, and performance must be optimized every second.

Choosing the Right High-Torque AC Motor – Comparison & Selection Guide

Selecting the ideal AC motor for high torque motors applications is more than a technical task. It’s a strategic decision that determines the efficiency, performance, and long-term cost of your operation. When it comes to raw torque, reliability, and energy precision, two main players dominate the scene: the Squirrel Cage Induction Motor and the Permanent Magnet Synchronous Motor (PMSM).

Let’s break down how these two types of AC motor compare and more importantly, when to choose one over the other.

Performance comparison table

| Criteria | Squirrel Cage Induction Motor | Permanent Magnet Synchronous Motor (PMSM) |

| Starting Torque | Very high torque at startup | High and stable, even at low speed |

| Efficiency | Moderate to good | Superior energy efficiency |

| Speed Control | Limited without VFD, less precise | Exceptional with servo/VFD integration |

| Investment & Operating Cost | Lower initial cost, minimal maintenance | Higher cost, but lower energy consumption |

| Best-Suited Applications | Heavy machinery, pumps, conveyors | Robotics, CNC, EVs, automated precision systems |

This comparison highlights a fundamental truth in what is AC motor selection: torque is only part of the equation. Long-term performance, control accuracy, and energy efficiency matter just as much especially in modern, tech-driven systems.

Guidance on making the right choice

Choose the Squirrel Cage Induction Motor if:

- You need very high starting torque to move heavy loads immediately.

- Your environment is dusty, hot, or industrial. This motor can handle harsh conditions with minimal maintenance.

- You’re operating on a tight budget and require a cost-effective, durable solution.

Your system doesn’t require precise speed control; basic variable speed is enough.

This is the motor that just works. Rugged, reliable, and ready for heavy lifting.

Choose the Permanent Magnet Synchronous Motor (PMSM) if:

- Your application requires high torque at low speeds with minimal fluctuation.

- You need tight control over speed and torque, such as in robotics or CNC machinery.

- Energy savings and long-term efficiency are essential to your operation.

- You’re building a smart system with servo drives or advanced automation.

This is the motor for next-generation precision. Efficient, intelligent, and built for control.

Conclusion

This isn’t about which motor is better, it’s about which one is right for you. If you need cost-effective startup power, go with the induction motor. If your system demands accuracy, speed stability, and energy savings, choose the PMSM. Either way, picking the right high-torque AC motor is how you move faster, stronger, and smarter in every application.