In today’s precision-driven industries, linear motors have become the backbone of automation, powering everything from semiconductor assembly lines to high-speed inspection systems. Yet, when it comes to choosing the right solution, one question consistently arises: why do linear motor prices vary so widely?

The truth is, behind every price tag lies a combination of engineering complexity, performance demands, and material precision. Understanding these factors is essential not only to manage your investment effectively but also to ensure your machine delivers the efficiency and reliability your operation requires.

In this article, we’ll break down the key elements that affect linear motor cost, helping you make informed, value-driven decisions, whether you’re sourcing for a new project or optimizing your existing automation system.

Why Does Linear Motor Price Matter?

When evaluating motion systems for industrial or automation projects, the price of a linear motor is more than just a purchase figure, it represents the foundation of your system’s performance, reliability, and long-term operating costs.

A linear motor directly influences how efficiently your machine converts electrical energy into motion. The right investment can lead to higher speed, smoother movement, and reduced mechanical wear. Conversely, choosing a low-cost motor without considering performance requirements may result in inconsistent positioning, overheating, or frequent maintenance, all of which increase total expenses over time.

In industries such as semiconductor manufacturing, robotics, medical equipment, and precision measurement, where even microns of error can compromise product quality, the price of the motor often reflects its engineering sophistication. Factors such as coil design, magnetic materials, and integrated feedback systems all contribute to achieving higher precision and naturally, a higher cost.

However, that doesn’t mean expensive always equals better. The key is to balance performance and cost, selecting a linear motor that meets your operational needs without overinvesting in unnecessary specifications. By understanding what drives the price, buyers can make smarter decisions that maximize value, productivity, and system lifespan.

At ITG Motor, our mission is to help customers find this balance, offering cost-effective linear motion solutions that deliver high precision and durability while maintaining competitive pricing across all performance levels.

Key Factors That Affect Linear Motor Price

The price of a linear motor is influenced by a variety of technical and market-related factors. Understanding these helps engineers and procurement teams make informed decisions when selecting the right motor for their application.

1. Type of Linear Motor

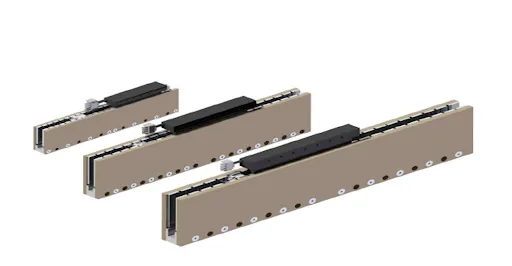

There are several types of linear motors each designed for different performance requirements and budgets.

- Iron-core linear motors are generally more affordable and deliver high thrust, making them suitable for heavy-duty industrial applications. However, they generate more heat and may experience cogging effects that reduce motion smoothness.

- Ironless linear motors, on the other hand, are built for ultra-smooth motion and high precision. They are ideal for semiconductor and inspection equipment but come at a higher cost due to their complex coil and magnet design.

- Voice coil motors (VCMs) occupy a unique segment, offering short stroke and rapid acceleration. Their price varies depending on the stroke length and peak force requirements.

In short, the motor type determines both performance capability and price level, a critical starting point in the cost analysis.

2. Force, Speed, and Stroke Requirements

The performance specifications of a linear motor, including continuous force, peak force, maximum speed, and stroke length have a direct impact on price.

Higher force and speed demand stronger magnets, larger coils, and enhanced cooling, which increase material and manufacturing costs. Similarly, a longer stroke requires extended magnetic tracks and reinforced mechanical design, further driving up expenses.

When defining your requirements, it’s important to select the optimal combination of thrust and stroke that meets operational needs without overpaying for unused performance.

3. Precision and Feedback Systems

For applications requiring micron-level accuracy, linear motors often integrate advanced feedback systems such as optical encoders or position sensors. These systems ensure precise positioning and repeatability essential for robotics, semiconductor manufacturing, or high-end automation.

However, these integrated systems add cost. The tighter the tolerance and the higher the resolution, the more sophisticated (and expensive) the encoder setup becomes.

In other words, the level of precision you need directly influences the total motor price.

4. Cooling and Thermal Management

Linear motors generate heat during continuous operation. Depending on power density and duty cycle, some motors require forced air or liquid cooling systems to maintain optimal performance.

While air-cooled designs are more cost-effective, water-cooled linear motors provide better thermal stability and sustained thrust output but at a higher cost.

When comparing quotations, it’s essential to factor in the thermal management system, as it can significantly affect both the upfront price and long-term reliability.

5. Customization and Design Complexity

Standard linear motors are usually more affordable and readily available. But when your project demands a customized solution such as a special mounting interface, compact form factor, vacuum compatibility, or unique travel range, the design and engineering process become more complex.

Customization involves additional R&D, tooling, and testing, all of which add to the final price. Nevertheless, for high-performance industries, a custom-built motor often provides superior efficiency and reliability, justifying the extra investment.

6. Brand, Quality, and Country of Origin

Not all linear motors are created equal. Brand reputation, quality assurance, and manufacturing standards play a major role in pricing.

Premium brands from Japan, Germany, or the U.S. often cost more due to strict quality control, high-grade materials, and advanced engineering. In contrast, manufacturers like ITG Motor deliver comparable precision and durability at a more competitive price, thanks to efficient production and optimized supply chains.

Choosing a reputable supplier ensures long-term performance stability and reliable after-sales support, reducing the total cost of ownership.

7. Additional Components and Accessories

Finally, don’t overlook supporting components such as linear guides, amplifiers, cables, and motion controllers. While these are not part of the motor itself, they contribute to the total system cost and should be included when evaluating the overall budget.

A well-integrated system from a single supplier, like ITG Motor, can help minimize compatibility issues and optimize performance, often at a lower total cost than sourcing components separately.

The cost of a linear motor is shaped by a mix of engineering requirements, performance specifications, and manufacturing quality. By understanding each of these factors, buyers can evaluate quotations more accurately and select the best-performing solution for their budget and application.

Typical Price Ranges for Linear Motors

Linear motor prices can vary dramatically depending on their specifications, design, and intended application. In general, most linear motors fall into three broad pricing categories that reflect performance level, build quality, and customization needs.

At the entry level, you’ll find compact linear actuators and iron-core linear motors designed for general-purpose automation tasks. These models typically offer modest thrust force, short stroke lengths, and standard precision levels. Their prices usually range from around $300 to $800, making them suitable for cost-sensitive projects where ultra-high accuracy isn’t a priority.

The mid-range segment includes more powerful models capable of delivering higher thrust, longer strokes, and smoother motion. These motors often feature integrated feedback systems, such as encoders, and improved thermal management to handle continuous operation. Prices in this range commonly fall between $800 and $3,000 or more, depending on configuration and brand. For many industrial users, this segment provides the best balance between performance and cost.

At the high end, linear motors used in precision manufacturing, semiconductor processing, or high-speed robotics can reach $3,000 to $10,000 or higher. These units are engineered for exceptional accuracy, minimal cogging, and long-term reliability under demanding conditions. Some high-end systems also include custom-designed coils, vacuum-compatible housings, or water-cooling systems, all of which increase the overall cost.

It’s also important to consider that the motor itself represents only part of the total investment. Supporting components such as linear guides, amplifiers, and controllers can add significantly to the total system cost.

Ultimately, the right linear motor is not necessarily the most expensive one, but the one that delivers the best performance-to-price ratio for your specific application. By understanding these general price ranges, engineers and buyers can better plan their budgets, compare quotations accurately, and select a motion solution that maximizes both efficiency and long-term value.

How to Get the Best Value When Buying a Linear Motor

Getting the best value when purchasing a linear motor isn’t about finding the cheapest option — it’s about choosing a solution that balances performance, reliability, and total lifetime cost. The right decision can improve system efficiency, reduce maintenance, and maximize ROI.

To ensure you get the most out of your investment, consider the following points:

- Clearly define your performance needs: Identify the exact requirements of your application, including thrust, stroke length, speed, and accuracy. A precise specification helps avoid paying for unnecessary power or ending up with an underperforming system.

- Focus on value, not just price: A higher upfront cost often translates into better materials, longer lifespan, and improved energy efficiency. Evaluate how much performance you gain per dollar spent rather than comparing prices alone.

- Look at the total system cost: Beyond the motor itself, consider the cost of drivers, controllers, and mounting systems. Sourcing compatible components from the same supplier can lower integration costs and ensure smooth operation.

- Request detailed quotations: Always ask for a transparent cost breakdown. Different suppliers may include different accessories or customization options and understanding what’s included helps you compare offers fairly.

- Prioritize quality and technical support: A low-cost motor with poor durability or limited support can result in downtime and lost productivity. Choose a manufacturer that offers strong after-sales service, warranty, and engineering guidance.

- Work with an experienced manufacturer: Partnering with a supplier who understands your industry ensures tailored solutions and better cost efficiency. At ITG Motor, every linear motion product is designed with precision engineering and expert consultation, helping clients achieve optimal performance at the best possible value.

Ultimately, getting the best value means choosing a motor that delivers long-term reliability, strong performance, and full technical backing. By looking beyond the price tag and focusing on total value, you can make a smart, sustainable investment for your business.

Conclusion

Understanding what drives linear motor prices and how they compare to cheap electric motors is the key to making smarter, more cost-effective purchasing decisions. From precision requirements and material quality to customization and supplier expertise, every factor contributes to how much value your investment truly delivers.

While it may be tempting to focus on price alone, the real goal is achieving the best performance-to-cost ratio, a balance that ensures long-term efficiency, durability, and return on investment. Whether you’re designing high-speed automation equipment or precision positioning systems, choosing the right linear motor can make all the difference.

At ITG Motor, we combine advanced engineering, quality manufacturing, and competitive pricing to deliver linear motion solutions that truly empower innovation. Our experts are ready to help you find the perfect motor that meets your performance goals and budget needs, ensuring every move your system makes is precise, efficient, and built to last.