In the fast-evolving world of modern automation, small linear motors are quietly driving a revolution. These compact yet powerful motion devices deliver exceptional precision, speed, and control, qualities that are transforming how robots, semiconductor tools, and precision instruments operate. As industries demand smaller, smarter, and more efficient systems, small linear motors have become the go-to solution for engineers seeking seamless performance in limited spaces. Let’s explore where these miniature motion powerhouses are making the biggest impact today.

Understanding Small Linear Motors and Their Key Advantages

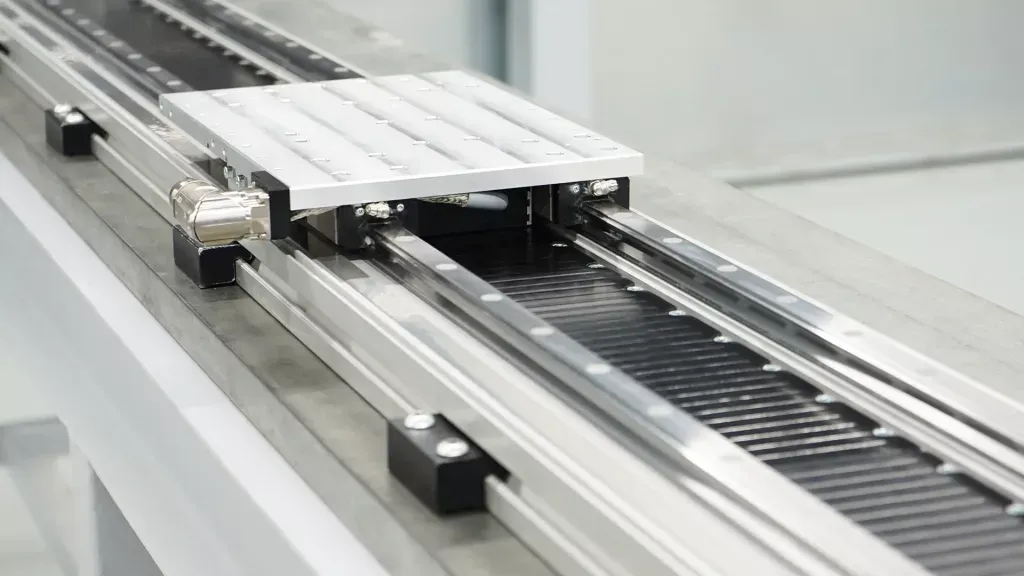

At their core, small linear motors are advanced motion devices designed to convert electrical energy directly into linear motion, without the need for mechanical transmission components such as gears, screws, or belts. Unlike traditional rotary motors that require additional mechanisms to produce linear movement, linear motors drive the load directly along a straight path. This direct-drive principle not only enhances efficiency but also minimizes energy loss and mechanical wear.

A small linear motor typically consists of two main parts: a stator (which contains the coils that generate a magnetic field) and a forcer or mover (which glides along the stator to create motion). This simple yet powerful design allows for smooth, precise, and repeatable positioning, ideal for compact automation systems where accuracy is critical.

Key Advantages of Small Linear Motors

1. Compact Size for Space-Limited Designs: Their slim and lightweight structure makes small linear motors perfect for machines with tight installation spaces, such as micro-robots, semiconductor tools, and laboratory instruments.

2. High Speed and Acceleration: Thanks to the absence of mechanical coupling, small linear motors can achieve rapid acceleration and deceleration, enabling faster production cycles and improved throughput.

3. Unmatched Precision and Repeatability: With direct-drive motion control, these motors deliver sub-micron positioning accuracy, making them indispensable for industries that demand precise alignment, inspection, or assembly.

4. Smooth, Frictionless Movement: The linear motion is achieved magnetically, eliminating the need for contact-based components. This results in vibration-free and noiseless operation, ideal for cleanrooms and precision environments.

5. Low Maintenance and Extended Lifespan: Without mechanical wear parts such as screws or belts, small linear motors require minimal maintenance, offering long-term reliability and reduced downtime for automation systems.

6. Energy Efficiency and Smart Control Integration: Modern small linear motors are easily integrated with servo drives and digital controllers, allowing intelligent feedback, precise velocity control, and energy optimization across production lines.

In essence, small linear motors represent the next generation of compact motion technology, combining performance, precision, and durability in a single, space-efficient design. For companies like ITG, these advantages form the foundation of their innovation, enabling industries worldwide to build smaller, faster, and smarter automation systems.

Top 6 Industrial Applications of Small Linear Motors

Small linear motors are now at the heart of many modern automation systems. Their compact size, precision, and high-speed capabilities make them a preferred choice in industries that demand smooth motion and accurate positioning. Below are the most common industrial sectors where small linear motors have proven their value.

1. Semiconductor Manufacturing Equipment

In the semiconductor industry, accuracy and cleanliness are essential. Small linear motors play a critical role in wafer handling, alignment, and inspection systems, where even the smallest vibration can affect product quality.

Their contactless and maintenance-free design ensures smooth, particle-free motion that meets strict cleanroom standards. The result is higher throughput, consistent quality, and reduced downtime in advanced chip production.

2. Robotics and Collaborative Robots (Cobots)

Compact automation solutions such as cobots rely on lightweight and responsive motion control. Small linear motors provide the agility and precision needed for pick-and-place operations, micro-assembly, and packaging tasks.

Because they can deliver fast, repeatable movement with minimal vibration, these motors are ideal for robots working closely with humans or operating in confined spaces.

3. Medical and Laboratory Automation

In medical devices and laboratory systems, reliability and precision are non-negotiable. Small linear motors are used in diagnostic instruments, DNA analyzers, and precision dispensing systems.

Their smooth and quiet operation makes them suitable for sensitive environments, while their non-contact design minimizes contamination risks. This ensures dependable, repeatable motion in applications that directly impact human health.

4. Electronics and PCB Assembly Lines

Electronics manufacturing demands high-speed and ultra-accurate component handling. Small linear motors enable smooth positioning for inspection stages, PCB alignment, and soldering automation.

Their consistent motion control improves product quality and reduces mechanical wear compared to traditional motor-driven mechanisms. Manufacturers benefit from greater production efficiency and long-term stability.

5. Printing, Packaging, and Textile Automation

In industries that rely on repetitive linear movements, such as printing, packaging, and textiles, small linear motors ensure consistent motion over long cycles. Their precise synchronization enhances printing accuracy, optimizes packaging speed, and minimizes material waste. Their small footprint also helps machine designers build more compact and energy-efficient systems.

6. Precision Instruments and Optical Devices

Emerging applications include precision instruments, microscopes, and camera alignment systems that require micro-level motion. Small linear motors offer exceptional stability for fine adjustments and positioning tasks. Their ability to perform extremely smooth, step-less movements is key to achieving high measurement accuracy in research and optical equipment.

Small linear motors have become an essential building block for automation systems that prioritize speed, precision, and reliability. From semiconductor lines to laboratory instruments, they are reshaping how industries move, measure, and manufacture. ITG continues to push this evolution forward, providing innovative linear motion solutions tailored to the needs of compact automation.

Why Small Linear Motors Are Transforming Modern Automation

The shift toward smaller, smarter, and more efficient machines is redefining the landscape of industrial automation. At the core of this transformation lies the small linear motor, a technology that enables faster, cleaner, and more precise motion than traditional mechanical systems.

One of the main reasons small linear motors are reshaping automation is their direct-drive technology. By eliminating components like gears and belts, engineers can design compact machines with fewer moving parts, less friction, and higher responsiveness. This results in smoother motion control, faster acceleration, and superior positioning accuracy, all key factors in modern high-speed production environments.

Another crucial factor is energy efficiency. Small linear motors consume less power while maintaining consistent performance, making them an ideal fit for sustainable and cost-efficient manufacturing systems. Their minimal maintenance requirements also reduce downtime and extend machine lifespan, which translates into long-term savings for manufacturers.

The rise of smart factories and digital integration further amplifies their impact. Small linear motors are easily combined with advanced controllers, sensors, and feedback systems to enable intelligent motion control and real-time monitoring. This compatibility with Industry 4.0 standards allows for predictive maintenance, data-driven optimization, and seamless communication between machines.

In essence, small linear motors are not just improving automation, they are enabling the next generation of compact, intelligent, and high-performance industrial systems. By integrating this technology, companies can build equipment that is faster, cleaner, and more adaptable to future production demands.

Emerging Uses in Precision Instruments and Micro Devices

In the realm of micro-scale engineering, small linear motors are redefining what precision truly means. Their ability to deliver highly accurate, frictionless, and repeatable linear motion makes them indispensable in instruments that demand microscopic precision, far beyond the capabilities of conventional motion systems.

One of the most notable fields embracing these motors is semiconductor manufacturing, where even nanometer deviations can lead to costly defects. Small linear motors enable ultra-fine positioning of wafers and lithography stages, improving throughput and yield without compromising precision.

Beyond semiconductors, medical device engineering has also begun integrating compact linear motors into diagnostic and surgical tools. From automated microfluidic systems that analyze biological samples to robot-assisted surgical devices performing microscale movements inside the human body, these motors offer both stability and control in critical applications.

In the world of optics and metrology, small linear motors are empowering next-generation devices such as laser alignment systems, precision scanning microscopes, and nano-measurement tools. Their ability to deliver smooth motion without mechanical backlash ensures the highest measurement fidelity and repeatability.

Finally, as wearable technology and consumer electronics continue to miniaturize, the integration of small linear motors into haptic systems, autofocus mechanisms, and vibration feedback units opens the door to more responsive and immersive user experiences.

In short, small linear motors are not just powering machines, they’re enabling innovation at the micro level, driving the next leap in precision technology and intelligent design.

Conclusion

Small linear motors may be compact in size, but their impact on modern automation is monumental. By merging precision, speed, and efficiency into one seamless motion technology, they’re not just improving existing systems, they’re redefining the boundaries of engineering innovation.

From industrial robotics and semiconductor manufacturing to medical instruments and micro devices, these motors are quietly driving a revolution in how machines move, sense, and perform. Their minimal wear, exceptional responsiveness, and compact footprint make them the cornerstone of future-ready automation systems.

As industries push toward miniaturization, smart manufacturing, and sustainable operation, small linear motors will continue to play a pivotal role, powering the next generation of devices that are not only more accurate, but also more intelligent and adaptive than ever before.