LINEAR MOTOR ITG APPLICATIONS IN SCIENCE AND AEROSPACE

In the demanding fields of scientific research and aerospace engineering, precision, reliability, and durability are non-negotiable. At ITG, we deliver advanced motor and drive solutions tailored to meet the stringent requirements of laboratories, testing systems, and aerospace applications. Our high-performance motors play a crucial role in enabling innovation from the laboratory bench to the outer edge of the atmosphere.

1. Precision Motors for Scientific Instruments

Driving Accuracy in Research and Laboratory Settings

Scientific research thrives on detail. Whether analyzing DNA sequences, measuring chemical properties, or testing material responses under stress, researchers depend on machines that offer reliable and repeatable performance. Inaccurate motion, however slight, can compromise the validity of an experiment or skew results in critical studies.

ITG’s motors are designed with the sensitivity and consistency required by laboratories, research centers, and universities worldwide. Our motors support the function of key lab instruments such as:

- Centrifuges and mixers that require stable, high-speed rotation

- Spectrometers and chromatographs used in analytical chemistry

- Microfluidic systems and pipetting robots in biotechnology labs

- Optical adjustment and micro-positioning platforms in physics and nano-engineering

These systems demand low noise, minimal vibration, and high control accuracy, all hallmarks of ITG’s motor solutions.

Optimized for Stability, Integration, and Longevity

Our motors can be integrated into complex control systems, including closed-loop feedback setups with encoders, allowing for precise position and speed monitoring. In applications where accuracy at the micron level is required, ITG motors enable smooth and continuous motion, critical for long-term data collection and stability.

With robust housing and long operational lifespans, they are suitable for 24/7 use in lab environments, where equipment uptime is paramount.

2. High-Reliability Solutions for Aerospace Ground Systems

While the glamour of aerospace often lies in flight and orbit, a tremendous amount of work takes place on the ground. Aircraft assembly lines, maintenance platforms, engine testing stations, and pilot simulators all rely on advanced motion control systems to function efficiently and safely.

ITG provides motor solutions that drive:

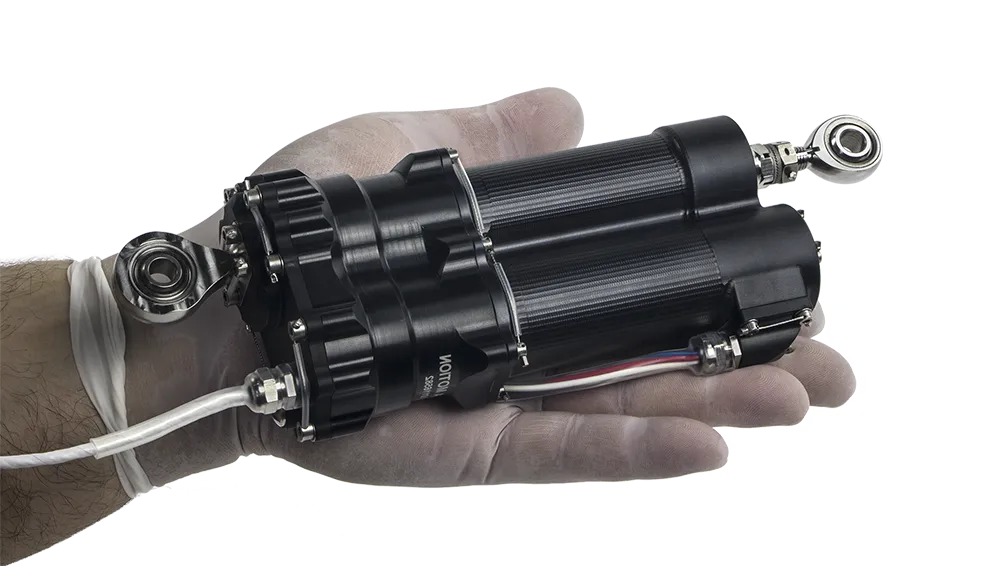

- Door and hatch actuation systems on aircraft and test stands

- Rotating platforms and lifts used in aerospace component assembly

- Automated material handling systems in manufacturing environments

- Flight simulator motion systems, providing realistic training feedback

- Fan and cooling system drives for ground-based engine testing rigs

These systems operate under harsh mechanical conditions, heavy loads, long duty cycles, and exposure to industrial contaminants. ITG motors are engineered for resilience, with enhanced sealing, temperature tolerance, and overload protection.

All of our products for aerospace ground systems comply with the relevant international safety and performance standards, including those required by major aerospace manufacturers and suppliers. We understand the compliance expectations and documentation needs of the aerospace supply chain, and we build to meet them.

3. Motion Control for Space and Simulation Technologies

Pushing the Limits in Harsh Environments

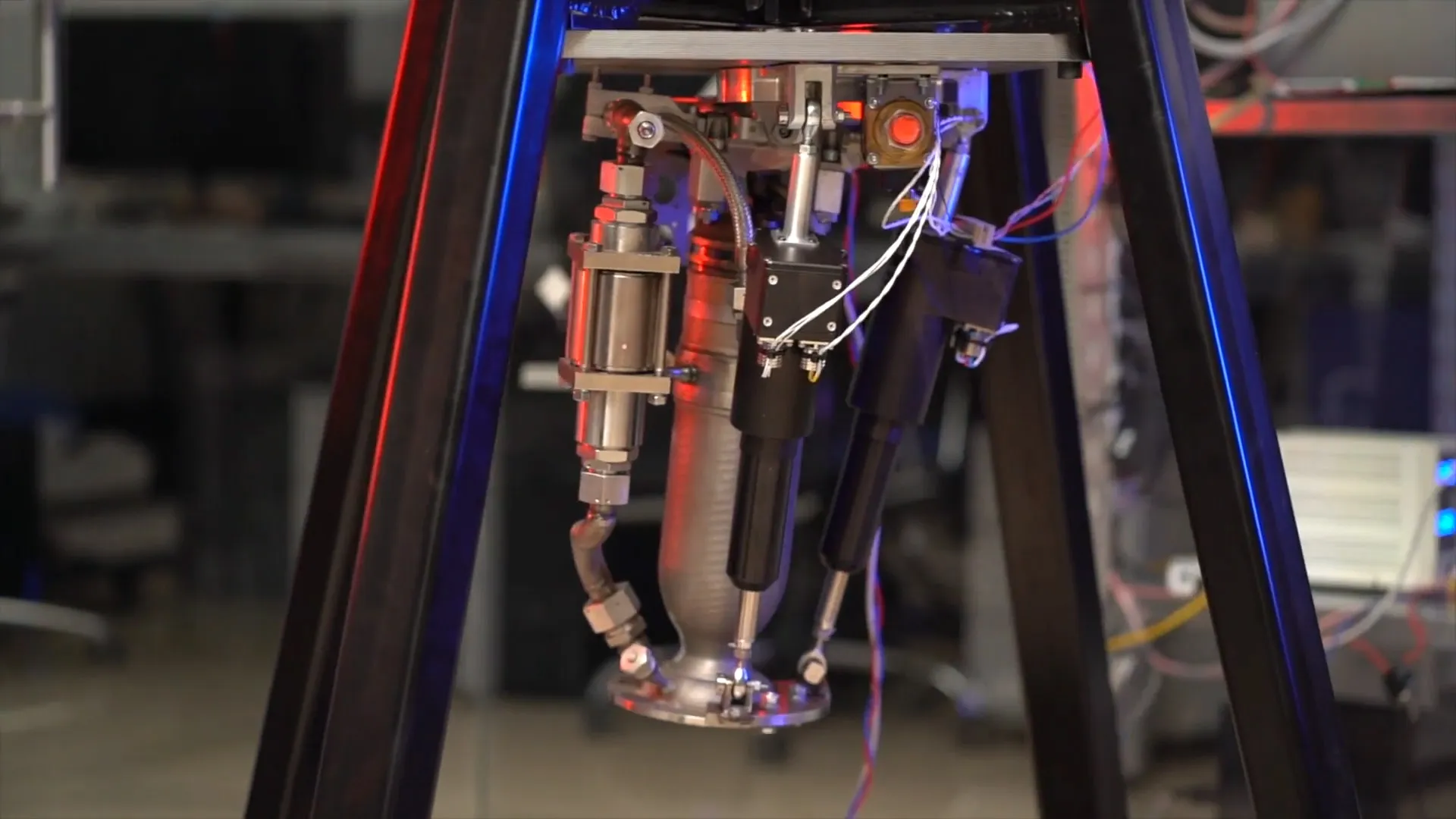

Space is arguably the most demanding environment for engineering systems. There is no room for error in orbit, where vacuum conditions, radiation, thermal extremes, and mechanical stress converge. ITG supplies specialized motors and drives that are suited for integration in:

- Satellite orientation and positioning systems

- Gimbal systems for space-based cameras and sensors

- Thermal vacuum chambers and testing platforms simulating space conditions

- Optical instruments, such as telescopes and spectrographs used in astrophysics

- Cleanroom-grade robotic arms used in microgravity experiments

Our motors are available in brushless DC, stepper, and servo configurations, with options for vacuum compatibility, magnetic shielding, and compact sizing for payload-sensitive designs.

Reliable Motion When It Matters Most

We understand that motors used in space technology must operate flawlessly across a wide temperature range, resist radiation-induced degradation, and often function with limited cooling or maintenance. Our engineering team collaborates with clients to select or develop the right motor characteristics, balancing torque density, electrical efficiency, and mechanical resilience.

With ITG, you can count on motors that are not only powerful and precise but also rigorously tested for mission-critical performance.

4. Custom Engineering for Specialized Science and Aerospace Projects

Scientific and aerospace applications are rarely off-the-shelf. The diversity of projects from climate research drones to lunar rover prototypes requires a motion control partner capable of providing not just parts, but tailored solutions. ITG offers extensive custom engineering services, including:

- Custom shaft lengths, gear ratios, and torque curves

- Specialized mounting brackets and enclosure designs

- Integration with sensors, encoders, or programmable controllers

- Enhanced thermal management systems for high-heat environments

- Interface compatibility with aerospace-grade power and communication protocols

Whether you are building a one-off prototype or planning full-scale production, ITG engineers are here to collaborate at every stage of your project.

We go beyond supplying components and become your engineering partner. Our support begins at the design consultation phase and continues through testing, deployment, and lifecycle optimization. With CAD modeling, simulation support, and deep technical knowledge, we ensure that every motor or drive you receive is a precise fit both mechanically and operationally.

Why Choose ITG for Science and Aerospace Applications?

Partnering with ITG means working with a team that understands the stakes. We have years of experience delivering motion control solutions to industries where failure is not an option. Here’s what sets us apart:

- Technical Expertise: Deep understanding of scientific and aerospace motion requirements

- Quality and Durability: Products built to perform consistently under stress

- Customization Capabilities: Tailored solutions to fit unique challenges

- Regulatory Compliance: Built to meet global aerospace and lab safety standards

- Collaborative Approach: Engineers who work as part of your team

Our goal is not only to supply products, but to enable progress whether that means a breakthrough in the lab or a safer, smarter aircraft on the runway.

Conclusion

In science and aerospace, success is measured in microns and milliseconds. It depends on the reliability of every component, the accuracy of every system, and the integrity of every design. At ITG, we embrace this responsibility with passion and precision, delivering motor solutions that meet the most demanding expectations in the world.

If your project requires motion control that won’t compromise under pressure, let’s talk. Explore our portfolio of motors, request a consultation, or contact our engineering team today. Together, we can turn the impossible into motion.

Products applied in the industry

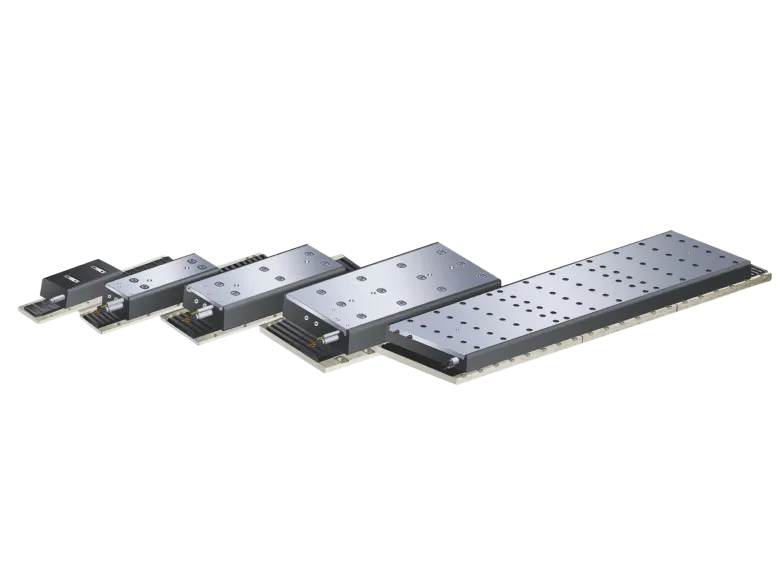

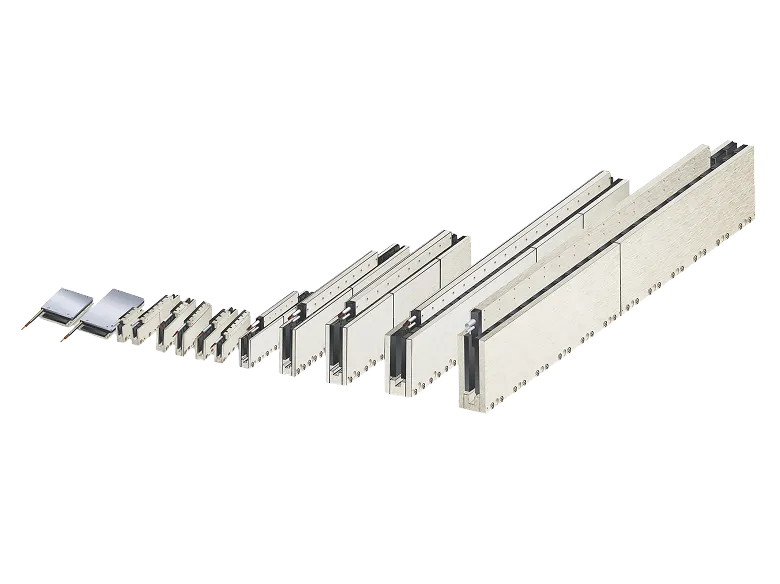

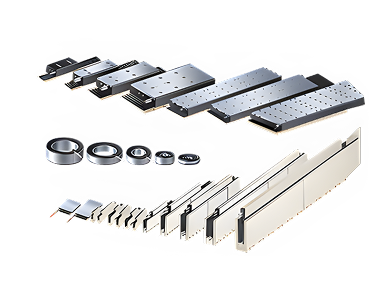

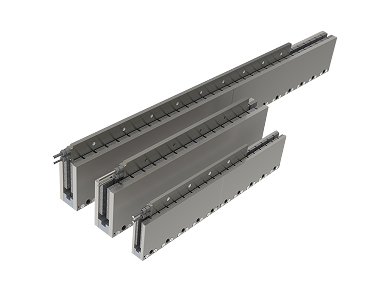

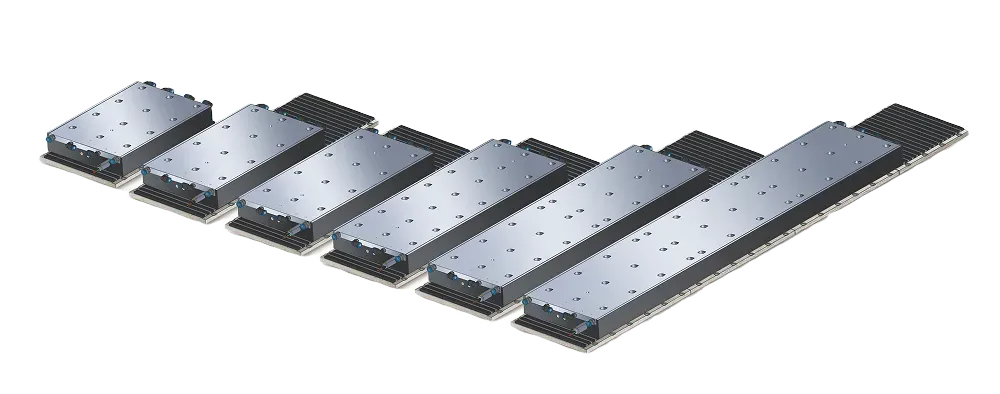

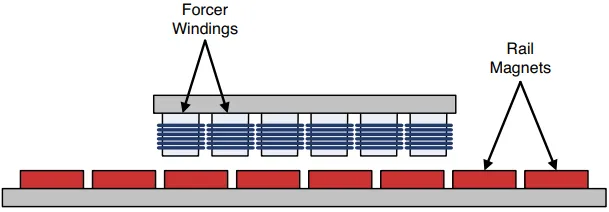

Featuring high force density and excellent thermal performance, our ironcore linear motors offer consistent and efficient motion control. Widely used in industrial automation, CNC, and packaging applications.

Offering ultra-smooth, cogging-free motion, these ironless linear motors are perfect for precision applications such as medical devices, metrology, and electronics manufacturing where low inertia is essential.

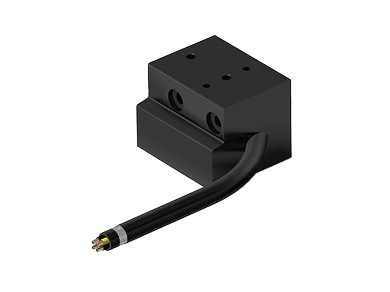

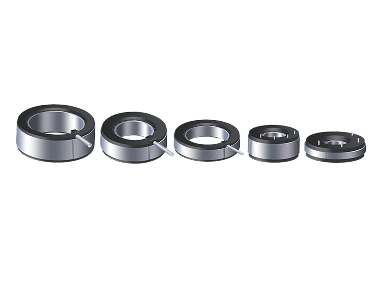

Our Hall Modules ensure precise signal feedback for improved positioning accuracy. They are compact, easy to integrate, and fully compatible with ITG linear motors and related systems.

Provide customized linear motor and OEM solutions to meet specific technical requirements, including enhanced performance, structural modifications, custom cable exits, and advanced curve linear motor configurations.

Direct-drive torque motors provide zero-backlash rotary motion with high torque and responsiveness. Ideal for robotics, rotary tables, and high-end automation that require precise control.

Designed for high-vacuum environments, delivering strong thrust and precision. Ideal for semiconductor, display, and scientific equipment requiring clean, stable, and high-performance motion systems.

Latest News & Articles

In industrial motion systems, performance is often judged by speed, torque, and precision, but one critical factor is frequently overlooked: shaft design. The choice between a solid shaft motor and

In modern industrial automation, motion is no longer limited to straight lines or simple rotations. As production systems demand higher speed, greater flexibility, and more compact machine layouts, curved linear

Precision, speed, and motion stability define the performance limits of modern automation systems. As industrial applications demand smoother trajectories, higher positioning accuracy, and shorter cycle times, conventional rotary-driven mechanisms increasingly

Room 401, Building 7#, No.26, Qinghua Road, Phase ll of Science & Technology Innovation Park, Xushuguan Town, SND, Suzhou

itgmotor_sz@126.com

+86 139.140.332.75