LINEAR MOTORS FOR AUTOMOTIVE TESTING

In the race to develop smarter, safer, and more efficient vehicles, precision is no longer a luxury, it’s a necessity. From electric drivetrains to autonomous braking systems, today’s automotive components demand ultra-accurate, repeatable testing conditions. Use the linear motor for automotive testing: a breakthrough in motion technology that delivers unmatched control, speed, and reliability. As testing environments evolve, linear motors are becoming the hidden powerhouses behind the next generation of vehicle validation.

What is a Linear Motor?

A linear motor is an advanced type of electric motor that produces motion in a straight line, rather than rotational motion like conventional motors. At its core, a linear motor can be thought of as an unrolled rotary motor, where the stator and rotor are laid out flat to generate direct linear movement without the need for mechanical conversions such as gears, screws, or belts.

Unlike traditional systems that require complex linkages to convert rotary motion into linear displacement, a linear motor eliminates mechanical intermediaries entirely. This results in higher efficiency, zero backlash, and significantly improved precision and response time. In essence, linear motors offer a form of direct-drive motion, where force is applied directly to the load, resulting in ultra-smooth, accurate, and dynamic movement.

There are several key types of linear motors used across industries:

- Ironcore Linear Motors: Known for their high force density, they are ideal for demanding applications where maximum thrust is needed. However, they may experience cogging effects due to the presence of iron in the stator core.

- Ironless Linear Motors: These provide extremely smooth motion and are free of cogging, making them perfect for high-precision tasks such as semiconductor handling or sensor testing.

- U-shaped or Slotless Linear Motors: Combining compact design with versatility, these motors are often used in space-constrained environments while maintaining excellent performance.

Linear motors are not only compact and efficient but also scalable, able to be customized for applications ranging from micro-precision stages to high-thrust industrial machines. Their inherent advantages in accuracy, dynamic response, and maintenance-free operation have made them a cornerstone of modern automation, especially in automotive testing environments where reliability and repeatability are mission-critical.

As the automotive industry continues to embrace electrification, automation, and autonomous systems, the role of linear motors is becoming increasingly vital in testing processes that demand unmatched speed and control.

Why Use Linear Motors in Automotive Testing?

In today’s rapidly evolving automotive landscape, testing equipment must deliver more than just functionality. It must offer uncompromising precision, responsiveness, and reliability. This is exactly why the linear motor for automotive testing has become a preferred motion solution for OEMs and test equipment manufacturers looking to push the limits of innovation.

Precision and Repeatability Without Compromise

The accuracy of any automotive test bench depends on consistent, controllable motion. Linear motors eliminate mechanical transmission elements like belts or gears, allowing for direct-drive linear motion. This translates to zero backlash, high positional accuracy, and repeatable test cycles—ideal for applications such as brake pedal testing, ADAS sensor calibration, or vibration simulation.

High Dynamic Performance for Real-World Simulation

Automotive systems operate under rapidly changing conditions. Linear motors deliver high acceleration, fast response times, and smooth velocity control, allowing engineers to simulate real-world forces with exceptional accuracy.

Minimal Maintenance, Maximum Uptime

Unlike traditional actuators, linear motors feature non-contact operation, reducing mechanical wear and downtime. This makes the linear motor for automotive testing a durable, low-maintenance choice for long-running validation systems.

Compact, Scalable, and Future-Ready

Whether used in EV drivetrain rigs or autonomous system simulations, linear motors adapt easily to modern test setups. Their compact footprint and customization options make them a flexible solution for the growing demands of next-generation vehicle development.

4 Applications of Linear Motor for Automotive Testing

As automotive systems become more complex and performance-driven, the demand for high-precision, high-speed, and repeatable testing solutions continues to grow. The linear motor for automotive testing has become a key enabler in meeting these demands, especially in areas that require dynamic motion control and real-time simulation.

Let’s explore some of the most critical applications where linear motors are making a profound impact.

1. Brake and Accelerator Pedal Testing

One of the most common uses of linear motors in automotive testing is the simulation of driver inputs, specifically, the pressing of brake and accelerator pedals. Testing systems equipped with linear motors can replicate human-like pedal actions with micrometer accuracy and millisecond response times, making them ideal for:

- Brake system validation

- ABS/ESC testing

- Pedal force characterization

- Electric and regenerative braking behavior studies

These applications require smooth, repeatable motion across thousands of cycles, something linear motors excel at without mechanical degradation over time.

2. ADAS and Autonomous Sensor Testing

Advanced Driver Assistance Systems (ADAS) and autonomous driving rely heavily on the performance of sensors such as LiDAR, radar, and cameras. A linear motor for automotive testing allows for precise and dynamic positioning of test objects, targets, or the sensors themselves. This enables:

- Accurate simulation of moving obstacles or vehicles

- Controlled movement of sensor test rigs for calibration

- Validation of response times under varying speeds and trajectories

By enabling real-time motion control with sub-millimeter accuracy, linear motors ensure the reliability and safety of systems that support lane keeping, collision avoidance, and automated driving functions.

3. Powertrain and Drivetrain Test Benches

In the age of electric vehicles, validating the performance and durability of powertrains is critical. Linear motors are increasingly used in test benches for:

- Battery thermal expansion testing

- Drivetrain torque response simulation

- Gearbox shift actuator tests

- E-motor vibration and load simulation

Thanks to their ability to deliver high thrust force, fast acceleration, and precise stroke control, linear motors enable engineers to stress-test powertrain components under real-world driving scenarios without leaving the lab.

4. Environmental and Endurance Testing

Automotive components must withstand extreme conditions over time, including temperature changes, mechanical wear, and repeated usage. Linear motors provide the endurance and reliability needed for:

- Climate chamber testing with precise motion under varying temperatures

- Long-cycle fatigue testing of moving parts

- Seat and door latch actuation tests over hundreds of thousands of cycles

With maintenance-free operation and no mechanical contact points, linear motors offer unparalleled performance for high-cycle, high-load applications.

From simulating human input to replicating high-load dynamic forces, the linear motor for automotive testing is no longer a niche option, it’s becoming a standard in high-performance, precision-driven validation systems. As vehicles become smarter, faster, and more complex, linear motors will continue to play a crucial role in ensuring they are safe, reliable, and ready for the road.

Advantages and Disadvantages of Linear Motor for Automotive Testing Applications

In the realm of automotive testing, selecting the ideal motion technology is essential for accurately validating embedded systems and vehicle components. The linear motor for automotive testing has gained prominence due to its precision and dynamic capabilities.

However, like any technology, it comes with its own set of advantages and disadvantages. Exploring these factors helps engineers and testers make informed choices when implementing linear motors in their testing setups.

Advantages

- High Precision and Accuracy: The linear motor for automotive testing delivers exceptional precision, which is critical for simulating exact vehicle movements and sensor signals. This high accuracy improves the reliability of embedded system tests.

- Fast Response and High Speed: With direct drive mechanics, linear motors offer quick acceleration and deceleration. This fast response is vital for reproducing dynamic conditions in automotive testing, such as sudden braking or steering changes.

- Maintenance-Free Operation: Due to minimal mechanical contact, these motors require less maintenance, reducing downtime during long testing cycles common in automotive applications.

- Compact and Flexible Design: Their compact form allows easy integration into various automotive testing environments, adapting to different test requirements efficiently.

- Smooth and Quiet Operation: Smooth motion and low noise levels enhance testing environments by minimizing interference, ensuring precise data collection.

Disadvantages

- Higher Initial Investment: Compared to traditional actuators, the linear motor for automotive testing typically involves higher upfront costs, which might be a constraint for some testing facilities.

- Complex Control Requirements: Sophisticated control systems are necessary to exploit the full capabilities of linear motors, adding complexity to automotive testing setups.

- Limited Stroke Length: In certain cases, stroke length limitations may restrict use in large-scale simulations, requiring careful planning.

- Environmental Sensitivity: Exposure to harsh conditions can affect motor performance, necessitating protective measures in automotive testing environments.

Overall, the linear motor for automotive testing stands out as a powerful and precise tool that enhances the quality and effectiveness of embedded system validation. By carefully considering its advantages and disadvantages, automotive engineers can optimize their testing strategies to ensure vehicle safety, reliability, and performance in the rapidly advancing automotive landscape.

Future Trends of Linear Motors in the Automotive Industry

As the automotive industry shifts toward greater automation, electrification, and digitalization, the technologies used in vehicle development and testing are evolving rapidly. One standout innovation is the linear motor for automotive testing, which continues to gain ground thanks to its ability to meet the high precision and responsiveness required by modern vehicles. But where is this technology heading?

Let’s explore the future trends that are shaping how linear motors will redefine automotive engineering and testing in the years to come.

1. Integration with AI-Driven Testing Systems

Artificial Intelligence (AI) is becoming increasingly essential in managing complex vehicle testing procedures. Future testing platforms are expected to integrate linear motors with AI algorithms to automate dynamic adjustments, optimize test conditions, and analyze vast amounts of real-time data. This synergy will enable faster, more adaptive testing environments especially for systems like advanced driver-assistance systems (ADAS) and autonomous driving technologies.

2. Enhanced Role in EV and Battery System Testing

As electric vehicles (EVs) take center stage, the demand for precise thermal and mechanical testing of battery systems has surged. Linear motor for automotive testing setups are ideal for simulating accurate load cycles, mechanical stress, and environmental conditions on EV components. In the future, we’ll see linear motors tailored specifically for high-speed, high-load battery pack evaluations.

3. Expanded Use in Hardware-in-the-Loop (HiL) Testing

HiL testing is vital for validating embedded software before full vehicle integration. Linear motors will increasingly be used to replicate physical inputs such as pedal forces, vibrations, or steering torque—within virtual environments. Their precision and low-latency performance make them a natural fit for closed-loop simulations in next-gen automotive development workflows.

4. Modular and Scalable Testing Platforms

As vehicles become more complex, testing systems must evolve accordingly. Future linear motor platforms will likely be more modular and scalable, allowing for quick reconfiguration to accommodate different testing needs, from compact modules for in-cabin electronics to large-scale chassis testing setups. This flexibility will improve efficiency across various testing phases.

5. Sustainability and Energy Efficiency

Energy consumption and sustainability are becoming critical concerns across the automotive sector. Linear motors, already more efficient than many traditional actuation systems, will be further optimized for low energy use. Additionally, regenerative systems may be integrated to recover energy during deceleration phases in high-cycle testing scenarios.

Looking ahead, the linear motor for automotive testing will play an even greater role in pushing the boundaries of vehicle performance, safety, and innovation. Its integration with AI, relevance to EV testing, and adaptability to evolving automotive architectures position it as a core technology for the future.

Conclusion

As vehicles become smarter and more complex, the demand for precision, speed, and reliability in testing continues to rise. With its unmatched performance, the linear motor for automotive testing is not just a trend, it’s a strategic enabler for innovation, helping manufacturers validate embedded systems with confidence and efficiency in an ever-evolving industry.

Products applied in the industry

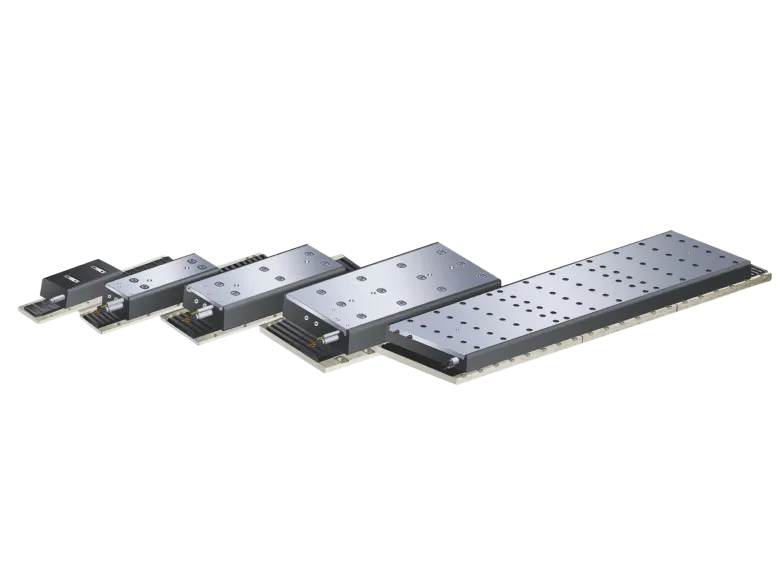

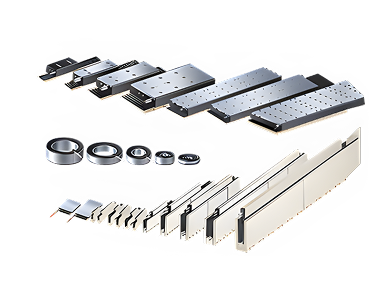

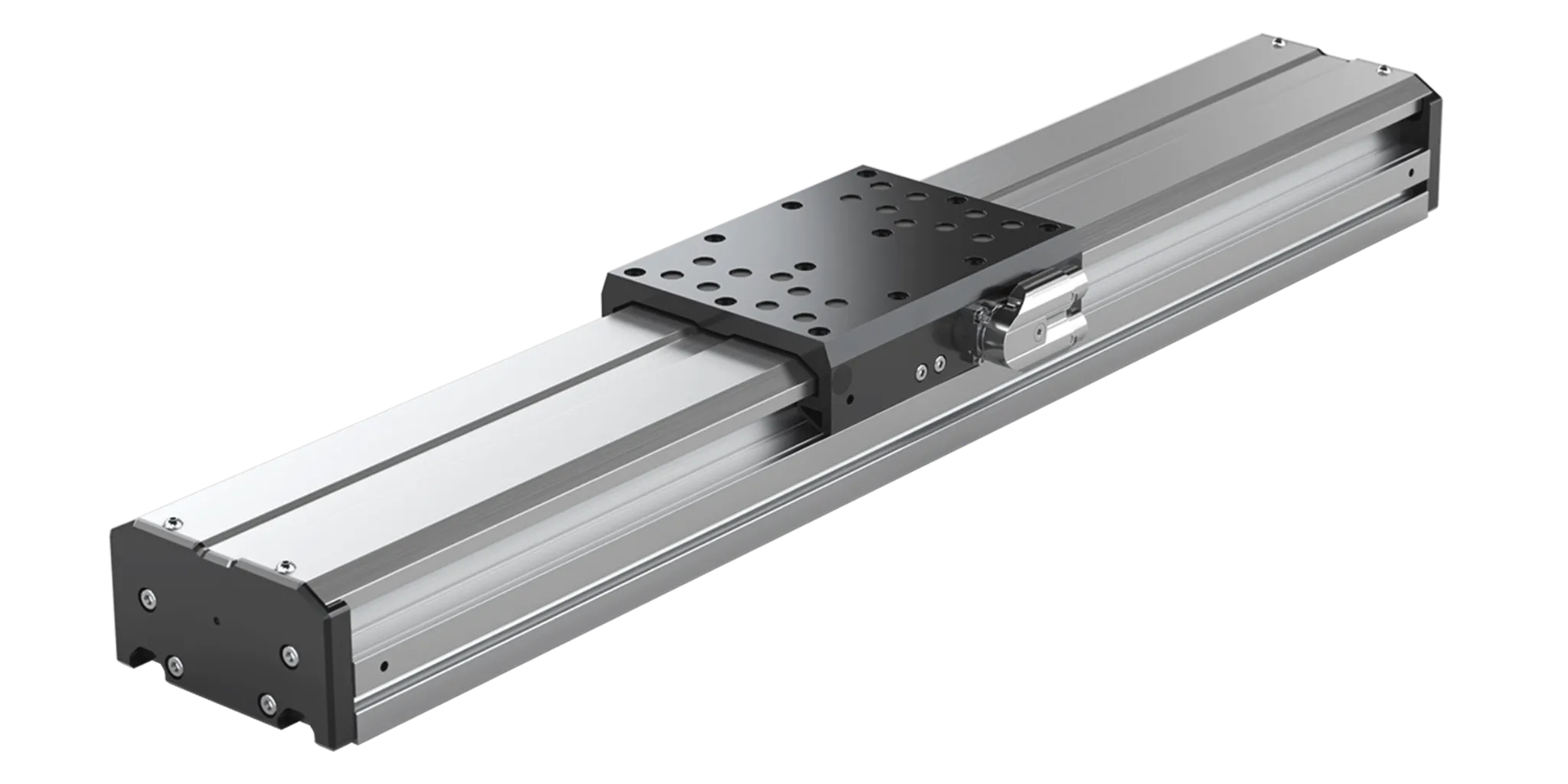

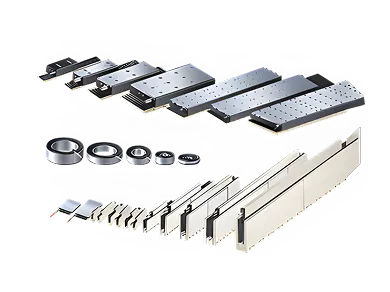

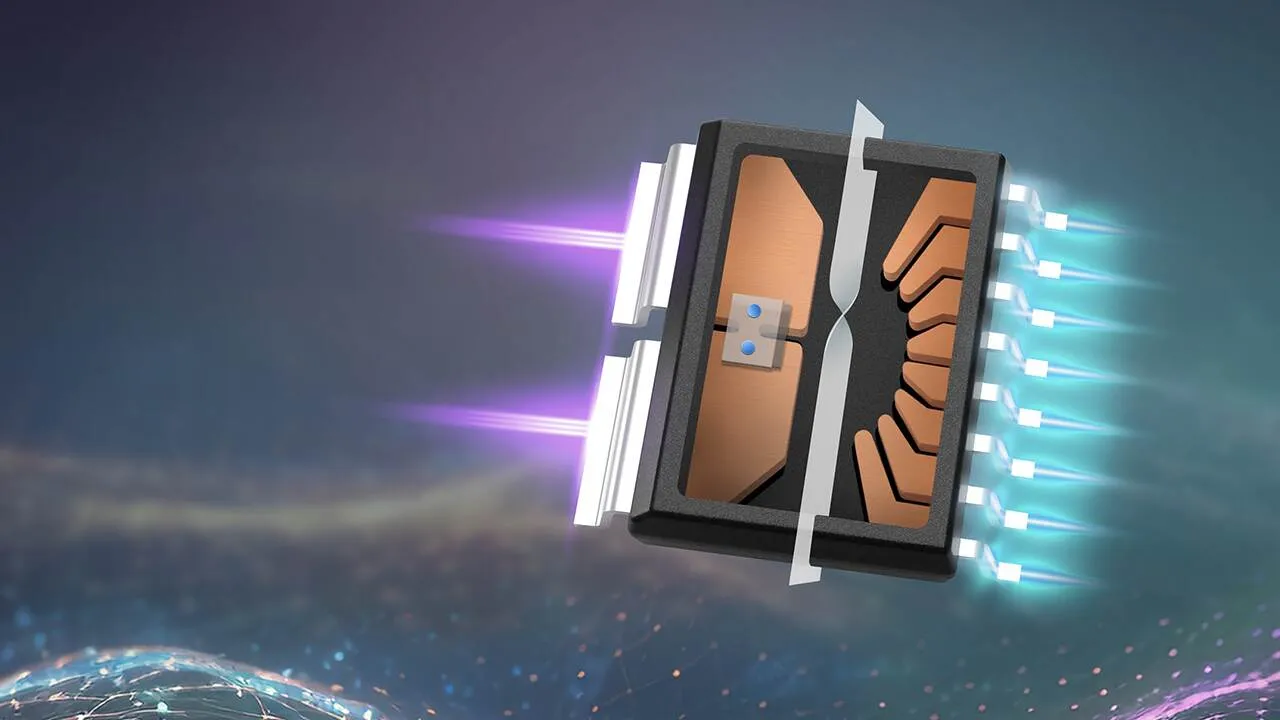

Featuring high force density and excellent thermal performance, our ironcore linear motors offer consistent and efficient motion control. Widely used in industrial automation, CNC, and packaging applications.

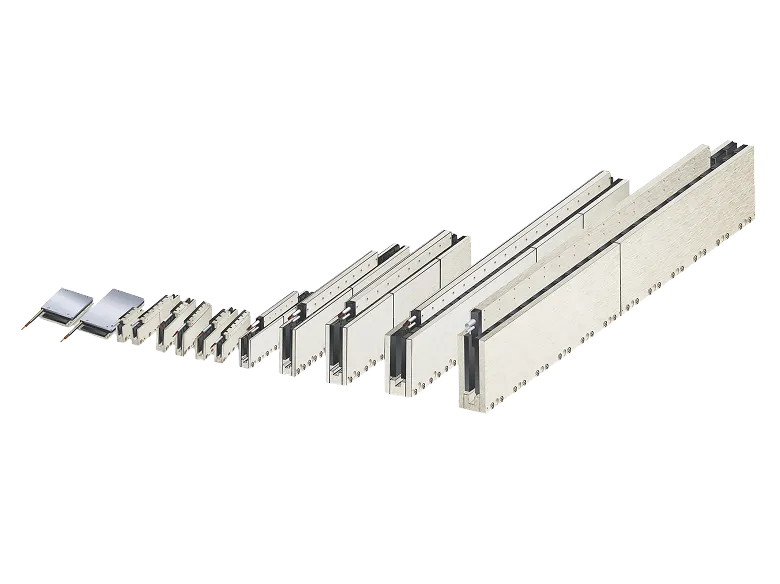

Offering ultra-smooth, cogging-free motion, these ironless linear motors are perfect for precision applications such as medical devices, metrology, and electronics manufacturing where low inertia is essential.

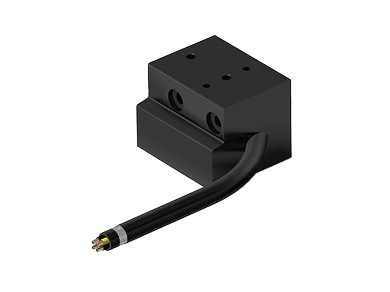

Our Hall Modules ensure precise signal feedback for improved positioning accuracy. They are compact, easy to integrate, and fully compatible with ITG linear motors and related systems.

Provide customized linear motor and OEM solutions to meet specific technical requirements, including enhanced performance, structural modifications, custom cable exits, and advanced curve linear motor configurations.

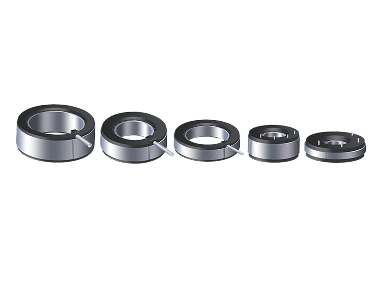

Direct-drive torque motors provide zero-backlash rotary motion with high torque and responsiveness. Ideal for robotics, rotary tables, and high-end automation that require precise control.

Designed for high-vacuum environments, delivering strong thrust and precision. Ideal for semiconductor, display, and scientific equipment requiring clean, stable, and high-performance motion systems.

Latest News & Articles

In modern motor control systems, precision is not just a performance advantage, it is a fundamental requirement. From industrial automation and robotics to servo drives and linear motors, accurately measuring

In industrial motion systems, performance is often judged by speed, torque, and precision, but one critical factor is frequently overlooked: shaft design. The choice between a solid shaft motor and

In modern industrial automation, motion is no longer limited to straight lines or simple rotations. As production systems demand higher speed, greater flexibility, and more compact machine layouts, curved linear

Room 401, Building 7#, No.26, Qinghua Road, Phase ll of Science & Technology Innovation Park, Xushuguan Town, SND, Suzhou

itgmotor_sz@126.com

+86 139.140.332.75