In the world of modern automation, motion is the invisible force that powers precision, speed, and innovation. Every movement, whether a robotic arm placing a microchip or a conveyor transporting products, relies on one of two fundamental motion types: linear or rotary. While both serve critical roles in industrial design, they operate on entirely different principles, influencing efficiency, accuracy, and performance in unique ways. Understanding the key differences between linear and rotary motion isn’t just technical knowledge, it’s the foundation for designing smarter, more reliable, and future-ready automation systems.

Understanding about Linear Motion

Linear motion refers to movement that occurs along a straight path, forward and backward in a single direction. Unlike rotary motion, which revolves around an axis, linear motion travels in a direct line, making it ideal for applications that require high precision and controlled displacement.

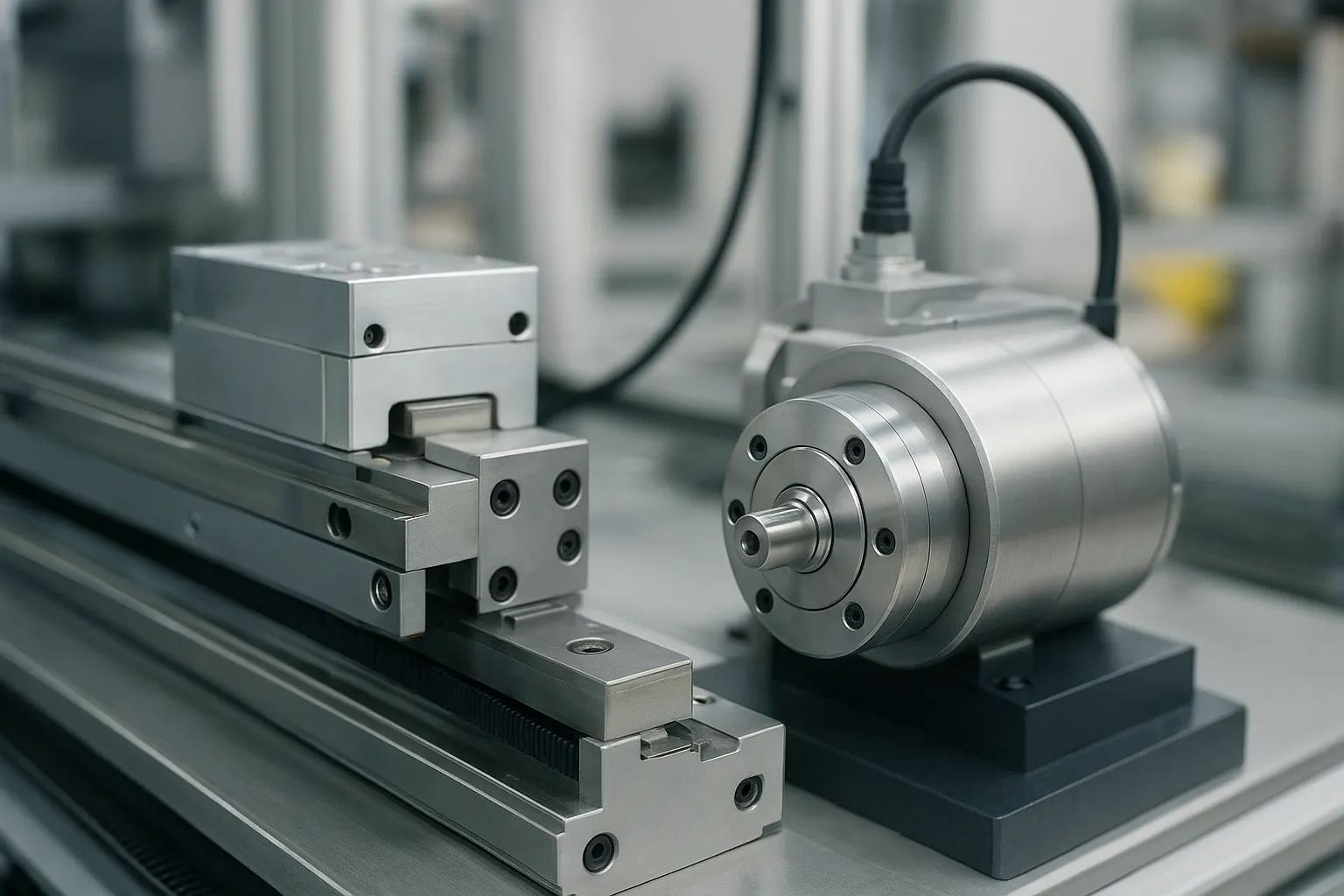

At its core, a linear motion system converts energy into straight-line movement. This can be achieved through various mechanisms such as linear motors, actuators, ball screws, or belt drives. However, with the rise of direct-drive linear motors, industries are moving toward solutions that eliminate mechanical conversions, offering greater accuracy, smoother operation, and reduced wear.

Key components of a typical linear motion setup include:

- Linear motor or actuator – generates and controls the thrust.

- Guide or rail system – ensures smooth and stable travel.

- Bearing assembly – minimizes friction and supports the load.

- Position sensors or encoders – provide real-time feedback for precision control.

In industrial environments, linear motion enables machines to position, move, and assemble parts with exceptional accuracy, essential in robotics, CNC machining, semiconductor production, and automated inspection systems. Its efficiency and repeatability make it a cornerstone of next-generation automation and smart manufacturing.

What Is Rotary Motion?

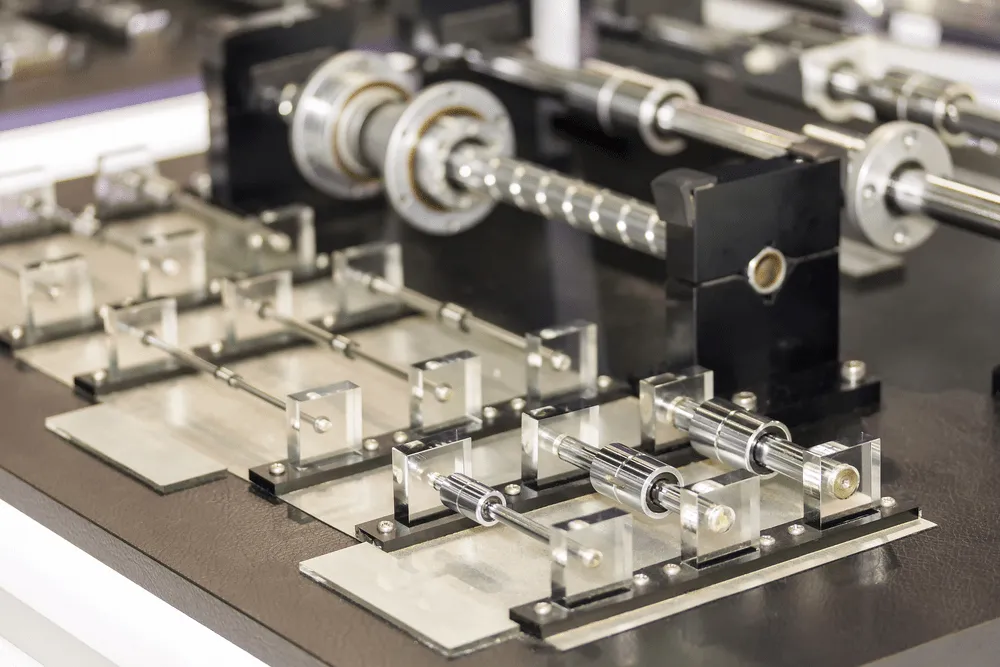

Rotary motion refers to movement that occurs around a central axis or pivot point. Instead of traveling in a straight line like linear motion, rotary motion produces continuous or oscillating circular movement, generating torque rather than direct thrust. This type of motion is fundamental to countless mechanical systems, from the rotation of a motor shaft to the spinning of a turbine blade.

In a rotary system, energy is transformed into rotational movement through components such as rotary motors, shafts, bearings, gears, or pulleys. The applied torque causes the system to spin, transmitting mechanical power efficiently across a wide range of applications. Rotary motion is particularly effective when the goal is sustained rotation or power transfer, rather than precise linear positioning.

Typical components of a rotary motion setup include:

- Rotary motor – generates torque to drive the system.

- Shaft – transfers rotational force to connected parts.

- Bearings – reduce friction and support smooth rotation.

- Gears or pulleys – adjust speed, torque, and direction.

Rotary motion is at the heart of many everyday machines, pumps, fans, wheels, engines, and conveyor drives all depend on it. Its simplicity, energy efficiency, and durability make it a preferred choice for applications where circular motion is naturally required or when converting energy into continuous mechanical output.

Core Differences Between Linear and Rotary Motion

Although linear and rotary motion are both fundamental to mechanical systems, they differ greatly in how they generate and transmit movement. The most obvious distinction lies in the direction of motion. Linear motion operates along a straight path, forward and backward on a single axis while rotary motion revolves around a central axis, creating circular or angular displacement.

The way force and energy are applied also sets them apart. In linear systems, energy is converted directly into thrust to move an object in a straight line. Rotary systems, on the other hand, produce torque, a twisting force that causes rotation. When designers want to convert rotary motion into linear motion, for example, by using ball screws or belts, additional mechanical components are required, which can introduce friction, backlash, and energy loss.

Another key difference lies in precision and control. Linear motion systems, especially those powered by direct-drive linear motors, provide exceptional accuracy and repeatability because there are no intermediate mechanical transmissions. This makes them ideal for high-precision applications like semiconductor assembly or micro-positioning in robotics. Rotary motion systems, while generally less precise, excel in delivering continuous, high-speed movement and are highly efficient for tasks that rely on sustained rotation.

Maintenance and system complexity also vary. Linear motion systems tend to have fewer moving parts, resulting in less wear and reduced maintenance over time. Rotary systems typically rely on mechanical connections such as gears, shafts, or couplings, which may require periodic lubrication or part replacement. However, their simpler integration into many mechanical designs makes rotary motion a practical and cost-effective choice in numerous industrial settings.

In essence, the decision between linear and rotary motion depends on the nature of the task. When precision, stability, and smooth linear displacement are priorities, linear motion delivers unmatched performance. When efficiency, torque, and rotational energy transfer are the goals, rotary motion remains the more suitable solution.

Advantages of Linear Motion Systems

Linear motion systems are increasingly becoming the backbone of precision engineering and modern automation. Their ability to translate energy directly into smooth, accurate linear displacement offers a level of performance that conventional rotary systems often cannot match. Below are the key advantages that make linear motion indispensable in advanced industries.

1. Direct-Drive Precision Without Mechanical Losses

One of the greatest strengths of linear motion systems is their direct-drive architecture. Unlike rotary systems, which require additional mechanical conversions (such as screws, belts, or gears) to achieve straight-line motion, linear systems generate thrust directly along the travel axis.

This eliminates backlash, mechanical wear, and energy loss typically caused by transmission components. The result is superior positioning accuracy, repeatability, and motion smoothness, making linear motion ideal for applications such as semiconductor manufacturing, laser cutting, or optical inspection, where even micrometer-level errors are unacceptable.

2. High Speed and Acceleration for Dynamic Applications

Linear motors are capable of achieving exceptional acceleration and deceleration rates without compromising stability or control. Since there are no rotating parts or mechanical conversions, inertia is minimized, allowing for rapid response and smooth transitions.

This characteristic is crucial in high-throughput automation systems, such as pick-and-place robots, packaging lines, or CNC machinery, where every millisecond of motion efficiency contributes directly to productivity. In these environments, linear motion systems deliver both the speed of execution and precision of movement that modern manufacturing demands.

3. Low Maintenance and Extended Service Life

With fewer moving parts and no direct contact between the stator and mover, linear motion systems inherently experience less mechanical wear. This design drastically reduces maintenance requirements and extends operational lifespan compared to traditional rotary-based setups.

Because there’s little need for lubrication or periodic part replacement, operators benefit from lower total cost of ownership (TCO) and increased uptime, two critical factors in maintaining continuous industrial productivity.

4. Smooth, Quiet, and Contamination-Free Operation

Linear motors operate with minimal noise and vibration, providing a clean, stable motion profile. The absence of gears and belts means fewer contaminants such as oil or debris are introduced into the work environment.

This makes linear motion systems particularly suitable for cleanroom applications, including medical devices, electronics assembly, and precision optical manufacturing, where even microscopic impurities can compromise quality or yield.

5. Seamless Integration and Customization

Linear motion technology offers exceptional design flexibility. Systems can be customized to fit specific load capacities, stroke lengths, and environmental conditions, whether compact or large-scale. Moreover, modern linear systems are fully compatible with advanced motion controllers, sensors, and feedback loops, enabling synchronized and highly responsive automation setups.

Their modular design simplifies integration into both new and existing industrial platforms, supporting a wide range of industries, from robotics and logistics to aerospace and biomedical manufacturing.

6. The Competitive Edge in Modern Automation

In today’s smart factories and precision-driven industries, efficiency and reliability define competitiveness. Linear motion systems deliver both, offering unmatched accuracy, speed, and repeatability with reduced mechanical complexity.

By adopting linear motion solutions, manufacturers can achieve higher throughput, tighter tolerances, and superior energy efficiency. It’s not just an upgrade, it’s a strategic move toward the future of intelligent, high-performance automation.

Real-World Applications: Choosing the Right Motion Type

In practice, the decision between linear and rotary motion depends largely on the type of movement, precision requirements, and operational environment of the application. Each motion type offers distinct advantages that make it more suitable for specific tasks, and understanding these differences is essential for engineers looking to optimize system performance.

Linear motion systems excel in environments where precise, controlled, and repeatable positioning is essential. They are commonly found in:

- Robotics and automation – for pick-and-place systems, precision assembly, or inspection platforms that require micron-level accuracy.

- CNC machines and laser cutting equipment – where cutting heads or tools must move along exact paths with smooth linear trajectories.

- Semiconductor and electronics manufacturing – where sensitive components demand vibration-free, particle-free motion.

- Medical and laboratory devices – where clean, accurate linear displacement ensures reliable diagnostics or sample handling.

These systems are favored for applications that demand stability, low noise, and high responsiveness, especially in smart manufacturing environments that integrate sensors and AI-driven motion control.

Rotary motion systems, on the other hand, dominate wherever continuous circular movement and torque generation are required. They are indispensable in:

- Pumps, compressors, and fans, where rotational energy drives fluid or air flow.

- Engines and turbines, which rely on rotational force to produce mechanical power.

- Conveyor systems and rotating joints, where repetitive rotation provides smooth material handling and energy transfer.

While rotary motion offers simplicity, cost efficiency, and high-speed operation, linear motion provides unmatched precision and control, qualities that are increasingly critical in industries transitioning toward automation and digital manufacturing. In many cases, modern systems even combine both motion types, using rotary actuators for large-scale movement and linear stages for fine adjustments, achieving the best of both worlds.

Ultimately, the “right” motion type depends on the nature of the task: rotary motion powers systems that need continuous rotation and torque, while linear motion drives the precision, flexibility, and accuracy that define the next generation of industrial innovation.

Conclusion

Both linear and rotary motion are indispensable forces behind modern engineering, each powering machines and innovations in its own way. Rotary motion continues to provide efficiency and simplicity in systems built for continuous rotation and torque generation, while linear motion defines the future of high-precision, intelligent automation.

As industries evolve toward smart manufacturing, digital control, and higher performance standards, the demand for seamless, accurate, and reliable movement has never been greater. Linear motion systems, especially those driven by advanced linear motors, deliver the precision, speed, and durability required to meet these challenges head-on.

At ITG Linear Motor, we believe motion is more than mechanics, it’s the foundation of innovation. By harnessing cutting-edge linear motion technologies, we help businesses transform automation into a competitive advantage, enabling production systems that are not only faster and cleaner but also smarter and more sustainable for the future.