Precision and speed are the heartbeat of modern automation and direct drive linear motors are setting a new benchmark. By eliminating mechanical friction and boosting responsiveness, these motors empower industries to achieve unprecedented accuracy and operational efficiency. Whether in robotics, high-precision manufacturing, or advanced material handling, direct drive linear motors are not just components, they’re the secret behind smarter, faster, and more reliable production. Discover more with ITG!

Understanding Precision in Motion Systems

Precision is the cornerstone of modern industrial automation. In any motion system, whether it’s robotics, semiconductor manufacturing, or high-speed material handling, precision determines the ability to consistently reach a desired position with minimal error. Even tiny deviations can lead to product defects, wasted materials, and costly downtime.

Why Precision Matters

- Consistent Product Quality: High-precision systems ensure that each component or product meets exact specifications, reducing rejects and rework.

- Operational Reliability: Precision minimizes mechanical stress and wear, leading to longer equipment life and fewer maintenance interruptions.

- Time Efficiency: Accurate motion reduces cycle times by eliminating the need for repeated adjustments or corrections.

Challenges in Achieving Precision

Traditional motion systems, such as rotary motors combined with lead screws or belts, often struggle with:

- Backlash: Slight gaps in mechanical connections cause positional errors.

- Friction and Wear: Mechanical parts generate resistance, reducing repeatability over time.

- Vibration and Overshoot: Inertia and mechanical lag can result in oscillations, especially at high speeds.

These challenges highlight why industries are shifting toward direct drive linear motors, which can overcome many of the limitations of conventional systems. By removing intermediary mechanical components and providing direct, frictionless motion, these motors deliver unmatched precision and repeatability.

How Direct Drive Linear Motors Achieve High Precision?

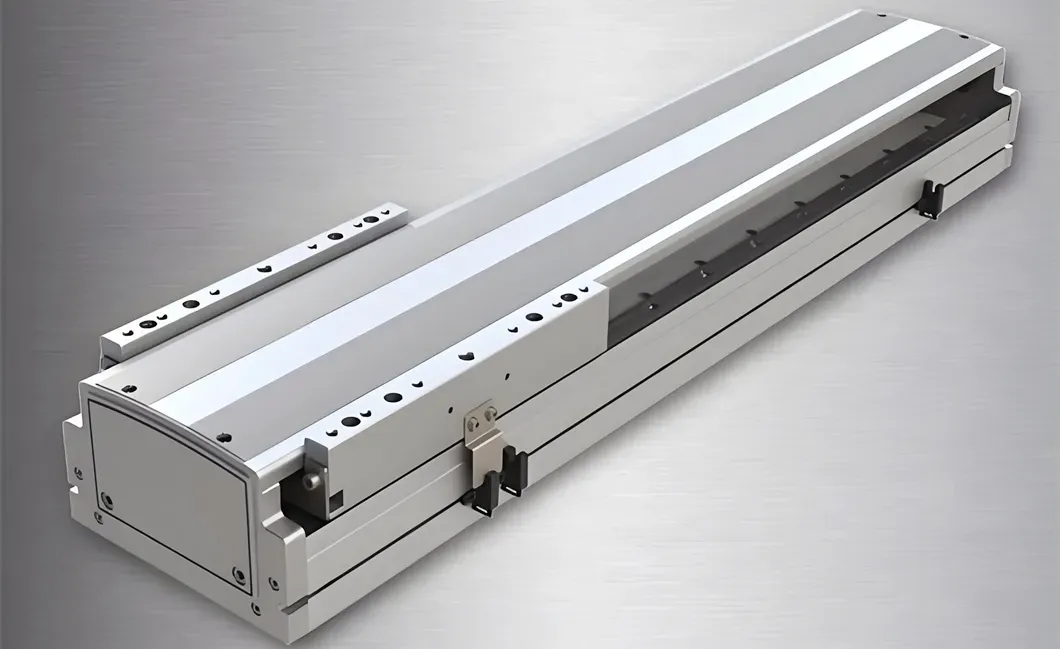

Direct drive linear motors are revolutionizing motion systems by delivering exceptional accuracy and repeatability. Unlike traditional motors that rely on gears, belts, or lead screws, direct drive linear motors eliminate intermediary components, significantly reducing errors and enhancing control. Let’s explore how these motors achieve high precision in industrial applications.

1. Frictionless Design Minimizes Mechanical Errors

One of the key advantages of direct drive linear motors is their frictionless operation. Traditional systems with screws, belts, or gears experience mechanical resistance, which leads to backlash and positional inaccuracies.

- Direct drive motors eliminate these intermediary parts.

- Reduced friction ensures smooth, consistent motion.

- Fewer mechanical components mean lower wear over time, preserving accuracy.

This frictionless design is especially critical in applications requiring sub-micron positioning, such as semiconductor manufacturing or high-precision robotics.

2. Direct Motion Reduces Backlash

Backlash occurs when there’s a gap or looseness in mechanical linkages, causing the output to lag behind the input command.

- In direct drive linear motors, motion is transmitted directly from the motor to the moving part.

- Eliminating gears, pulleys, and screws removes sources of backlash.

- Result: immediate response to control commands, ensuring exact positioning every time.

This capability allows industries to achieve tighter tolerances and higher repeatability in automated processes.

3. High Repeatability Ensures Consistent Performance

Repeatability refers to a system’s ability to return to the same position consistently under the same conditions.

- Direct drive linear motors excel in high-repeatability tasks, often within a few microns.

- Precision sensors and advanced feedback systems maintain exact control.

- This ensures uniform product quality and reduces rework in manufacturing lines.

High repeatability is particularly valuable in pick-and-place systems, CNC machinery, and precision assembly lines.

4. Smooth Motion Control Reduces Vibration and Overshoot

Even the smallest vibrations or overshoot can compromise precision in high-speed operations.

- Direct drive linear motors provide direct electromagnetic force, creating smooth acceleration and deceleration.

- This eliminates the “jerk” effect common in screw or belt-driven systems.

- Controlled motion reduces oscillation, vibration, and overshoot, ensuring accurate end positioning.

Smooth motion also minimizes mechanical stress on equipment, extending its operational lifespan.

5. Integration with Advanced Control Systems

Precision is further enhanced when direct drive linear motors are paired with modern motion controllers and feedback systems:

- Real-time monitoring adjusts the motor response instantly.

- Advanced PID and servo control algorithms maintain exact positioning under varying loads.

- Integration with automation systems ensures consistent performance across complex production lines.

This synergy between hardware and control software maximizes precision and efficiency simultaneously.

By combining frictionless design, direct motion, high repeatability, smooth control, and advanced feedback integration, direct drive linear motors achieve precision levels that traditional motors cannot match. Industries that adopt this technology experience higher product quality, faster cycle times, and lower maintenance costs.

Enhancing Efficiency with Direct Drive Linear Motors

Efficiency is a critical factor in modern industrial automation. Direct drive linear motors not only deliver superior precision but also optimize operational efficiency across various applications. By eliminating unnecessary mechanical components and maximizing energy use, these motors allow businesses to increase throughput while reducing costs.

1. Energy Efficiency Through Direct Drive

Direct drive linear motors convert electrical energy directly into linear motion without intermediary gears or belts, minimizing energy losses.

- No transmission losses: Unlike screw or belt-driven systems, there’s no energy wasted in friction or backlash.

- Lower power consumption: Motors operate efficiently across a range of speeds and loads.

- Sustainable operations: Reduced energy use lowers operational costs and environmental impact.

This energy efficiency is especially important for high-speed and high-volume manufacturing processes.

2. Reduced Maintenance and Downtime

Mechanical components in traditional motors require frequent maintenance due to wear, lubrication needs, and alignment adjustments.

- Fewer moving parts in direct drive systems mean less wear and tear.

- Maintenance-free operation: Motors maintain high performance over longer periods without regular servicing.

- Minimal downtime: Continuous operation improves overall productivity and reduces unexpected production halts.

Industries benefit from higher uptime, more consistent production schedules, and lower maintenance budgets.

3. High-Speed Capabilities for Faster Production

It can accelerate and decelerate rapidly due to their low moving mass and direct electromagnetic drive.

- Faster cycle times: High acceleration enables quick positioning, increasing throughput.

- Precise control at speed: Even at high velocities, accuracy is maintained, preventing errors.

- Optimized automation: Systems can handle more tasks per unit of time without sacrificing quality.

High-speed operation is particularly advantageous in robotics, packaging, and assembly lines.

4. Flexible Integration Enhances Workflow Efficiency

Direct drive linear motors are compact and versatile, allowing seamless integration into complex production systems.

- Adaptable design: Can fit in tight spaces and customized layouts.

- Compatibility with automation software: Enables synchronized multi-axis motion, improving workflow coordination.

- Scalable solutions: Easy to upgrade or expand production lines without major redesigns.

This flexibility helps industries streamline operations and maximize overall system efficiency.

5. Long-Term Cost Efficiency

While initial investment in linear motors can be higher than traditional systems, long-term benefits outweigh costs:

- Reduced energy consumption → lower utility bills.

- Minimal maintenance → reduced service expenses.

- Increased throughput → higher ROI.

Businesses achieve a balance of precision, speed, and cost-effectiveness, making a smart long-term choice.

By combining energy efficiency, low maintenance, high-speed capabilities, flexible integration, and long-term cost savings, direct drive linear motors significantly enhance operational efficiency. They empower industries to produce faster, more accurately, and more sustainably than ever before.

How to Choose the Right Direct Drive Linear Motor

Choosing the right direct drive linear motor is critical to achieving maximum precision, efficiency, and reliability in your operations. Making the wrong choice can lead to costly downtime, reduced accuracy, and increased maintenance needs. Here are the key factors to consider when selecting the ideal motor for your specific application:

- Load Capacity and Stroke Length: Assess the maximum load your system will handle, as well as the total distance the motor must travel. Motors operating near their limits can suffer from reduced accuracy and faster wear. Selecting a motor with appropriate capacity ensures consistent performance under all operating conditions.

- Required Speed and Acceleration: Identify the speed and acceleration your process demands. High-speed operations require motors capable of rapid response without compromising precision. Consider both peak speed and average operating speed to optimize cycle times and throughput.

- Environmental Conditions: Take into account the operating environment, including temperature fluctuations, humidity, dust, or exposure to chemicals. Motors designed for harsh or industrial environments maintain reliable performance over time and reduce unexpected failures.

- Integration with Existing Systems: Ensure that the motor is compatible with your current automation controllers, feedback systems, and software platforms. Smooth integration reduces installation complexity, minimizes downtime, and allows for better synchronization with multi-axis systems.

- Repeatability and Precision Requirements: Determine the precision needed for your application. Tasks like semiconductor fabrication, robotics, or high-precision assembly may demand micron-level repeatability. Choosing a motor that consistently meets these requirements is essential for product quality and process efficiency.

- Maintenance and Service Support: Evaluate the maintenance requirements of the motor and the availability of technical support. Motors with fewer moving parts often require less upkeep, and having accessible service resources ensures faster troubleshooting and minimal operational disruption.

- Long-Term ROI vs. Initial Investment: While high-performance direct drive linear motors may come with a higher upfront cost, their durability, energy efficiency, and reduced downtime often result in significant long-term savings. Consider the total cost of ownership rather than just the purchase price.

- Future Scalability: Anticipate potential growth or changes in production requirements. Selecting a motor that can be easily upgraded or integrated into expanded systems ensures your investment remains valuable as your operations evolve.

By carefully evaluating these factors, businesses can select a direct drive linear motor that not only meets their current technical and operational requirements but also positions them for long-term efficiency, reliability, and productivity. Making the right choice today means fewer interruptions, higher product quality, and smoother, more cost-effective operations for years to come.

Conclusion

Direct drive linear motors stand at the forefront of this transformation, delivering unmatched accuracy, frictionless motion, and operational reliability. By minimizing mechanical losses, reducing maintenance needs, and enabling high-speed, repeatable motion, these motors empower businesses to produce faster, smarter, and more cost-effectively.

Choosing the right direct drive linear motor is an investment in both performance and long-term productivity. From robotics to semiconductor manufacturing, material handling, and beyond, industries that adopt this technology gain a competitive edge, unlocking higher throughput, superior product quality, and sustainable efficiency. Ultimately, direct drive linear motors are not just components, they are the driving force behind the next generation of precision, speed, and industrial innovation.