Torque Motors

From ITG Linear Motor

Torque Motors are direct-drive rotary motors that deliver high torque with smooth, precise performance, ideal for industrial automation and motion control systems. These compact, high torque electric motors are also well-suited for applications where space and accuracy matter, making them a trusted choice in the high torque linear motor category.

High torque output

Smooth & cog-free

Compact hollow shaft

High-resolution encoder

No gearbox needed

Everything about Torque Motors

What is Torque Motors?

A torque motor is a type of high torque electric motor that delivers continuous rotary force without using gearboxes. Known for smooth, cog-free motion and high stability, torque motors are widely used in CNC spindles, rotary tables, and robotic joints offering a compact alternative to traditional high torque linear motor setups.

What are the advantages of direct drive torque motors?

Direct drive torque motors offer multiple advantages compared to conventional motor systems with gear reducers:

Zero backlash for accurate and repeatable motion

High torque output at low speeds

Compact and simplified mechanical structure

Quiet operation and low maintenance due to fewer moving parts

Hollow shaft design allows internal cable or fluid routing

These features make torque motors especially suitable for high-precision automation systems, such as semiconductor tools, robotics, and CNC rotary tables.

Hollow shaft torque motor applications

Hollow shaft torque motors are designed with a central opening that allows components such as signal cables, pneumatic tubes, liquid cooling lines, or sensors to pass directly through the motor shaft.

Typical applications include:

Robotic joints, where internal cable routing increases flexibility and reduces external clutter.

CNC rotary tables, where power and signal lines must rotate seamlessly with the table.

Semiconductor and cleanroom equipment, which require compact, low-contamination solutions.

Optical inspection systems and other machines where space-saving, precise integration is essential.

ITG’s TMXSL models are particularly optimized for these hollow shaft applications, offering a combination of thin structure and high-performance torque.

How does Torque Motor work?

Torque motors use a direct-drive mechanism where electromagnetic force generated by the stator rotates the rotor without mechanical transmission. This design ensures zero backlash and minimal vibration. With built-in encoders, these high torque electric motors offer precise control, making them ideal for high-performance automation and positioning systems.

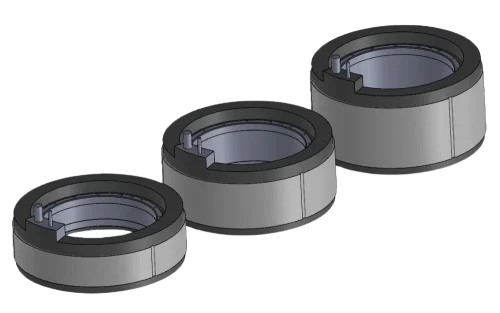

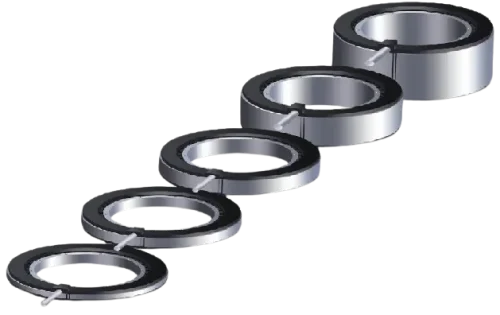

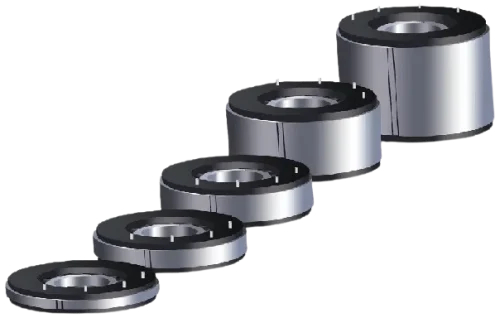

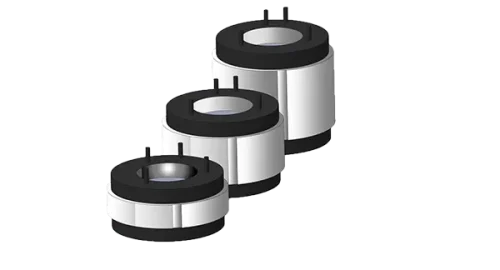

Difference between TM and TMXSL torque motor series

The TM series includes standard-size torque motors, ranging from 65mm to 160mm in outer diameter. These motors are designed for general industrial applications where space constraints are not critical.

In contrast, the TMXSL series features ultra-thin torque motors engineered specifically for equipment with limited installation space. Despite their thinner form, TMXSL motors still deliver high torque and stable performance.

Both series support hollow shaft configurations, direct drive operation, and high-precision motion control. The main difference lies in the form factor: TMXSL models are slimmer and lighter, making them ideal for space-sensitive applications such as semiconductor equipment, robotic joints, or cleanroom rotary systems.

How to select a torque motor for automation?

When selecting a torque motor for automation, several factors must be considered:

Required torque output (both continuous and peak)

Operating speed range

Space and form factor constraints

Hollow shaft requirements for cable or fluid routing

Desired level of positioning accuracy and system stiffness

ITG’s TM and TMXSL torque motor series provide options from 65mm to 160mm in diameter, allowing engineers to choose the right model based on torque demands, installation space, and application-specific needs. The TMXSL series is especially well-suited for compact and precision-critical environments.

Torque Motors Series

-

TM160 Series

Read more -

TM210 Series

Read more -

TM290 Series

Read more -

TMXSL133 Series

Read more -

TMXSL160 Series

Read more -

TMXSL105 Series

Read more -

TMXSL78 Series

Read more -

TMXSL65 Series

Read more -

TM133 Series

Read more -

TM105 Series

Read more -

TM78 Series

Read more -

TM65 Series

Read more -

TM40 Series

Read more

What is Torque Motors used for?

Related Articles

Choosing the right high torque servo motor can make or break the performance of your automation system. From robotic arms that require precise, powerful movements to heavy-duty packaging lines that

Selecting the right high torque servo motor is more than just picking a component, it’s about unlocking the full potential of your machinery. Traditional servo motors with gearboxes often fall

High torque electric motors are revolutionizing the way industries approach power, precision, and performance. Unlike conventional motors, they are engineered to deliver superior rotational force while maintaining efficiency and control

What is a hollow shaft torque motor?

A hollow shaft torque motor is a direct drive motor designed with a central opening that allows cables, fluids, or air to pass through the center of the shaft. This design is ideal for applications like robotic joints, rotary tables, and cleanroom systems where internal routing and compact integration are essential. ITG offers multiple hollow shaft models across both TM and TMXSL series.

Who manufactures ultra-thin torque motors?

Several manufacturers offer ultra-thin torque motors, but ITG is among the few that specialize in compact, high-torque, low-profile designs. The TMXSL series from ITG features outer diameters ranging from 65mm to 160mm, engineered for space-limited environments without compromising torque performance or stability.

TM133 vs TMXSL133: Which motor is better?

TM133 and TMXSL133 are both 133mm outer diameter torque motors, but they differ in form factor and application. TM133 has a standard structure suitable for general automation, while TMXSL133 is thinner and optimized for compact systems. Choose TM133 for stable installations with more space; choose TMXSL133 for cleanrooms or equipment requiring low-profile integration.

What are TMXSL torque motors used for?

TMXSL torque motors are used in applications that require high torque, precise motion, and limited installation space. Typical uses include semiconductor equipment, robotic joints, vacuum environments, cleanroom tools, and compact rotary tables. Their ultra-thin structure and hollow shaft design make them ideal for modern automation systems with strict dimensional constraints.

Room 401, Building 7#, No.26, Qinghua Road, Phase ll of Science & Technology Innovation Park, Xushuguan Town, SND, Suzhou

itgmotor_sz@126.com

+86 139.140.332.75