In modern motor control systems, precision is not just a performance advantage, it is a fundamental requirement. From industrial automation and robotics to servo drives and linear motors, accurately measuring motor current plays a critical role in controlling torque, ensuring system stability, and protecting equipment from damage.

This is where Hall effect current sensors come into the picture. By enabling non-intrusive, electrically isolated current measurement, these sensors have become a key component in today’s advanced motor control architectures. In this article, we will explore how Hall effect current sensors work in motor control systems, why they are essential for reliable motion control, and how they support high-performance motor applications.

What Is a Hall Effect Current Sensor?

A Hall effect current sensor is a device used to measure electric current by detecting the magnetic field generated around a current-carrying conductor. Instead of making direct electrical contact with the circuit, the sensor relies on the Hall effect phenomenon, allowing it to perform non-intrusive and electrically isolated current measurement, a critical requirement in modern motor control systems.

At its core, a Hall effect current sensor consists of a Hall element placed within a magnetic field created by the flowing current. When current passes through a conductor, it produces a proportional magnetic field. The Hall element detects this magnetic field and generates a voltage output that is directly related to the magnitude of the current. This output signal can then be processed by motor controllers, drives, or control units to monitor and regulate motor performance.

One of the key characteristics that distinguishes Hall effect current sensors from traditional current sensing methods is galvanic isolation. Because the sensor measures the magnetic field rather than the electrical current itself, there is no direct electrical connection between the power circuit and the control electronics. This isolation significantly improves system safety and reduces the risk of damage to sensitive control components, especially in high-power motor applications.

Hall effect current sensors are widely used to measure both AC and DC currents, making them highly versatile for various motor types, including DC motors, AC motors, servo motors, and linear motors. Their ability to provide accurate real-time current feedback makes them an essential building block in torque control, speed regulation, and protection mechanisms within motor control systems.

In summary, a Hall effect current sensor is not just a current measurement device, it is a fundamental sensing solution that enables precise control, enhanced safety, and reliable operation in advanced motor and motion control applications.

The Working Principle of Hall Effect Current Sensors

Understanding how Hall effect current sensors work requires looking beyond the component itself and examining the physical phenomena and signal-processing steps behind it. From the creation of a magnetic field to the delivery of a clean electrical signal for motor controllers, each stage plays a critical role in achieving accurate and reliable current measurement in motor control systems.

1. Magnetic Field Generation Around a Current-Carrying Conductor

Whenever electric current flows through a conductor, it naturally generates a magnetic field around it. The strength of this magnetic field is directly proportional to the magnitude of the current. In motor control systems, this fundamental relationship provides a non-contact method for current measurement.

Hall effect current sensors are designed to position a sensing element close to the conductor or integrate the conductor directly into the sensor structure. By focusing on the magnetic field rather than the electrical path itself, the sensor can measure current without interfering with the power circuit. This approach is particularly valuable in high-current and high-voltage motor applications, where direct electrical measurement may introduce safety risks or additional power losses.

At this stage, the magnetic field serves as the physical link between the flowing current and the sensing mechanism, forming the foundation of Hall-based current measurement.

2. Detection of Magnetic Flux by the Hall Element

At the heart of a Hall effect current sensor lies the Hall element, a semiconductor device that responds to magnetic flux density. When exposed to the magnetic field generated by the current-carrying conductor, charge carriers within the Hall element experience a force that causes them to accumulate on one side of the material.

This accumulation creates a measurable voltage, known as the Hall voltage, across the sensor. The magnitude of this voltage is directly related to the strength of the magnetic field and, therefore, to the current flowing through the conductor. Because the Hall element reacts to magnetic fields rather than electrical current, it maintains complete electrical isolation from the power circuit.

This magnetic-to-electrical conversion is the defining feature of Hall effect current sensors and the key reason they are widely adopted in modern motor control systems.

3. Signal Conditioning and Conversion to a Usable Output

The raw Hall voltage generated by the sensing element is typically small and susceptible to noise. To make this signal usable for motor controllers and drives, it must undergo signal conditioning.

Inside the sensor, amplification, filtering, and temperature compensation circuits process the Hall voltage and convert it into a stable output signal. Depending on the sensor design, this output may be an analog voltage, a current signal, or a digital output compatible with control electronics.

This conditioning stage ensures that the measured current information is accurate, repeatable, and robust, even in electrically noisy industrial environments. As a result, motor control systems can rely on real-time current feedback for precise control and protection functions.

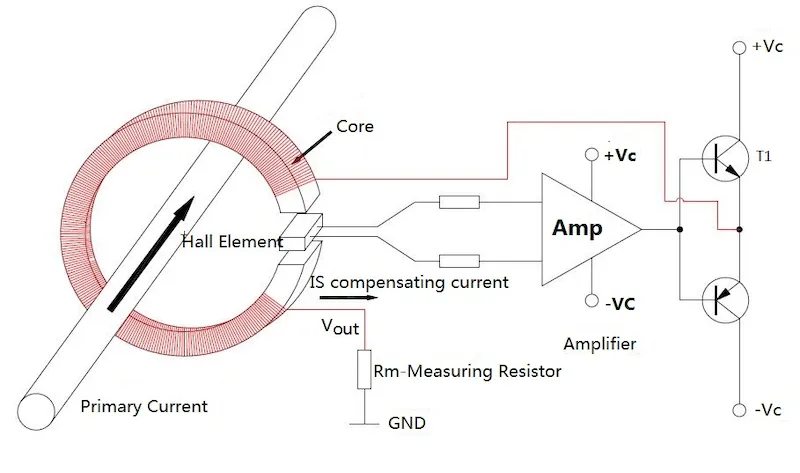

4. Open-Loop vs Closed-Loop Hall Effect Current Sensing

Hall effect current sensors are commonly categorized into open-loop and closed-loop configurations, each with its own working principles and performance characteristics.

Open-loop sensors measure the magnetic field directly using a Hall element, offering a simpler structure, lower cost, and compact size. They are suitable for applications where moderate accuracy and fast response are sufficient.

Closed-loop sensors, on the other hand, use a compensation coil to counteract the magnetic field produced by the measured current. The current required to balance this field becomes the output signal, resulting in higher accuracy, better linearity, and improved temperature stability. This makes closed-loop Hall effect current sensors ideal for high-precision motor control systems such as servo drives and linear motors.

Understanding this distinction is essential when selecting the right sensor for specific motor control requirements.

5. From Current Measurement to Motor Control Feedback

Once the conditioned output signal is generated, it is fed into the motor controller or drive as a real-time representation of motor current. This current feedback plays a central role in torque control, speed regulation, and system protection.

By continuously monitoring current, motor control algorithms can adjust drive signals to maintain stable operation, respond to load changes, and prevent abnormal conditions such as overcurrent or short circuits. In advanced motion systems, especially those using linear motors, precise current feedback directly translates into smoother motion, higher positioning accuracy, and improved system reliability.

At this final stage, the Hall effect current sensor completes its role, not just as a sensing component, but as a critical enabler of intelligent and high-performance motor control.

From magnetic field generation to closed-loop feedback in motor controllers, the working principle of Hall effect current sensors is a carefully coordinated process. By combining non-intrusive measurement, electrical isolation, and accurate signal conversion, these sensors provide the reliable current information that modern motor control systems depend on for precision, safety, and efficiency.

Why Current Measurement Is Essential in Motor Control Systems

In motor control systems, current measurement is far more than a monitoring function, it is the foundation of how motors are controlled, protected, and optimized in real-world applications. Because motor torque is directly proportional to current, accurate current measurement allows control systems to regulate torque precisely, ensuring stable operation under varying load conditions. Without reliable current feedback, even advanced control algorithms would struggle to deliver consistent performance.

Beyond torque control, current measurement plays a vital role in speed and position regulation. In closed-loop motor control systems, current feedback enables controllers to respond instantly to changes in load or motion demand, maintaining smooth acceleration and deceleration. This capability is especially critical in high-precision applications such as servo drives and linear motor systems, where even small current deviations can lead to positioning errors or mechanical stress.

Current sensing is also essential for protecting both the motor and the drive electronics. By continuously monitoring current levels, motor control systems can detect abnormal conditions such as overloads, short circuits, or unexpected torque spikes. When these conditions are identified early, protective mechanisms can be activated to prevent component damage, reduce downtime, and improve overall system reliability. In industrial environments, this proactive protection is a key factor in maintaining long-term operational stability.

In addition, accurate current measurement contributes directly to energy efficiency and thermal management. By analyzing current consumption in real time, motor controllers can optimize drive signals to minimize power losses and reduce heat generation. This not only improves system efficiency but also extends the lifespan of motors and associated components, an increasingly important consideration in modern, high-duty-cycle motion systems.

In essence, current measurement is the invisible feedback loop that enables motor control systems to function intelligently. It connects electrical input to mechanical output, allowing motors to operate with precision, safety, and efficiency across a wide range of industrial applications.

How Hall Effect Current Sensors Are Integrated into Motor Control Systems

In a motor control system, integrating Hall effect current sensors is not a random design choice but a carefully planned step that directly impacts control accuracy, system safety, and overall performance. From sensor placement to signal processing, each integration stage is designed to ensure that current feedback is both reliable and responsive.

- Hall effect current sensors are typically positioned along the motor power path, where they can measure phase current or DC bus current without interrupting the circuit. This non-intrusive placement allows designers to capture accurate current information while maintaining electrical isolation between high-power components and sensitive control electronics.

- In motor drives and servo controllers, the sensor output is routed to the control board, where it becomes a critical input for current control loops. This real-time feedback enables the controller to continuously adjust drive signals, ensuring stable torque production and smooth motor operation even under rapidly changing load conditions.

- For multi-phase motor systems, multiple Hall effect current sensors may be used to monitor individual phase currents. This approach supports advanced control strategies such as field-oriented control (FOC), where precise phase current information is essential for achieving high efficiency and dynamic response.

- Signal conditioning and filtering play a key role in the integration process. The sensor’s output is processed to remove electrical noise and compensate for temperature variations, ensuring that the current data remains accurate in harsh industrial environments commonly found in automation and motion control applications.

- In high-performance systems such as servo drives and linear motor controllers, Hall effect current sensors are tightly integrated into closed-loop architectures. Their fast response time allows controllers to react immediately to current changes, enabling precise motion control, improved positioning accuracy, and enhanced system stability.

As these integration steps come together, Hall effect current sensors transform from standalone components into an essential part of the motor control ecosystem. By delivering accurate, isolated, and real-time current feedback, they enable motor control systems to operate with the precision and reliability required in modern industrial motion applications.

Conclusion

Hall effect current sensors play a critical role in how modern motor control systems achieve precision, safety, and reliability. By enabling non-intrusive and electrically isolated current measurement, these sensors provide the real-time feedback required to control torque, regulate speed, protect equipment, and optimize energy efficiency. From the fundamental physics of magnetic field detection to their integration into closed-loop motor control architectures, Hall effect current sensors have become an indispensable component in today’s industrial motion systems.

As motor control technologies continue to evolve toward higher performance and greater precision, especially in applications such as servo drives and linear motors, the importance of accurate current sensing will only increase. Selecting and integrating the right Hall effect current sensor allows engineers and system designers to build motor control solutions that are not only efficient and responsive, but also robust enough to meet the demands of advanced automation environments.