Custom Linear Electric Motor

From ITG Linear Motor

ITG specializes in designing high-precision linear motors tailored to unique industrial needs offering engineering flexibility, seamless integration, and reliable performance in every custom electric motor we deliver.

No cogging

No cogging

No cogging

No cogging

No cogging

Design Custom Linear Motor Solution

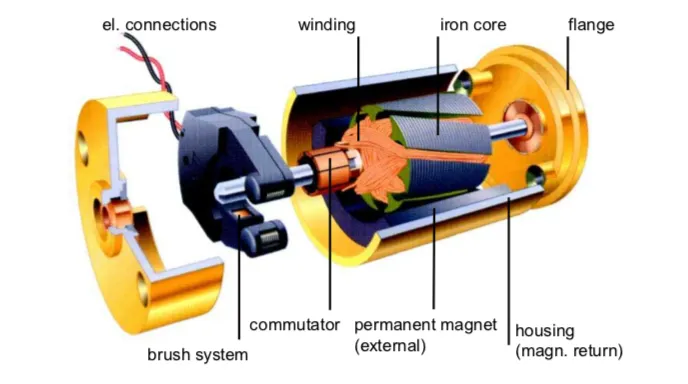

What is a custom linear motor?

A custom linear motor is a type of direct-drive system designed to meet specific mechanical or environmental requirements that standard motors cannot fulfill. These motors are often co-engineered to deliver optimized performance, compact design, and seamless integration.

Key characteristics:

Tailored force, speed, and stroke to meet precise application needs

Form factors designed to fit unique spatial constraints

Support for cleanroom, vacuum, or high-temperature conditions

Compatibility with custom encoders, sensors, and control systems

Custom linear motors help OEMs and integrators reduce system complexity while improving reliability and precision.

Applications of custom linear motors

Customized linear motors are ideal for advanced applications where off-the-shelf solutions are insufficient. They are commonly used in:

Semiconductor equipment: wafer handling, alignment stages, lithography

Digital printing and packaging systems: high-speed, vibration-free movement

Robotic systems: pick-and-place, SCARA arms, collaborative robots

Laser processing machines: cutting, engraving, welding

Medical imaging and lab automation devices

Scientific instruments requiring smooth, cog-free motion

These motors are essential for applications where compact integration and performance consistency are non-negotiable.

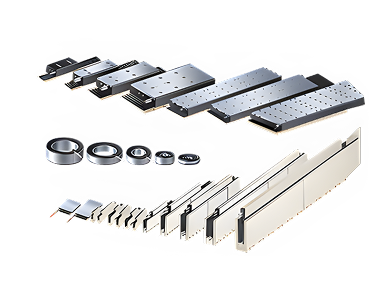

Customization options available at ITG

ITG offers extensive customization services for linear motors to align with specific industrial needs.

Available options include:

Force configuration: from low thrust to high acceleration profiles

Stroke length: short travel to long-range applications

Structure: compact, flat, or hollow-shaft formats

Feedback systems: built-in encoders, Hall sensors, or client-specified devices

Materials: stainless steel, anti-corrosive alloys, vacuum-compatible materials

Environmental protection: cleanroom compliance, sealed housing options

Mounting and wiring: custom mechanical interfaces and cable layouts

All custom motors are engineered to optimize performance, integration, and durability.

When should you consider custom over standard

You should consider custom linear motors when standard models create limitations or introduce complexity in your system.

Typical scenarios:

Space or mounting constraints in machine design

Required speed, force, or precision exceeds standard performance

Application involves vacuum, humidity, or contamination-sensitive environments

Unique integration needs with existing motion controllers or sensors

Project requires high-volume production with streamlined installation

Custom motors reduce the total cost of ownership and improve long-term operational efficiency.

ITG’s custom linear motor design process

ITG follows a structured and transparent development workflow to deliver purpose-built linear motors.

Process overview:

Application requirement gathering with client engineering teams

Technical feasibility assessment using simulation and modeling

Collaborative design: CAD files, FEA analysis, and functional specs

Prototype build and real-world validation

Design refinement based on testing feedback

Final production with full documentation and QA procedures

This process ensures functional accuracy, performance reliability, and seamless integration with your system.

Industries that benefit most from custom linear motors

Custom linear motors from ITG are designed to serve industries with high demands for precision, cleanliness, and reliability.

Key industries:

Semiconductor manufacturing and inspection systems

Flat panel and OLED display production lines

Robotics and industrial automation

Medical imaging and diagnostic platforms

Laser cutting, engraving, and AOI machinery

Scientific research and laboratory instrumentation

Aerospace motion simulation and positioning systems

These industries rely on tailored motion systems to meet exacting performance and integration standards.

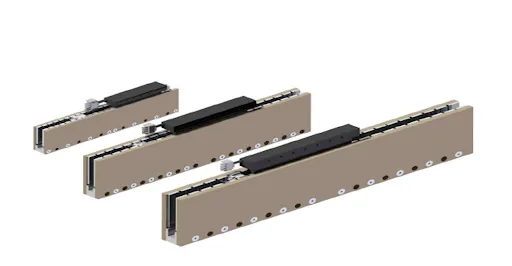

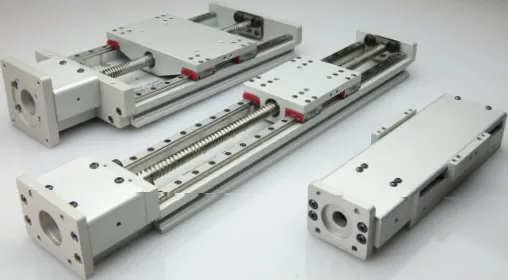

Custom Linear Motor Series

What is Custom Linear Motor used for?

Related Articles

In today’s rapidly evolving industrial landscape, motion control systems play a critical role in determining the efficiency, precision, and reliability of modern machines. As industries demand higher performance with lower

In today’s precision-driven industries, linear motors have become the backbone of automation, powering everything from semiconductor assembly lines to high-speed inspection systems. Yet, when it comes to choosing the right

Imagine a world where machines move with human-like precision, arms that glide smoothly, platforms that shift effortlessly, and systems that react in milliseconds. At the heart of these movements lies

Room 401, Building 7#, No.26, Qinghua Road, Phase ll of Science & Technology Innovation Park, Xushuguan Town, SND, Suzhou

itgmotor_sz@126.com

+86 139.140.332.75