High torque electric motors are revolutionizing the way industries approach power, precision, and performance. Unlike conventional motors, they are engineered to deliver superior rotational force while maintaining efficiency and control across a wide range of applications. From automotive innovation to advanced robotics and renewable energy, these motors are driving progress in some of the most demanding fields. In this article, we’ll explore what high torque electric motors are, their defining features, key advantages, and why they are becoming indispensable in modern engineering.

What Are High Torque Electric Motors?

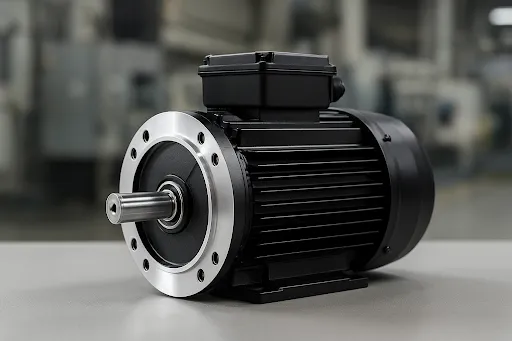

A high torque electric motor is an advanced type of electric motor specifically engineered to generate significantly greater rotational force, known as torque, compared to conventional models. Torque can be understood as the twisting power that causes motion; in practical terms, it determines how efficiently a motor can start, lift, or drive heavy loads. The higher the torque, the better the motor performs in situations that require strength, stability, and endurance.

Traditional electric motors are often designed with a focus on achieving higher speeds, which can sometimes limit their torque output. High torque electric motors, however, shift this balance by emphasizing force and control, making them capable of maintaining steady power even at low speeds. This is achieved through optimized winding designs, advanced magnetic materials, reinforced bearings, and precision construction techniques that allow the motor to perform under heavy stress without overheating or losing efficiency.

These characteristics give high torque electric motors an important role in industries where demanding tasks must be completed reliably and repeatedly. For example, they are used in electric and hybrid vehicles to provide strong acceleration, in robotics and automation to enable precise movement under load, and in industrial machinery such as CNC equipment or conveyor systems where both force and accuracy are critical. They are also increasingly adopted in renewable energy applications, like wind turbines, where consistent torque is essential for stable power generation.

In essence, high torque electric motors combine power, precision, and durability in a single solution. They are not just stronger versions of regular motors but purpose-built technologies that ensure consistent performance in some of the most demanding engineering environments.

Key Features of High Torque Electric Motors

High torque electric motors are distinguished by several core features that set them apart from standard models. These features are what make them highly reliable and effective in demanding industrial and commercial applications.

1. High Torque Output

The defining feature of these motors is their ability to deliver exceptionally strong torque. This allows them to move, lift, or drive heavy loads with ease, even at startup or low-speed conditions where conventional motors may struggle. By providing robust torque from the beginning, they ensure smooth and stable performance in critical operations.

2. Precise Control and Responsiveness

Despite their focus on power, high torque electric motors are engineered to maintain precise control over speed and movement. Advanced feedback systems and high-quality components enable responsive adjustments, making them suitable for applications where accuracy and consistency are essential such as robotics, CNC machinery, or automated assembly lines.

3. Durability and Reliability

These motors are built for tough environments and continuous operation. Reinforced bearings, optimized cooling systems, and high-grade materials ensure long service life while minimizing downtime due to mechanical wear or overheating. This durability makes them particularly well-suited for industries like automotive manufacturing, aerospace, and heavy machinery.

4. Energy Efficiency

Modern high torque electric motors are designed with efficiency in mind. Optimized winding patterns, improved magnetic materials, and advanced motor control systems reduce energy losses. As a result, they provide greater force while consuming less power, making them both cost-effective and environmentally friendly over time.

5.Versatility Across Applications

Another key feature is their adaptability. High torque electric motors can be customized to suit different industries and load requirements, from powering electric vehicles and industrial robots to driving renewable energy systems. Their ability to function reliably across such a broad spectrum makes them indispensable in modern engineering.

With these features, high torque electric motors offer a unique combination of strength, precision, and efficiency, positioning them as a superior choice for industries seeking long-term performance and reliability.

Main Advantages of High Torque Electric Motors

High torque electric motors bring multiple advantages that make them a preferred choice for industries requiring strength, precision, and efficiency. Below are the most important benefits explained in detail:

- Superior load handling: One of the biggest strengths of high torque electric motors is their ability to perform reliably under heavy loads. Unlike standard motors, which may lose momentum or stability when faced with demanding tasks, these motors provide steady torque from the moment they start.

- High precision and control: Despite their emphasis on power, high torque electric motors are engineered to deliver precise and stable movement. With advanced feedback mechanisms and optimized motor designs, they ensure accurate speed and positioning control. This is vital for fields like robotics, CNC machining, or automated manufacturing lines, where even the slightest error can compromise the final result.

- Energy efficiency: Modern high torque electric motors are designed with energy optimization in mind. By improving magnetic efficiency, reducing friction, and using optimized winding techniques, they achieve higher torque output while consuming less electricity. Over the long term, this results in lower operational costs and supports companies in reaching sustainability targets.

- Durability and reliability: Built with robust components, reinforced bearings, and efficient cooling systems, high torque electric motors are made to last. Their durability allows them to operate continuously in challenging industrial environments without overheating or breaking down.

- Future-ready adaptability: As industries increasingly adopt automation and smart technologies, high torque electric motors are designed to integrate seamlessly with advanced systems. Their combination of force, precision, and efficiency makes them suitable for robotics, automated assembly lines, and electric mobility solutions.

Together, these advantages highlight why high torque electric motors are more than just powerful machines. They represent a long-term, cost-effective solution that empowers industries to operate with greater productivity, precision, and resilience in a competitive marketplace.

Applications of High Torque Electric Motors

High torque electric motors have become indispensable across a wide range of industries, thanks to their ability to combine power, precision, and durability. Below are some of the most prominent applications where these motors are making a transformative impact.

1. Automotive Industry

In the automotive sector, high torque electric motors are at the core of innovation. They play a crucial role in electric and hybrid vehicles, where strong torque is required to achieve smooth acceleration and reliable performance on varying terrains. Unlike combustion engines that build torque gradually, electric motors can deliver maximum torque instantly, providing faster response and higher efficiency.

They are also used in power steering systems, braking systems, and other vehicle components that demand precise control alongside strong force. As the world shifts toward sustainable mobility, high torque electric motors are expected to remain a cornerstone of the automotive revolution.

2. Robotics and Automation

Robotics is another area where high torque electric motors shine. Robots are often required to lift or manipulate heavy objects with accuracy, or to perform repetitive actions that demand both strength and precision. High torque motors provide the necessary power without sacrificing fine motion control.

Some common robotic applications include:

- Industrial robotic arms that assemble products with speed and accuracy.

- Autonomous guided vehicles (AGVs) that transport heavy loads in warehouses.

- Collaborative robots (cobots) that work alongside humans safely and efficiently.

By combining force and responsiveness, these motors help automation systems achieve higher productivity while maintaining safety and quality.

3. Aerospace and Defense

The aerospace and defense industries demand equipment that can operate under extreme conditions while delivering uncompromised performance. High torque electric motors are used in aircraft actuation systems, radar positioning equipment, and even in military-grade vehicles that require reliable propulsion and control.

Their durability and ability to deliver high torque consistently make them ideal for critical operations where precision and reliability can directly impact safety and mission success.

4. Industrial Machinery and Manufacturing

In modern factories, precision and force must go hand in hand. High torque electric motors are widely adopted in CNC machinery, conveyor systems, and press machines, where consistent torque ensures both quality and efficiency.

For example, CNC machines rely on high torque motors to cut, shape, and drill materials with exact accuracy. Conveyor systems need them to transport heavy goods continuously without interruptions. By minimizing downtime and enhancing output, these motors have become central to smart manufacturing practices.

5. Renewable Energy

As renewable energy becomes a global priority, high torque electric motors are increasingly used in wind turbines and solar tracking systems. In wind energy, they ensure the smooth rotation of turbine blades, even under fluctuating wind speeds, to maximize energy generation. In solar applications, they provide the torque needed to adjust solar panels throughout the day for optimal sun exposure.

Their ability to deliver consistent power while maintaining efficiency makes them vital for the clean energy transition.

From automotive breakthroughs to renewable energy solutions, high torque electric motors prove their versatility across industries. They are not limited to one niche but serve as the backbone for technologies that require a perfect balance of strength, precision, and reliability. This wide range of applications highlights why high torque electric motors are not just tools of today, but also essential enablers of the innovations shaping tomorrow.

Choosing the Right High Torque Electric Motor

Selecting the right high torque electric motor is not just about picking the one with the highest power rating, it’s about finding the perfect balance between performance, efficiency, and long-term reliability. The right choice can significantly improve productivity, reduce equipment wear, and lower operating costs.

The first factor to consider is load requirements and operating conditions. For applications that demand continuous heavy loads, you’ll need a motor capable of maintaining consistent torque output over long periods without overheating. On the other hand, in systems with cyclical or short-term loads, a motor that handles peak torque efficiently while conserving energy may be more suitable.

Equally important is size and installation space. Modern machines often require compact motors that can deliver exceptional torque without taking up too much room. Carefully assessing the installation environment ensures you don’t overspend on oversized equipment and guarantees flexibility during future maintenance.

Energy efficiency is another critical factor. Many high torque electric motors are now designed with energy-saving technologies, which can significantly reduce electricity costs throughout the motor’s lifecycle. For facilities operating 24/7, the difference in energy efficiency translates into substantial long-term savings.

Durability and maintainability should never be overlooked. A high-quality motor should not only provide reliable performance but also be easy to service, with spare parts readily available and strong manufacturer support. Choosing a trusted supplier ensures your system remains stable, minimizing downtime and unexpected repair expenses.

In short, selecting the right high torque electric motor requires a holistic view from technical specifications and energy consumption to long-term sustainability. A wise decision will not only optimize immediate performance but also set the foundation for continuous growth and operational efficiency.

Conclusion

High torque electric motors are more than just powerful machines, they represent the fusion of strength, precision, and efficiency that today’s industries demand. From heavy-duty manufacturing to next-generation robotics and electric vehicles, these motors are redefining what’s possible in performance-driven applications. By understanding their unique features, advantages, and applications, businesses and engineers can make smarter decisions when selecting the right motor for their needs.

As technology continues to evolve, the role of high torque electric motors will only grow stronger, powering the innovations that drive progress across multiple sectors. Whether you’re seeking enhanced productivity, greater energy efficiency, or unmatched reliability, investing in the right motor is a step toward long-term success and sustainable growth.