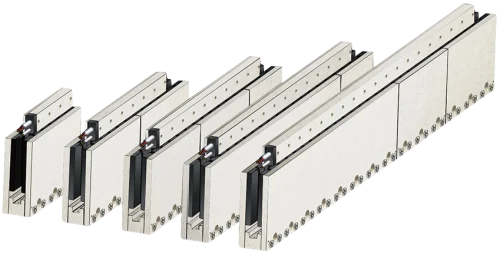

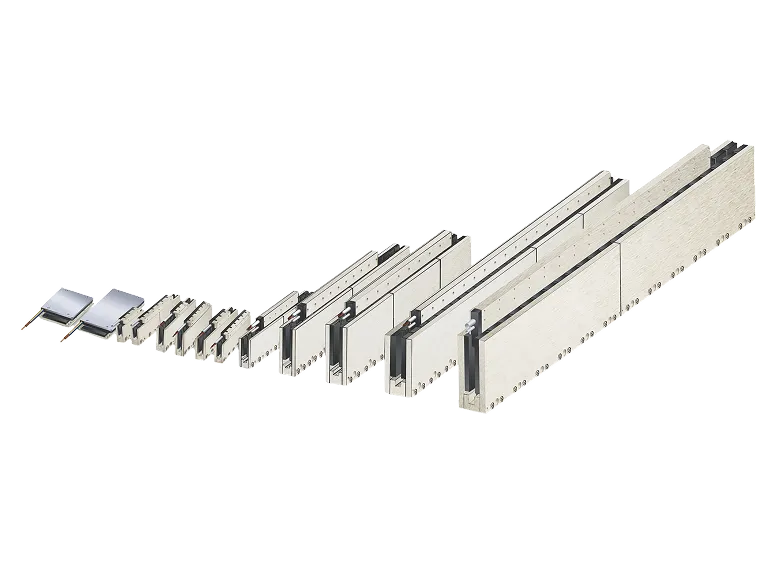

Ironless Linear Motors – Zero Cogging, Clean Precision From ITG Linear Motor

From ITG Linear Motor

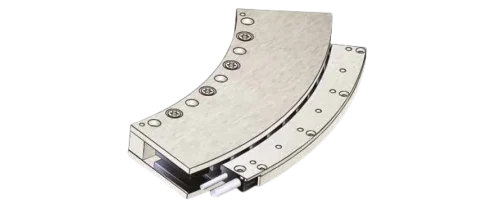

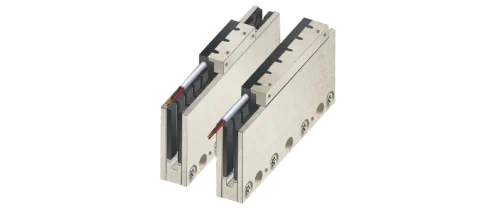

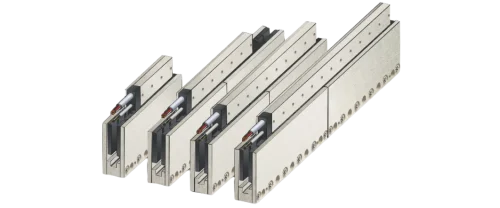

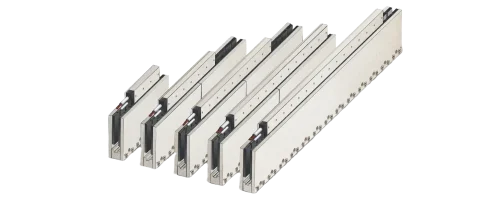

Experience ultra-smooth and high precision motion with ITG’s ironless linear motor series, engineered for accuracy-critical automation. With zero cogging and exceptional dynamic response, our motors are ideal for semiconductor, medical, and advanced automation applications.

No cogging

High acceleration

Efficient thermal management

Precision automation

Compact & modular

Everything about Ironless Linear Motor

Cogging-Free, Ultra-Smooth Motion

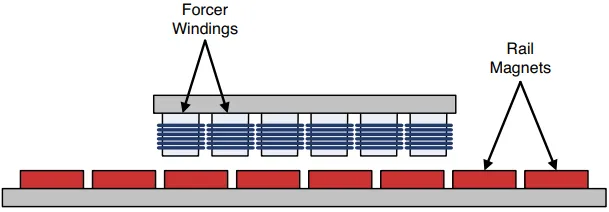

The ironless linear motor eliminates cogging completely thanks to its coreless coil design. This enables exceptionally smooth and vibration-free motion, making it ideal for applications requiring constant velocity and high-precision scanning such as wafer inspection, laser processing, and optical alignment.

High Acceleration and Fast Dynamic Response

With minimal moving mass, the ironless linear motor delivers rapid acceleration and short settling times perfect for dynamic, high-speed applications. It supports fast start-stop cycles with excellent servo responsiveness, enabling superior throughput in robotics, pick-and-place systems, and precision automation.

Sub-Micron Positioning Accuracy

Engineered for accuracy-critical environments, the ironless linear motor achieves sub-micron resolution with zero magnetic drag. When paired with high-resolution encoders, it ensures exceptional linearity and repeatability for demanding applications like metrology, semiconductor inspection, and nanotechnology.

Versatile for High-Precision Applications

From semiconductor tools to medical equipment and advanced automation, ironless linear motors are optimized for industries that demand ultra-smooth, high-accuracy motion. Their compact, clean, and cogging-free design supports a wide range of precision systems operating in cleanrooms or vibration-sensitive environments.

What is Ironless Linear Motor used for?

Related Articles

In industrial motion systems, performance is often judged by speed, torque, and precision, but one critical factor is frequently overlooked: shaft design. The choice between a solid shaft motor and

In modern industrial automation, motion is no longer limited to straight lines or simple rotations. As production systems demand higher speed, greater flexibility, and more compact machine layouts, curved linear

Precision, speed, and motion stability define the performance limits of modern automation systems. As industrial applications demand smoother trajectories, higher positioning accuracy, and shorter cycle times, conventional rotary-driven mechanisms increasingly

Room 401, Building 7#, No.26, Qinghua Road, Phase ll of Science & Technology Innovation Park, Xushuguan Town, SND, Suzhou

itgmotor_sz@126.com

+86 139.140.332.75