LINEAR MOTOR IN SEMICONDUCTOR INDUSTRY

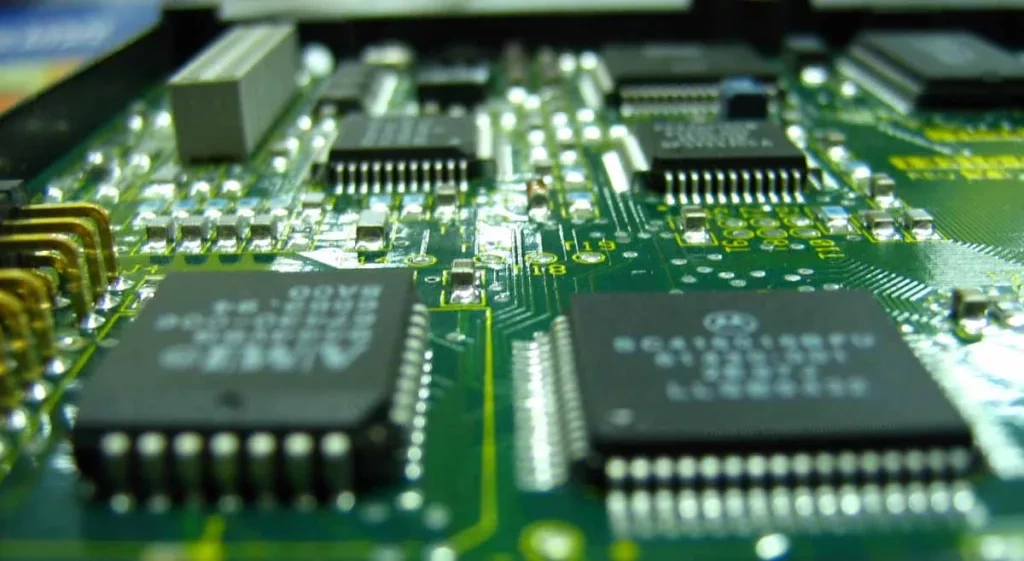

As semiconductor devices continue to scale down in size while increasing in complexity, the demand for ultra-precise, high-speed motion control has become more critical than ever. Linear motors have emerged as a key enabler in advanced semiconductor manufacturing, offering contactless motion, exceptional repeatability, and compatibility with cleanroom and vacuum environments. From wafer inspection to photolithography, linear motor in semiconductor equipment are setting new standards for performance and reliability.

What is a Linear Motor and Its Relevance in Semiconductor Manufacturing?

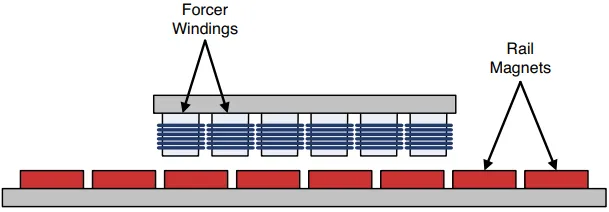

A linear motor is an advanced motion device that converts electrical energy directly into linear motion without the need for mechanical transmission elements such as ball screws, belts, or gears.

Unlike rotary motors, which require additional components to translate motion, linear motors produce straight-line movement natively, resulting in faster response times, higher positioning accuracy, and lower mechanical wear.

In the context of semiconductor manufacturing, these advantages are not merely desirable, they are essential. As the industry pursues increasingly smaller geometries and tighter tolerances, even the slightest vibration or positional error can lead to defective wafers or reduced yield. Linear motors provide the precision and smooth motion control required to handle these complex and delicate processes with confidence.

Moreover, linear motors excel in cleanroom and vacuum environments, two conditions that are fundamental in semiconductor fabrication. Their non-contact design eliminates particle generation caused by friction, ensuring compliance with stringent contamination standards. Additionally, the absence of backlash or mechanical play makes them ideal for applications requiring sub-micron or nanometer-level repeatability.

From wafer alignment to die bonding, linear motors are now embedded in the most critical stages of semiconductor production. Their role is no longer optional, but foundational to the performance and reliability of modern semiconductor equipment.

Key Applications of Linear Motors in Semiconductor Industry

Linear motor in semiconductor manufacturing are increasingly essential across critical process stages, where precision motion control, contamination-free operation, and speed are non-negotiable.

Their direct-drive, contactless design enables highly accurate, repeatable movement making them an ideal fit for modern fabrication lines. Below are some of the most impactful application areas where linear motors are setting new standards in performance and reliability.

1. Photolithography Systems

Photolithography is one of the most demanding steps in semiconductor manufacturing, requiring nanometer-level stage positioning. Linear motors control wafer and reticle stages with extreme precision and minimal vibration, ensuring perfect image alignment and critical dimension accuracy in every layer.

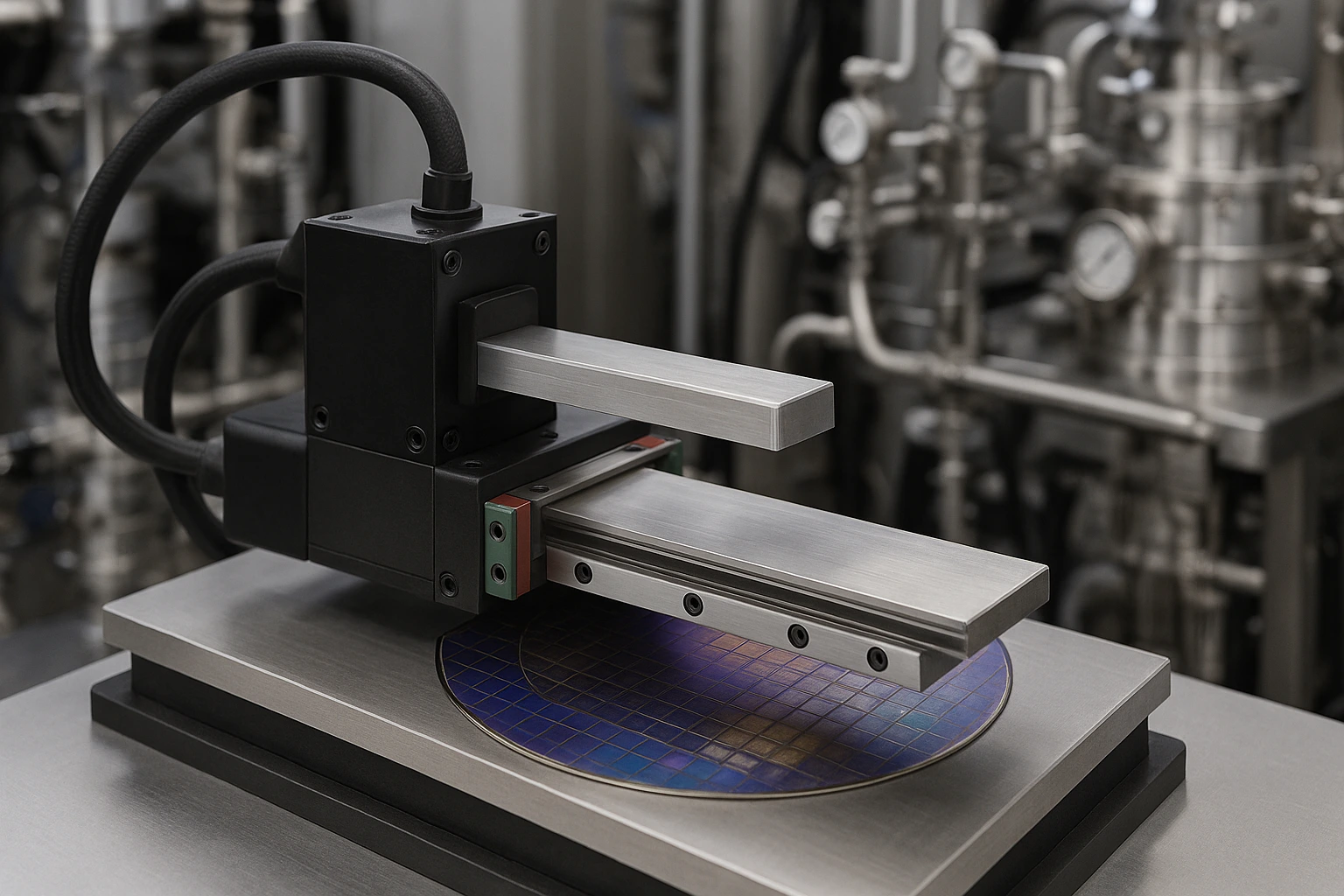

2. Wafer Inspection and Metrology

Inspection tools must scan wafers quickly and steadily to detect sub-micron defects and ensure device integrity. The precision motion control offered by linear motors allows for high-speed scanning without compromising accuracy – critical for maintaining both yield and throughput.

3. Etching and Deposition Equipment

In vacuum-based processes like plasma etching or thin-film deposition, linear motors offer stable, frictionless movement without generating particulates. Their vacuum-compatible designs make them a reliable motion solution in contamination-sensitive environments.

4. Wafer Handling and Transfer

From loading wafers into tools to moving them between stages, linear motor in semiconductor automation enable smooth, reliable transfer with high repeatability. This contributes to faster cycle times and greater automation efficiency across the fab.

5. Die Bonding and Packaging

At the backend of the process, packaging equipment demands ultra-fine alignment. Linear motors deliver precise placement for die attach and interconnect applications, especially important for high-density packaging formats like 2.5D and 3D ICs.

5 Benefits of Using Linear Motor in Semiconductor Equipment

The use of linear motor in semiconductor equipment has rapidly become a cornerstone technology as the industry demands ever-greater precision, speed, and reliability. Unlike traditional mechanical drive systems, linear motors offer direct linear motion without intermediate components such as ball screws, belts, or gears.

This fundamental difference unlocks a range of critical advantages that directly address the unique challenges in semiconductor manufacturing. Below, we explore in depth the key benefits that make linear motors indispensable in modern fabs.

1. High Precision and Exceptional Repeatability

Precision is paramount in semiconductor manufacturing, where even nanometer-scale deviations can impact yield and device performance. Linear motor in semiconductor applications provide unmatched accuracy by eliminating mechanical transmission elements that typically introduce backlash, compliance, or hysteresis.

With direct electromagnetic force, linear motors offer near-instantaneous response and highly repeatable positioning, often achieving sub-micron or even nanometer resolution.

This extreme precision supports critical processes such as wafer alignment during photolithography, where accurate overlay of multiple layers is essential, or die bonding in packaging, where components must be placed within microns of tolerance. The ability to maintain consistent, repeatable motion cycle after cycle reduces variation and improves overall product quality.

2. Superior Speed and Smooth Motion Control

The semiconductor industry requires rapid yet stable motion to maintain high throughput. The linear motor in semiconductor systems offers smooth, frictionless movement, allowing for high acceleration and velocity without vibration or mechanical resonance.

As a result, linear motors achieve much higher acceleration and velocity profiles, allowing equipment to operate at faster cycle times without sacrificing positional accuracy. The smooth and continuous force output reduces vibration and mechanical resonance, minimizing disturbances that can degrade process precision.

This capability is particularly valuable in wafer inspection systems and pick-and-place machines, where both speed and stability directly influence throughput and yield.

3. Maintenance-Free Operation and Longevity

Unlike mechanical systems with gears or belts that wear over time, the linear motor in semiconductor equipment features contactless operation, significantly reducing mechanical wear and the need for frequent maintenance.

In contrast, the non-contact design of linear motors eliminates these wear points. With no physical contact between moving parts, linear motors experience minimal mechanical fatigue, resulting in longer service life and more consistent performance.

This translates into significantly reduced maintenance downtime, lower operational costs, and higher equipment availability factors that are critical in semiconductor fabs where production interruptions can be costly and difficult to recover from.

Furthermore, the reliability of linear motors helps maintain stable process conditions, ensuring repeatability and quality over extended production runs.

4. Cleanroom and Vacuum Environment Compatibility

Maintaining cleanliness is paramount in semiconductor fabs. The linear motor in semiconductor applications generates minimal particles due to their non-contact design, making them ideal for cleanroom environments.

Moreover, many linear motors are specially designed to function reliably in vacuum environments, avoiding issues such as outgassing and lubrication failure. This capability is crucial for processes like plasma etching and thin-film deposition, where vacuum integrity must be preserved.

The compatibility of linear motors with these environments ensures that manufacturers can meet strict contamination standards while maintaining high-performance motion control.

5. Compactness and Design Flexibility

As semiconductor equipment becomes more complex and compact, the motion system must fit within constrained spaces without compromising performance. Linear motors offer a slim profile and modular architecture, enabling designers to integrate high-performance motion control into tight spaces.

This compactness also supports flexible machine designs that can be easily customized or upgraded to meet evolving manufacturing requirements. Linear motors can be configured for different travel lengths, force outputs, and mounting arrangements, making them adaptable to a wide range of semiconductor equipment applications—from wafer scanners to automated handling systems.

In summary, the integration of linear motor in semiconductor manufacturing equipment delivers transformative benefits—combining unparalleled precision, speed, reliability, and cleanliness. These advantages empower semiconductor manufacturers to meet the increasing demands for smaller, more complex devices while improving throughput and maintaining stringent quality standards.

Products applied in the industry

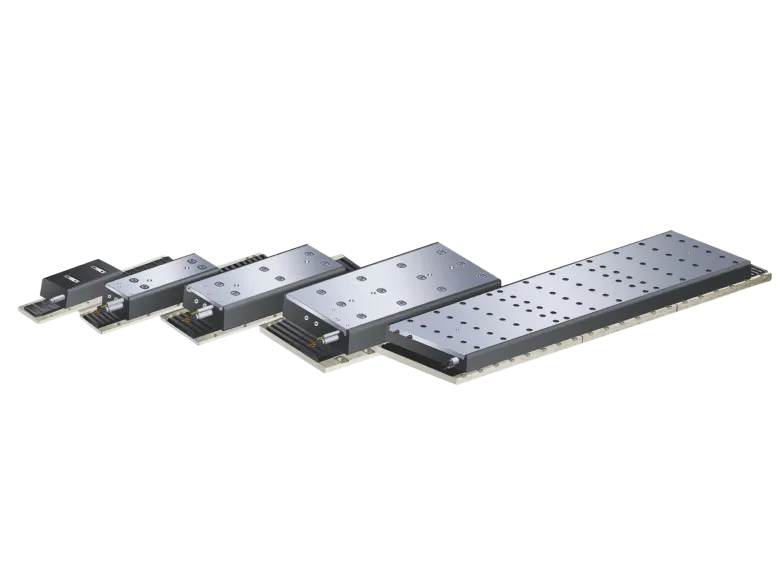

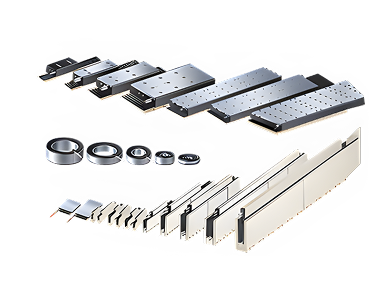

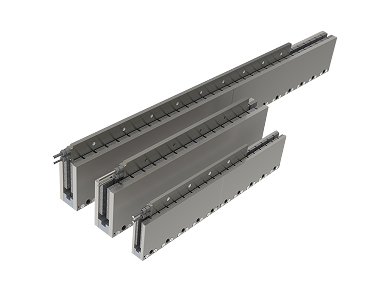

Featuring high force density and excellent thermal performance, our ironcore linear motors offer consistent and efficient motion control. Widely used in industrial automation, CNC, and packaging applications.

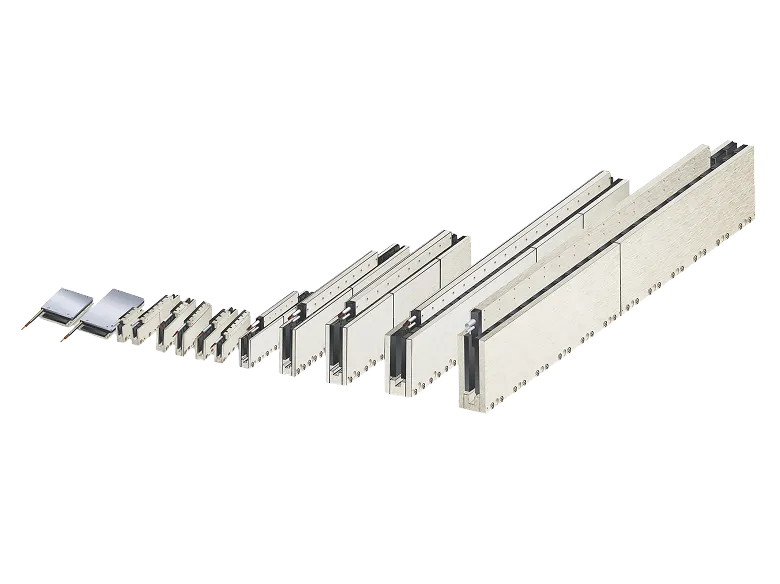

Offering ultra-smooth, cogging-free motion, these ironless linear motors are perfect for precision applications such as medical devices, metrology, and electronics manufacturing where low inertia is essential.

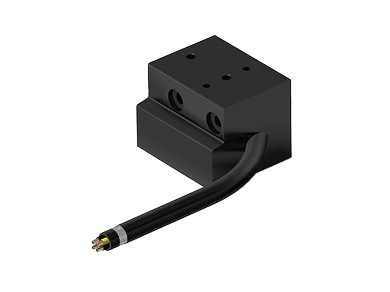

Our Hall Modules ensure precise signal feedback for improved positioning accuracy. They are compact, easy to integrate, and fully compatible with ITG linear motors and related systems.

Provide customized linear motor and OEM solutions to meet specific technical requirements, including enhanced performance, structural modifications, custom cable exits, and advanced curve linear motor configurations.

Direct-drive torque motors provide zero-backlash rotary motion with high torque and responsiveness. Ideal for robotics, rotary tables, and high-end automation that require precise control.

Designed for high-vacuum environments, delivering strong thrust and precision. Ideal for semiconductor, display, and scientific equipment requiring clean, stable, and high-performance motion systems.

Latest News & Articles

In industrial motion systems, performance is often judged by speed, torque, and precision, but one critical factor is frequently overlooked: shaft design. The choice between a solid shaft motor and

In modern industrial automation, motion is no longer limited to straight lines or simple rotations. As production systems demand higher speed, greater flexibility, and more compact machine layouts, curved linear

Precision, speed, and motion stability define the performance limits of modern automation systems. As industrial applications demand smoother trajectories, higher positioning accuracy, and shorter cycle times, conventional rotary-driven mechanisms increasingly

Room 401, Building 7#, No.26, Qinghua Road, Phase ll of Science & Technology Innovation Park, Xushuguan Town, SND, Suzhou

itgmotor_sz@126.com

+86 139.140.332.75