When evaluating motor performance, torque specifications often appear straightforward, until real-world operation proves otherwise. Many engineers focus on peak torque as a measure of power, only to encounter overheating, unstable motion, or premature motor failure in continuous applications. The key issue lies in understanding the fundamental difference between rated torque and peak torque.

These two values describe very different operating conditions, and misinterpreting them can directly impact efficiency, reliability, and system lifespan. In this article, we break down what rated torque and peak torque truly mean, how they influence motor performance, and which specification matters most for demanding motion control and linear motor applications.

Understanding Torque in Motor Performance

Torque is one of the most fundamental parameters defining how a motor performs under load. In simple terms, torque represents the rotational force a motor can generate to move, accelerate, or hold a mechanical system against resistance. Regardless of motor type: servo, stepper, or linear motor, torque directly determines how effectively the motor converts electrical energy into mechanical motion.

In practical applications, torque influences several critical aspects of motor performance. It affects how quickly a system can accelerate, how well it maintains speed under varying loads, and how stable motion remains during continuous operation. Insufficient torque can lead to stalled motion, positioning errors, or excessive stress on mechanical components, while excessive torque, especially when poorly managed, can cause overheating and reduce motor lifespan.

From a system design perspective, torque is never an isolated value. It must be evaluated in relation to load inertia, duty cycle, speed requirements, and thermal limits. Understanding torque in this broader context is essential for selecting a motor that delivers not just peak capability, but consistent and reliable performance over time.

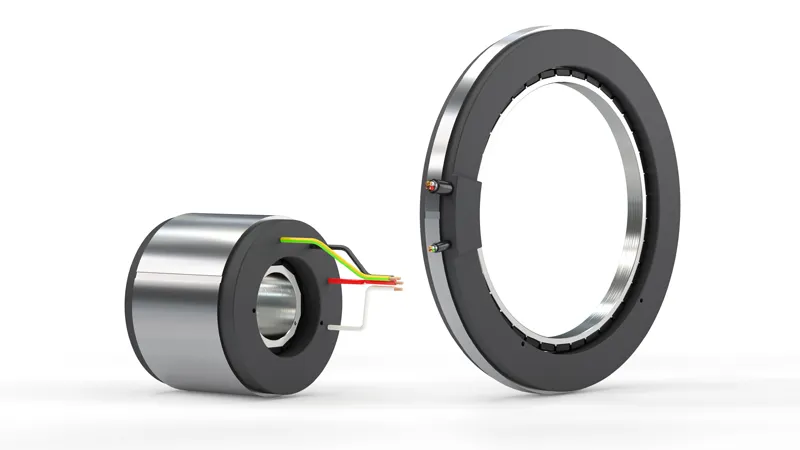

What Is Torque Motors?

In motor terminology, torque refers to the force that causes rotation around an axis, typically measured in newton-meters (Nm) for rotary motors. It defines the motor’s ability to do mechanical work, such as driving a shaft, moving a load, or maintaining position under resistance.

A torque motor is generated when electrical current interacts with the motor’s magnetic field. The magnitude of this torque depends on factors such as motor design, current level, magnetic flux, and cooling conditions. As current increases, torque increases but so does heat, which introduces thermal limitations that must be carefully managed.

For linear motor systems, torque is often translated into linear force rather than rotational motion. While the unit of measurement changes from torque to force, the underlying principle remains the same: it represents the motor’s ability to overcome load and deliver controlled motion. This distinction is especially important in precision automation, where consistent force output directly affects accuracy, repeatability, and system stability.

By clearly understanding what torque means in motors and how it is generated, engineers can better interpret rated torque and peak torque specifications, laying the foundation for informed motor selection and optimized performance.

What Is Rated Torque?

Rated torque, also known as continuous torque, refers to the amount of torque a motor can deliver continuously without exceeding its thermal limits. This value is defined under specified operating conditions, where the motor reaches thermal equilibrium and can operate reliably over long periods without degradation.

Unlike short-term performance figures, rated torque reflects the motor’s true working capability in real-world applications. It represents the level of mechanical output that can be sustained while maintaining acceptable winding temperature, insulation integrity, and overall system stability.

Rated Torque and Thermal Equilibrium

Rated torque is fundamentally linked to heat generation and dissipation. As a motor produces torque, electrical losses, primarily copper losses, generate heat within the windings. Rated torque is determined at the point where heat generation equals heat dissipation, ensuring that the motor temperature remains within safe limits.

Operating a motor at or below its rated torque allows it to run continuously without overheating. Exceeding this value for extended periods, however, can lead to excessive temperature rise, reduced efficiency, and accelerated wear of internal components.

Why Rated Torque Defines Continuous Performance

In most industrial and automation systems, motors are required to operate for extended durations rather than in short bursts. Rated torque defines how much load a motor can handle under these continuous operating conditions. It directly influences system reliability, energy efficiency, and service life.

Applications such as conveyor systems, production lines, and precision linear motion stages depend heavily on rated torque rather than peak torque. In these scenarios, stable and predictable performance is far more critical than momentary power output.

Rated Torque in Linear Motor Applications

For linear motor systems, rated torque is often expressed as continuous force rather than rotational torque. This continuous force rating determines the motor’s ability to maintain smooth, accurate motion over long cycles without thermal instability.

Because linear motors frequently operate in high-precision environments, consistent force output is essential for maintaining positioning accuracy and repeatability. Selecting a linear motor with sufficient rated torque (or continuous force) ensures long-term performance stability, especially in applications involving constant load or frequent duty cycles.

Key Engineering Considerations When Evaluating Rated Torque

When assessing rated torque, engineers should consider:

- Duty cycle and operating time

- Ambient temperature and cooling conditions

- Load characteristics and mechanical resistance

- Required accuracy and motion stability

By prioritizing rated torque during motor selection, engineers can avoid common performance issues and ensure that the motor delivers reliable output throughout its operational lifespan.

What Is Peak Torque?

Peak torque refers to the maximum amount of torque a motor can produce for a short period of time. This value represents the motor’s short-term overload capability and is typically available only during transient operating conditions such as startup, rapid acceleration, or sudden load changes.

Unlike rated torque, peak torque is not intended for continuous operation. It is limited by thermal and electrical constraints, as sustaining peak torque for extended durations would quickly cause excessive heat buildup and potential damage to the motor.

How Peak Torque Is Achieved

Peak torque is generated by temporarily increasing the motor current beyond its continuous operating level. This surge in current allows the motor to produce higher torque output, but it also results in significantly higher heat generation within the windings.

Because of this, peak torque is strictly time-limited. Manufacturers usually specify the allowable duration, often measured in seconds, during which peak torque can be safely applied before the motor must return to its rated operating range.

Typical Applications of Peak Torque

Peak torque plays an important role in applications that require short bursts of high force. Common use cases include:

- Motor startup from rest

- Rapid acceleration or deceleration

- Overcoming momentary load spikes

- Compensating for brief mechanical resistance

In motion control systems, peak torque helps ensure responsive performance without sacrificing long-term reliability when used correctly.

Limitations and Risks of Relying on Peak Torque

While peak torque can enhance short-term performance, relying on it as a primary performance metric can be misleading. Continuous operation near peak torque levels increases the risk of overheating, reduced efficiency, and shortened motor lifespan.

In addition, peak torque does not accurately reflect how a motor will behave under sustained load. Systems designed solely around peak torque values may suffer from thermal instability, inconsistent motion, or unexpected downtime.

Peak Torque in Linear Motor Systems

In linear motor applications, peak torque is often expressed as peak force. This peak force capability supports rapid positioning, quick response times, and dynamic motion profiles. However, just like rotary systems, it must be used within defined time limits.

For high-precision linear motion systems, peak force should complement, the continuous force rating. A balanced understanding of both specifications is essential to achieving optimal performance and long-term system reliability.

Rated Torque vs Peak Torque: Key Differences

Understanding the difference between rated torque and peak torque is essential for evaluating real motor performance. While both specifications describe torque capability, they serve entirely different purposes and should be interpreted in different operating contexts. The following comparisons highlight how these two values impact performance, reliability, and long-term system behavior.

1. Continuous Operation vs Short-Term Capability

The most fundamental difference between rated torque and peak torque lies in how long each can be sustained. Rated torque defines the level of torque a motor can deliver continuously without overheating. It represents stable, long-duration performance and is the foundation of reliable motor operation.

Peak torque, by contrast, is designed for brief moments only. It enables the motor to handle short bursts of high demand such as acceleration or sudden load changes, but cannot be maintained without risking thermal damage. Understanding this distinction helps engineers avoid designing systems that unintentionally operate beyond safe limits.

In practice, rated torque determines how the motor performs most of the time, while peak torque addresses only occasional demands.

2. Thermal Limits and Heat Management

Rated torque is directly linked to thermal equilibrium. At this operating point, heat generated within the motor is effectively dissipated, allowing temperatures to remain within safe limits during continuous use. This balance is critical for preserving insulation integrity and overall motor health.

Peak torque pushes the motor beyond its thermal comfort zone. The increased current required to produce peak torque generates significantly more heat, which can only be tolerated for a short duration. If peak torque is applied too frequently or for too long, thermal stress accumulates and accelerates component degradation.

From a thermal perspective, rated torque supports longevity, while peak torque must be carefully controlled.

3. Reliability and Motor Lifespan

When evaluating long-term system reliability, rated torque is the more meaningful specification. Motors operating within their rated torque range experience less thermal cycling and mechanical stress, resulting in longer service life and more predictable performance.

Peak torque, although valuable, introduces higher electrical and mechanical loads. Repeated reliance on peak torque can shorten motor lifespan, increase maintenance requirements, and reduce system uptime. For industrial and automation environments, this trade-off must be clearly understood.

Reliable systems are built around rated torque, not peak torque.

4. Performance Stability and Motion Precision

Rated torque contributes directly to smooth and stable motion. In precision applications, maintaining consistent torque output is essential for accurate positioning, repeatability, and vibration control. This is especially critical in motion control and linear motor systems where even minor fluctuations can affect performance.

Peak torque enhances dynamic response but may introduce instability if used excessively. While it improves acceleration and responsiveness, it does not guarantee smooth operation over time. A well-designed system uses peak torque strategically while relying on rated torque for overall motion quality.

Precision depends on consistency, not maximum output.

5. Real-World Application Relevance

In real-world motor selection, rated torque reflects how the motor will perform under normal operating conditions. It defines the motor’s ability to handle continuous loads, meet production demands, and operate efficiently over extended periods.

Peak torque, on the other hand, should be viewed as a support specification, important, but secondary. It ensures that the motor can handle occasional overloads without failure, not that it should operate at that level continuously.

The best motor choice balances both values, with rated torque as the primary design criterion.

Rated torque and peak torque are not competing specifications, they are complementary. However, confusing one for the other can lead to poor motor selection and unexpected performance issues. By prioritizing rated torque for continuous operation and using peak torque only where necessary, engineers can achieve optimal performance, reliability, and efficiency in both rotary and linear motor systems.

How to Choose the Right Motor Based on Torque Ratings

Choosing the right motor requires more than comparing torque numbers on a datasheet. It involves understanding how torque ratings interact with real operating conditions and system demands. To make an informed decision, engineers should evaluate torque specifications through the following practical considerations:

- Start with continuous load requirements: Determine the torque needed to maintain steady operation under normal working conditions. This value should be safely within the motor’s rated torque to ensure thermal stability and long-term reliability.

- Analyze the duty cycle of the application: Consider how often the motor operates at high load, how long it runs continuously, and how frequently it starts and stops. A demanding duty cycle increases the importance of rated torque over peak torque.

- Use peak torque only for short-term demands: Identify moments such as startup, rapid acceleration, or brief load spikes where additional torque is required. Ensure that peak torque is sufficient for these events, but limited in duration according to manufacturer specifications.

- Account for thermal conditions and cooling: Ambient temperature, airflow, and mounting configuration directly affect how much torque a motor can sustain. A motor operating in a confined or high-temperature environment may require a higher rated torque margin.

- Evaluate precision and motion stability needs: Applications requiring smooth motion, high repeatability, or accurate positioning should prioritize motors with strong rated torque performance to avoid instability caused by frequent torque fluctuations.

- Translate torque correctly for linear motor systems: In linear motors, torque ratings correspond to continuous and peak force. Understanding this conversion is essential to ensure the motor can handle both steady loads and dynamic motion profiles effectively.

By approaching motor selection through torque ratings in this structured way, engineers can avoid over-reliance on peak specifications and focus on sustainable performance. A well-chosen motor balances rated torque for continuous operation with peak torque for dynamic demands, delivering efficiency, precision, and long-term system reliability.

Conclusion

Understanding the difference between rated torque and peak torque is essential for evaluating true motor performance. While peak torque highlights short-term capability, rated torque defines how a motor performs under continuous, real-world operating conditions. Confusing these two specifications can lead to overheating, unstable motion, and reduced system lifespan.

For most industrial and motion control applications, reliable performance is built on rated torque. It determines thermal stability, motion consistency, and long-term efficiency, especially in precision-driven systems such as linear motors. Peak torque remains important, but only when applied strategically and within clearly defined limits.