In a world where milliseconds define productivity and precision dictates quality, motion technology has quietly entered a new era. The high frequency response linear motor isn’t just another engineering upgrade, it’s the invisible force behind the machines shaping our future. From semiconductor lines to high-speed packaging systems, this innovation is redefining how industries move, measure, and manufacture. In this article, we’ll uncover the top industrial applications where these high-performance motors don’t just keep pace, they set the standard.

What Is a High Frequency Response Linear Motor?

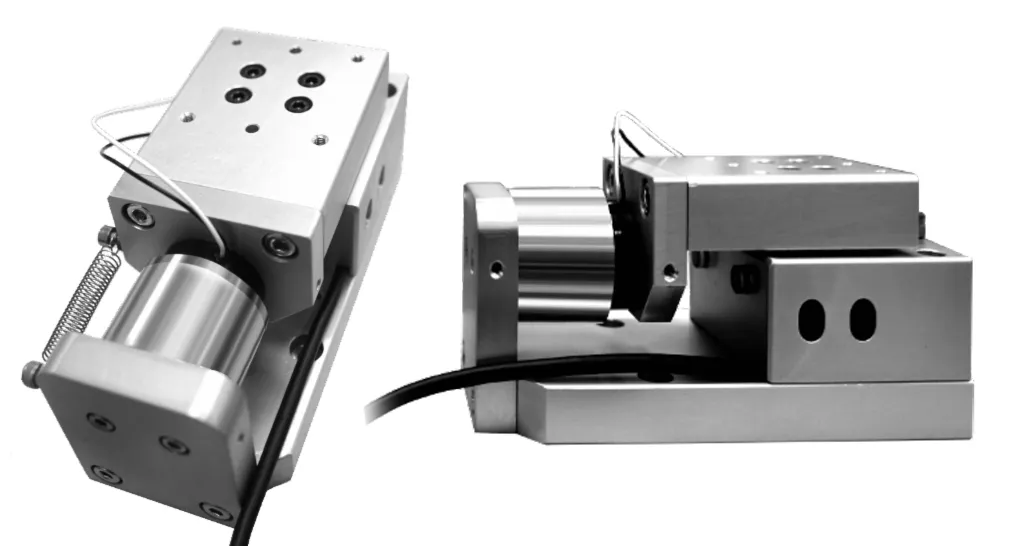

At its core, a linear motor is a direct-drive system that converts electrical energy straight into linear motion, no gears, no screws, no belts. Instead of rotating a shaft like traditional motors, it generates motion along a straight line, creating a clean, frictionless, and ultra-responsive movement.

Now, when we add “high frequency response” to the equation, we’re talking about a motor that reacts instantly to control signals, often in milliseconds. In motion control terms, this refers to the system’s servo bandwidth, how quickly the motor can respond to command changes or external disturbances. A high frequency response linear motor therefore achieves faster acceleration, higher positioning accuracy, and smoother motion than standard linear motors.

Imagine a pick-and-place robot on a semiconductor line that must move thousands of times per minute, each motion must start, stop, and realign with microscopic accuracy. A motor with low frequency response would struggle to keep up, resulting in vibration or delay. But with high frequency response, the motor executes every command in near real-time, ensuring tight motion control and zero lag between input and action.

This technology also eliminates many mechanical limitations. Without ball screws or belts, there’s no backlash, no frictional loss, and no need for frequent maintenance. The motor’s moving coil or magnet assembly glides effortlessly on an air or magnetic bearing system, delivering a perfectly linear path of motion.

In short, a high frequency response linear motor represents the pinnacle of precision and agility in motion engineering, enabling machines to move not only faster, but also smarter, with stability and control at every microsecond of the process.

Top Industrial Applications of High Frequency Response Linear Motors

From semiconductor production to robotics and precision metrology, high frequency response linear motors are quietly transforming the backbone of modern industry. Their ability to combine speed, precision, and reliability makes them indispensable in fields where every microsecond and micron matter.

Let’s explore the industries where these motors are making the biggest impact.

1. Semiconductor and Electronics Manufacturing

In the semiconductor world, accuracy is everything. During wafer inspection, die bonding, or micro-assembly, even the slightest delay or vibration can compromise yield.

High frequency response linear motors deliver nanometer-level positioning accuracy and ultra-fast servo response, enabling rapid step-and-repeat motion without overshoot.

By eliminating mechanical transmission elements like screws or belts, they minimize friction and hysteresis, ensuring smooth, repeatable motion for 24/7 production.

These motors are found in:

- Wafer and die bonding systems

- PCB drilling and routing machines

- Precision optical alignment stages

- Pick-and-place robots for chip assembly

The result: higher throughput, tighter process control, and consistent product quality.

2. Laser Processing and Precision Machining

Laser systems and CNC machines demand not just speed, but motion uniformity at extreme frequencies. When cutting, engraving, or etching, even micro-vibrations can ruin surface finish.

High frequency response linear motors excel here by providing instant acceleration and deceleration, allowing cutting heads to follow complex contours at high speed with flawless edge quality.

Applications include:

- Laser cutting and engraving equipment

- Micro-machining for medical devices or optics

- High-speed CNC positioning tables

By reducing settling time between movements, manufacturers can shorten cycle times, a direct gain in productivity and profitability.

3. High-Speed Packaging and Printing Systems

Packaging and printing lines are built for one goal: throughput. Every second counts. Machines must start, stop, and reposition hundreds of times per minute, all while maintaining perfect registration.

That’s where high frequency response linear motors shine. Their rapid feedback and precise control allow packaging heads or print carriages to move at lightning speed with minimal vibration.

They’re used in:

- High-speed carton forming and sealing

- Flexible packaging machines

- Digital and offset printing systems

The outcome is smoother operation, reduced maintenance, and significantly faster cycle rates without sacrificing accuracy.

4. Metrology and Inspection Equipment

In metrology, precision isn’t measured in millimeters, it’s in microns or even nanometers. Systems like coordinate measuring machines (CMMs), optical profilers, and inspection scanners require vibration-free, stable motion.

Linear motors with high frequency response ensure rapid positioning without oscillation, which means measurement data is both fast and reliable.

They enable:

- Fast scanning of large surfaces

- Stable data collection under dynamic conditions

- High repeatability for automated inspection systems

By combining high dynamic stiffness with smooth motion, these motors deliver the consistency critical for advanced quality control.

5. Robotics and Advanced Automation

Today’s robots, especially in high-precision assembly or laboratory automation, rely on direct-drive linear motors to achieve clean, fast, and silent movement.

In collaborative robotics (cobots) or automated handling systems, high frequency response ensures that every motion follows the control signal instantly, enhancing safety, speed, and repeatability.

Common uses include:

- Pick-and-place units for assembly lines

- Medical and pharmaceutical automation

- Precision transport in cleanroom environments

These motors not only increase cycle speed but also simplify the robot’s design, reducing wear, noise, and maintenance needs.

6. Research and Laboratory Instruments

Scientific research demands motion systems that can react to micro-adjustments with zero delay. Whether aligning optical lenses, scanning biological samples, or testing micro-components, stability and responsiveness are crucial.

High frequency response linear motors provide that delicate balance between speed and stability, making them the preferred choice for advanced instruments such as:

- Microscopes with automated stages

- Spectroscopy and interferometry systems

- Optical alignment and calibration platforms

Their silent, frictionless motion ensures measurements remain uncontaminated by mechanical noise or vibration.

7. Emerging Fields and Future Applications

Beyond traditional industries, these motors are gaining traction in next-generation technologies like additive manufacturing, battery cell production, and autonomous test equipment.

As systems demand more agility, accuracy, and speed, high frequency response linear motors are becoming the foundation of Industry 4.0 motion control, adaptable, intelligent, and built for extreme precision.

In essence, wherever speed meets accuracy, you’ll find a high frequency response linear motor at work, powering the world’s most advanced machines to move with unprecedented control and efficiency.

Why Does ITG Linear Motor Excels Across These Applications?

The reason why the ITG Linear Motor line truly excels across demanding industrial applications lies in a combination of deep engineering excellence, tailored solutions, and a performance-first mindset.

From the foundation up, ITG designs and manufactures linear motors and direct-drive systems that are built to meet ultra-high demands: whether it’s high force density, rapid acceleration, or extreme motion precision. On their product page you’ll find product families like Ironcore Linear Motors (designed for high force and thermal performance), Ironless Linear Motors (for ultra-smooth, cog-free motion), Torque Motor and custom motors crafted for specific needs.

What distinguishes ITG’s motors in high frequency response applications is how these factors combine:

1. High dynamic responsiveness

In applications where motion must begin-stop millions of times or follow extremely tight positioning profiles, the motor’s ability to react rapidly is key. ITG’s motors are engineered for that: low moving mass, high stiffness, and minimal mechanical transmission elements mean the system can respond almost instantaneously to control commands.

2. Minimal mechanical compromise

Because their motors eschew traditional elements like ball screws, belts or chain drives, you eliminate backlash, friction-induced delay and mechanical hysteresis. For industries demanding ultra-tight repeatability and fast settle times, that matters enormously.

3. Thermal and mechanical robustness

Continuous high-frequency operation generates heat and mechanical stress. ITG addresses this via high-force-density designs, excellent thermal performance (especially in their iron-core variants), and vacuum versions for environments with strict cleanliness and thermal control. This means fewer failures, less downtime, and consistent performance even in 24/7 production.

4. Proven industrial performance

ITG explicitly targets the key markets where high frequency response matters: printing, digital cutting, semiconductor, science & aerospace, robotics, automotive testing. Their product roadmap and application categories reflect exactly the industries where speed, precision and bandwidth set the bar.

From a business perspective, choosing ITG means you’re investing in motion systems that deliver higher throughput, better accuracy, lower maintenance and less downtime. In short: you’re not just buying a linear motor, you’re buying a motion system engineered to meet the demands of next-generation automation.

Conclusion

High frequency response linear motors have become a key enabler of advanced automation, empowering industries to achieve new levels of speed, precision, and efficiency. With its deep expertise and innovative product lineup, ITG Linear Motor delivers solutions that adapt seamlessly to demanding industrial needs. From design to performance, ITG doesn’t just move machines, it drives progress.