HOW ITG LINEAR AND TORQUE MOTORS DRIVE ADVANCED ROBOTICS SOLUTIONS

As the robotics industry advances toward faster, smarter, and more compact systems, motion control has become the core enabler of robotic performance. From precision pick-and-place arms to collaborative robots (cobots), autonomous mobile robots (AMRs), and semiconductor handling systems, the need for high-torque, high-precision, and low-maintenance motors is greater than ever.

ITG Linear & Torque Motor Manufacturer offers a specialized portfolio of direct drive motors—both linear and rotary—that deliver the precision, force density, and smooth operation demanded by modern robotics applications.

KEY APPLICATIONS OF ITG MOTORS IN ROBOTICS

1. Collaborative Robot Joints (Cobots)

Cobots require high-torque, compact rotary actuators with precise feedback for safe human-machine interaction. ITG torque motors, especially frameless and hollow shaft designs, enable:

-

High torque in compact form factor

-

Smooth and silent operation (ideal for shared workspaces)

-

Direct integration into robot joints for reduced inertia

2. SCARA and Delta Robots

High-speed pick-and-place robots operate under demanding cycle times. Linear axes must accelerate rapidly while maintaining consistent precision.

ITG ironless linear motors provide:

-

Cog-free, low-mass motion—critical for acceleration

-

Precise and repeatable positioning

-

Maintenance-free operation for 24/7 uptime

3. Autonomous Mobile Robots (AMRs)

AMRs in warehouses and cleanrooms require precise drive systems and lifting/handling modules. Torque motors provide silent, low-profile wheel drive solutions, while linear motors handle lifting platforms with smooth, jerk-free vertical motion.

Advantages:

-

No gearboxes = reduced mechanical noise and wear

-

Compact profiles enable tight turning radius and slim designs

4. Semiconductor Handling & Wafer Robots

In wafer processing, die sorting, and probe testing, ultra-clean motion is critical. Vacuum-compatible ironless linear motors from ITG ensure:

-

Particle-free motion for cleanroom compliance

-

Nanometer-level precision for submicron alignment

-

Low heat generation for thermal-sensitive environments

5. Inspection & Assembly Gantries

For multi-axis gantry robots in inspection, PCB assembly, and battery production lines, ITG motors enable:

-

Fast multi-axis synchronization

-

Precision motion for camera inspection or component placement

-

Modular integration with EtherCAT or CANopen control systems

WHY ROBOTICS ENGINEERS CHOOSE ITG

| Feature | Benefit in Robotics Application |

|---|---|

| Frameless Torque Motor Design | Enables direct drive in robot joints with compact integration |

| Cog-Free Linear Motors | Smooth, stable motion ideal for high-speed and vision-based tasks |

| Vacuum Compatibility | Suitable for cleanroom & semiconductor automation |

| High Torque Density | Delivers force in tight spaces without compromising performance |

| Zero Backlash Operation | Improves control and feedback in dynamic robotic systems |

| Custom Form Factors | Designed to fit specialized robot arms, platforms, or compact AMRs |

SAMPLE APPLICATION: COBOT ARM ACTUATION

An industrial automation company in Japan integrated ITG frameless TMXSL105 torque motors into the shoulder and elbow joints of a collaborative robotic arm. Combined with harmonic reducers and absolute encoders:

-

The arm achieved ±0.02° repeatability

-

Reduced actuator noise by 60% compared to geared servos

-

Operated 24/7 without lubrication or gearbox replacement

WHEN CUSTOM MOTORS ARE REQUIRED IN ROBOTICS

Custom ITG motor solutions are ideal when:

-

Joints or axes have unusual geometry or compact dimensions

-

Environmental constraints require vacuum or IP-rated designs

-

Advanced feedback (e.g., BISS-C, EnDat) is needed for control loops

-

High thermal stability is essential in tightly packed robotic arms

Products applied in the industry

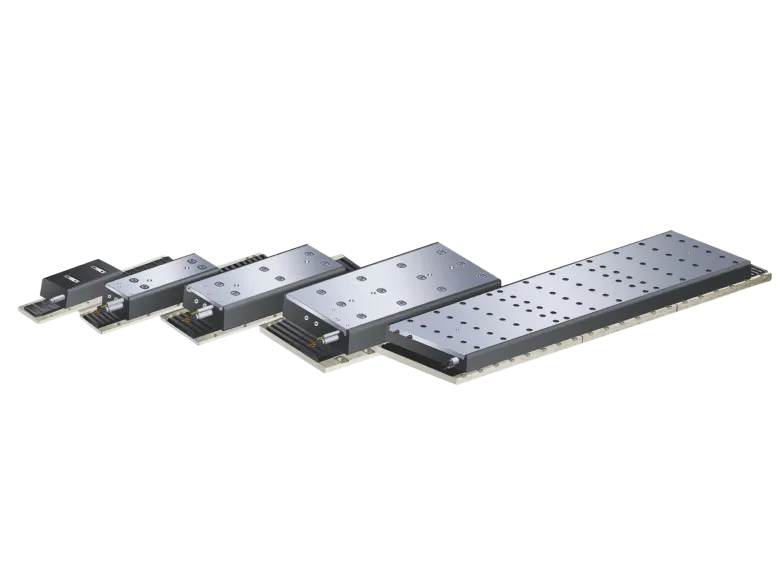

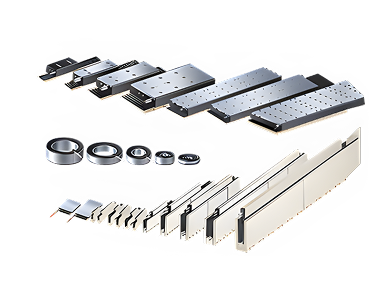

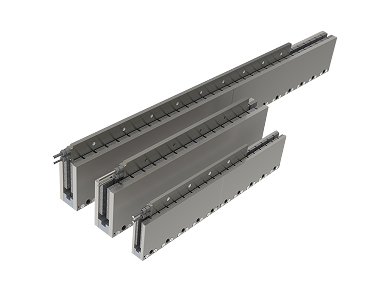

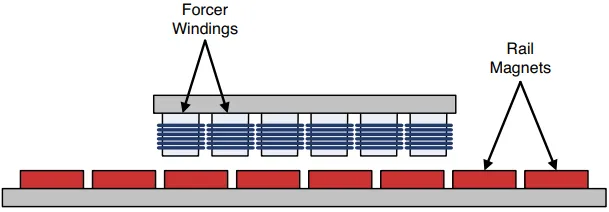

Featuring high force density and excellent thermal performance, our ironcore linear motors offer consistent and efficient motion control. Widely used in industrial automation, CNC, and packaging applications.

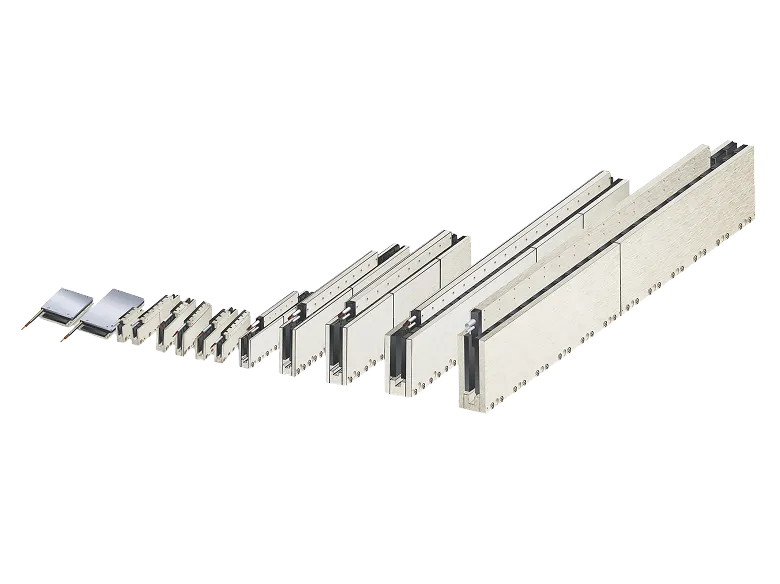

Offering ultra-smooth, cogging-free motion, these ironless linear motors are perfect for precision applications such as medical devices, metrology, and electronics manufacturing where low inertia is essential.

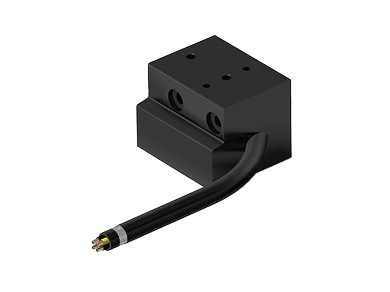

Our Hall Modules ensure precise signal feedback for improved positioning accuracy. They are compact, easy to integrate, and fully compatible with ITG linear motors and related systems.

Provide customized linear motor and OEM solutions to meet specific technical requirements, including enhanced performance, structural modifications, custom cable exits, and advanced curve linear motor configurations.

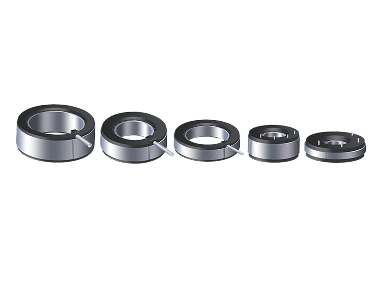

Direct-drive torque motors provide zero-backlash rotary motion with high torque and responsiveness. Ideal for robotics, rotary tables, and high-end automation that require precise control.

Designed for high-vacuum environments, delivering strong thrust and precision. Ideal for semiconductor, display, and scientific equipment requiring clean, stable, and high-performance motion systems.

Latest News & Articles

In industrial motion systems, performance is often judged by speed, torque, and precision, but one critical factor is frequently overlooked: shaft design. The choice between a solid shaft motor and

In modern industrial automation, motion is no longer limited to straight lines or simple rotations. As production systems demand higher speed, greater flexibility, and more compact machine layouts, curved linear

Precision, speed, and motion stability define the performance limits of modern automation systems. As industrial applications demand smoother trajectories, higher positioning accuracy, and shorter cycle times, conventional rotary-driven mechanisms increasingly

Room 401, Building 7#, No.26, Qinghua Road, Phase ll of Science & Technology Innovation Park, Xushuguan Town, SND, Suzhou

itgmotor_sz@126.com

+86 139.140.332.75