Permanent Magnet Synchronous Motors (PMSMs) have become the gold standard for high-performance motion systems thanks to their exceptional efficiency, torque density, and precise controllability. As industries move toward faster, smarter, and more energy-efficient automation, understanding what truly drives the performance of a PMSM is more important than ever.

From magnetic design and control algorithms to thermal management and torque ripple mitigation, each factor plays a critical role in determining how well a motor can deliver speed, stability, and long-term reliability. In this guide, we break down the key performance factors that engineers and system designers must consider when evaluating or selecting a PMSM for advanced applications, especially in robotics, CNC machinery, electric vehicles, and modern linear motor platforms.

What is a Permanent Magnet Synchronous Motor?

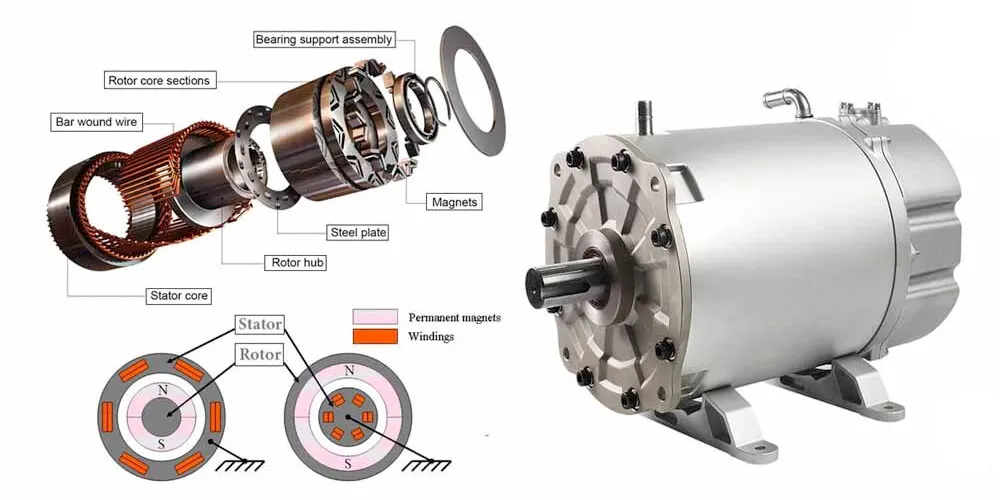

A Permanent Magnet Synchronous Motor (PMSM) is a type of synchronous motor that uses permanent magnets embedded in or attached to the rotor to create a constant magnetic field. Unlike induction motors, which rely on electromagnetic induction to generate rotor currents, PMSMs do not require additional excitation. This design allows PMSMs to deliver higher efficiency, greater torque density, and more precise motion control, making them one of the most advanced motor technologies used in modern automation systems.

At its core, a PMSM operates on the principle of synchronous rotation. This means the rotor rotates at the same speed as the rotating magnetic field generated by the stator. Because there is no slip between the stator field and rotor position, PMSMs can achieve exceptionally accurate speed regulation and smooth torque output, key advantages for applications requiring high precision, such as robotics, CNC machines, semiconductor equipment, and linear motor platforms.

A PMSM consists of two main components:

- Stator: Equipped with three-phase windings that create a rotating magnetic field.

- Rotor: Incorporates high-strength permanent magnets (typically NdFeB or SmCo) arranged to maximize the magnetic flux and minimize losses.

The combination of these elements enables PMSMs to operate with superior dynamic response, low heat generation, and high power efficiency, especially when paired with advanced control strategies such as Field-Oriented Control (FOC) and Maximum Torque Per Amp (MTPA).

Overall, a PMSM represents a significant leap forward in motor technology, offering a compelling blend of efficiency, accuracy, and compact design, characteristics that make it essential for next-generation motion control and high-performance industrial systems.

Key Performance Factors of Permanent Magnet Synchronous Motors

Permanent Magnet Synchronous Motors (PMSMs) are widely adopted across robotics, automation, CNC, electric vehicles, and high-precision linear motion systems because they deliver superior efficiency, torque density, and control fidelity. However, those benefits are not automatic, they result from deliberate design trade-offs, careful materials selection, and sophisticated control strategies.

1. Performance metrics: how we measure a PMSM

Before diving into causes and cures, it’s essential to agree on the metrics that define motor performance. The primary indicators are efficiency (at different load points), continuous and peak torque, torque density (torque per unit volume or mass), speed range and regulation, thermal stability, power density (power per unit volume), torque ripple, and dynamic response (bandwidth, rise time).

Each metric is application-dependent: for a precision linear stage torque ripple and positional jitter may be the top priority; for an EV, high efficiency across a wide speed/torque map matters most. When evaluating a motor, always look at multi-point performance curves (efficiency vs. torque/speed, temperature rise vs. load) rather than a single “rated” number.

2. Magnetic design and rotor topology

The magnetic circuit is the heart of any PMSM. Magnet material (typically NdFeB for high remanence or SmCo for high-temperature stability), magnet grade, magnet geometry, and rotor topology (surface-mounted vs. interior/embedded) govern the flux linkage, back-EMF shape, and intrinsic torque production.

Surface-mounted magnets produce strong sinusoidal back-EMF and are mechanically simple, but interior (IPM) rotors enable reluctance torque and often higher flux-weakening capability for extended speed range. IPM designs also typically offer greater demagnetization resistance and can achieve higher torque density, but at the cost of more complex mechanical design and potentially higher cogging if not optimized.

Magnet sizing influences not only peak torque but also thermal sensitivity, stronger magnets increase torque but are more vulnerable to high temperatures unless proper thermal paths are provided.

3. Stator winding configuration and electromagnetic design

Stator design choices, distributed vs. concentrated windings, slot/pole combinations, and slot shape, significantly influence inductance, harmonic content, copper utilization, and manufacturability. Distributed windings tend to produce smoother torque and lower magnetizing current, while concentrated windings can reduce end-winding length (improving copper utilization and compactness) but increase certain harmonics.

Slot/pole choices affect cogging torque and torque ripple; well-chosen combinations minimize undesirable harmonics in back-EMF and reduce acoustic noise. Additionally, optimizing the air-gap profile and stator tooth geometry lowers iron losses and improves torque ripple suppression. Electromagnetic finite-element analysis (FEA) is indispensable for balancing these trade-offs in modern motor design.

4. Control algorithms and firmware (the “software” of performance)

Hardware matters, but motor controllers largely define usable performance. Field-Oriented Control (FOC) is the de facto standard for PMSMs because it decouples torque and flux control, enabling crisp torque response and high efficiency. Advanced strategies, MTPA (Maximum Torque Per Amp), sensorless observers, adaptive current limiting, and model-predictive control, extract additional performance in terms of torque per amp, efficiency, and dynamic stability.

Careful implementation of field weakening extends high-speed operation but must be balanced with rotor flux limits to avoid demagnetization. Closed-loop position and velocity tuning (PID/lead-lag/advanced state observers) determines tracking error and bandwidth, making controller design as critical as the motor itself for precision applications.

5. Thermal management and heat sources

Heat limits both short-term peak performance and long-term reliability. Losses in PMSMs stem from copper (I²R) losses, core (iron) losses, magnet eddy current and hysteresis losses, and mechanical losses. Design choices (wire gauge, winding layout, lamination grade, magnet segmentation) and system-level cooling (forced air, liquid cooling, heat-sinking to a chassis) determine how effectively generated heat is removed.

Thermal management is especially crucial for high-power-density motors where the cooling surface area is limited. Elevated temperatures reduce magnet strength (risking partial demagnetization) and degrade insulation, both reducing lifetime. Therefore, continuous torque ratings must always be considered alongside allowable temperature rise and cooling strategy.

6. Efficiency and power density trade-offs

PMSMs can achieve very high efficiencies compared to induction machines, principally because permanent magnets provide the field without rotor copper losses. Yet efficiency depends on operating point: partial loads, high speeds (where iron losses dominate), or poor control tuning can reduce net system efficiency.

Increasing power density (more torque or power for a given volume) often requires stronger magnets, tighter thermal management, and advanced winding techniques, improvements that may expose trade-offs, such as higher cogging torque or greater cost. For system designers, the question is rarely “maximize power density” but “optimize power density for the required duty cycle and thermal envelope.”

7. Torque ripple, cogging, and vibration

Torque ripple translates directly into vibration and positional error in precision systems. Primary causes include cogging torque from stator/rotor slot interactions, harmonic content in back-EMF, magnetization non-uniformity, and non-ideal control sampling.

Mitigation strategies span mechanical and electrical domains: skewed slots or magnets, optimized slot/pole combinations, magnet shaping or segmentation, and advanced current-shaping control algorithms. For linear and robotic stages where micron-level accuracy is required, engineering attention to torque ripple reduction is non-negotiable.

8. Reliability, durability, and environmental robustness

Long-term operational reliability hinges on magnet durability (resistance to demagnetization under temperature and mechanical shock), winding insulation class, bearing selection and lubrication, and enclosure/ingress protection. IPM designs with appropriate magnet placement improve demagnetization margins, while superior insulation and conformal coatings protect windings in harsh environments.

Evaluating a motor for real-world conditions means looking beyond datasheet peak numbers: check temperature derating curves, start/stop life cycles, bearing lifetimes under expected loads, and resistance to contaminants (dust, moisture) that can degrade insulation and bearings.

9. Application-specific considerations: linear motion and dynamic loads

When PMSMs are used in linear motor systems or direct-drive stages, the performance factors above are amplified. Torque ripple maps to force ripple and positional jitter; thermal gradients along a long linear stator can create non-uniform performance; and high-acceleration profiles demand both high torque density and excellent controller bandwidth.

Therefore, linear applications often require segmented magnet and winding designs, distributed cooling, and controllers with high sampling rates and advanced observers to preserve precision under dynamic loads.

10. Practical evaluation: testing, datasheets, and benchmarking

Before final selection, perform multi-point testing: static torque, dynamic step response, thermal rise under expected duty cycles, and efficiency mapping across speed and torque. Datasheets should provide torque vs. speed curves, continuous and peak torque ratings, thermal resistance, and recommended controller parameters. Where possible, benchmark candidate motors in a representative test rig to expose interactions between motor, drive, and mechanical load.

Selecting or optimizing a PMSM is an exercise in system thinking: magnetic materials, electromagnetic design, thermal management, and controller strategy interact to determine real-world performance. Prioritize the metrics that matter for your application, whether that’s minimal torque ripple for a precision stage, broad efficiency for a drive train, or compact power density for space-constrained machinery, and evaluate motors using multi-point tests rather than single numbers.

PMSM Performance in Linear Motor Applications

Permanent Magnet Synchronous Motors (PMSMs) play a critical role in modern linear motor systems, especially in industries that require high precision, ultra-smooth motion, and rapid dynamic response. Their unique electromagnetic characteristics unlock performance levels that traditional rotary-to-linear mechanisms cannot match.

- Deliver exceptionally smooth, cog-free motion, minimizing friction and mechanical backlash, a must-have for semiconductor equipment, inspection systems, and precision robotics.

- Provide high force density thanks to strong rotor magnets and optimized stator windings, enabling compact linear stages with powerful thrust output.

- Achieve rapid acceleration and deceleration, allowing systems to handle fast cycle times without compromising accuracy.

- Support micron- or even sub-micron-level positioning, especially when combined with high-resolution encoders and advanced control algorithms such as FOC and model-based observers.

- Offer high efficiency because magnetic excitation comes from permanent magnets rather than induced currents, reducing heat generation and lowering overall energy consumption.

- Maintain consistent force output across the travel range, minimizing ripple and improving repeatability, critical for CNC, laser cutting, and high-speed pick-and-place systems.

- Enable quiet, vibration-free operation by reducing torque ripple and electromagnetic noise compared to other linear drive technologies.

- Integrate easily with direct-drive architectures, eliminating gearboxes, ball screws, and belts, all of which introduce wear and reduce long-term reliability.

- Handle high dynamic loads effectively, thanks to strong magnetic coupling and robust thermal properties that minimize performance degradation during continuous operation.

- Improve system longevity, as fewer mechanical components mean lower friction, reduced maintenance, and extended operational lifespan.

When carefully engineered and paired with high-performance drives, PMSMs empower linear motor platforms with unmatched speed, smoothness, and precision. This combination delivers the reliability and throughput modern automation demands, making PMSMs a cornerstone in next-generation motion control technologies.

Conclusion

Permanent Magnet Synchronous Motors stand at the center of today’s high-performance motion systems, delivering a level of efficiency, accuracy, and dynamic responsiveness that conventional motor technologies struggle to match. From magnetic design and stator architecture to thermal behavior and advanced control algorithms, every performance factor contributes to how a PMSM behaves under real operating conditions, and understanding these factors is essential for making informed engineering decisions.

As industries continue to demand faster cycle times, smoother motion, and increasingly compact system designs, PMSMs offer the ideal balance of power density, precision, and long-term reliability. Their advantages become even more evident in linear motor platforms, where force stability, minimal ripple, and direct-drive simplicity translate into higher throughput and superior positioning capabilities.