HOW ITG LINEAR AND TORQUE MOTORS POWER THE NEXT GENERATION OF INDUSTRIAL PRINTING SYSTEMS

In the fast-evolving world of industrial printing, precision, speed, and modularity are no longer just competitive advantages—they are essential operational requirements. As industries demand tighter tolerances, faster throughput, and reduced downtime, motion systems must evolve to match these expectations. At the forefront of this evolution are linear motors and torque motors, and among the companies delivering cutting-edge solutions in this field, ITG Linear & Torque Motor Manufacturer stands out for its technical depth, adaptability, and focus on performance.

This article explores the real-world applications of ITG’s motor systems across various segments of the printing industry, offering insights that help decision-makers, engineers, and automation integrators understand how to effectively upgrade their systems using ITG technology.

INDUSTRIAL PRINTING SEGMENTS THAT BENEFIT FROM ITG MOTORS

1. Commercial Offset Printing

Offset printing systems operate at high speeds and produce massive volumes, often for newspapers, packaging, and large-scale advertising. These systems require precise control over the feeding, tensioning, and alignment of paper rolls. Traditional mechanical systems using belts and pulleys introduce backlash, vibration, and maintenance complexity.

ITG torque motors, especially hollow shaft variants, are engineered to eliminate mechanical transmission components. They allow for direct control over roller shafts and unwinding systems, delivering smooth and powerful rotation with zero backlash. This ensures that the paper path remains consistent, reducing registration errors and enabling continuous 24/7 operation with minimal intervention. The result is not only better print quality but also longer machine uptime and lower operational costs.

2. High-Speed Digital Printing

Unlike offset, digital printing systems must control the movement of lightweight but high-precision print heads that operate at very high speeds. In these scenarios, any mechanical vibration or delay in movement directly affects print resolution and consistency.

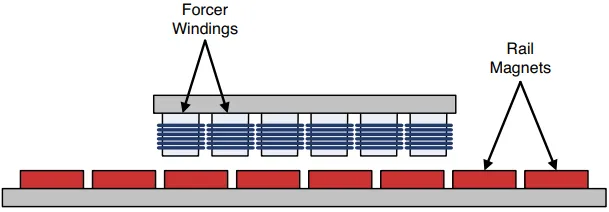

ITG ironless linear motors excel in these environments. Without iron in the forcer, they offer a lightweight design that enables ultra-smooth, rapid acceleration and deceleration, with no cogging. This feature is essential for maintaining clean image edges, fine text, and perfect color placement. The absence of mechanical contact also means there is virtually no wear and tear, making them ideal for continuous-use environments where downtime is not an option.

3. Label and Packaging Printing

In packaging and label printing, precise registration between layers is critical, especially in multi-step processes like printing, lamination, die-cutting, and quality inspection. Each motion stage must synchronize perfectly to avoid waste and ensure compliance with brand guidelines.

ITG linear motors provide the dynamic force required for fast, stop-and-start actions with millisecond precision. Meanwhile, torque motors manage roll tensioning and material feed-in with micro-level stability. This combination allows packaging systems to increase throughput without sacrificing accuracy, enabling features like variable data printing, on-the-fly changes, and alignment corrections in real time.

4. Direct-to-Shape (DTS) Printing

As product customization becomes a market differentiator, direct-to-shape (DTS) printing is becoming increasingly relevant. Printing directly onto cylindrical or irregular surfaces such as bottles, jars, and tubes introduces complex motion requirements. These systems must coordinate rotational and linear motion with exact timing.

ITG offers a hybrid motion solution for DTS applications. Torque motors provide high-torque, high-precision rotation, especially for hollow objects, while linear motors manage the X-Y translation of print heads. This dual-axis control ensures that ink deposition remains stable and synchronized with surface geometry, enabling full 360° printing with high-definition output.

5. Laser Engraving, UV Printing, and PCB Marking

These high-precision printing methods demand extremely stable motion in environments often constrained by cleanroom requirements or electromagnetic sensitivity. In semiconductor, electronics, or high-end packaging production, even minor vibrations or electromagnetic noise can affect print results.

Vacuum-compatible ironless linear motors from ITG are purpose-built for such environments. Their non-magnetic, non-contact structure ensures zero particle generation, low thermal output, and ultra-silent operation. These motors are often used in combination with granite bases, air bearings, and active vibration isolation systems to achieve nanometer-level stability.

WHY MOTION CONTROL MATTERS IN PRINTING PERFORMANCE

Print Quality Depends on Motion Fidelity

In high-resolution printing, any deviation in the motion profile—whether acceleration, speed variation, or overshoot—can translate directly into visible print errors. Misregistration, color shift, and inconsistent dot placement are often caused by imperfect motion systems. ITG motors are engineered to provide smooth motion profiles with real-time feedback and high responsiveness, ensuring that every print stroke aligns perfectly with the intended path.

Speed Without Sacrificing Accuracy

Modern printing systems must balance two competing demands: speed and precision. Many legacy systems can print fast or accurately, but rarely both. ITG’s direct drive motors, especially when integrated with closed-loop feedback systems, enable machines to operate at high cycle rates while maintaining micron-level precision.

Lower Maintenance and Total Cost of Ownership

By eliminating gearboxes, belts, and mechanical couplings, ITG motors reduce the number of components that can fail. This leads to less scheduled maintenance, fewer unplanned downtimes, and longer system lifespan. For operations running multiple shifts or high-volume jobs, this translates directly into savings in both manpower and cost.

Modular System Design

OEMs and system integrators increasingly demand flexible components that can be easily incorporated into modular systems. ITG motors are designed with a wide range of customizable parameters—stroke length, force, feedback type, housing design—making them ideal for scalable architectures in smart factories and Industry 4.0 environments.

WHEN DO YOU NEED A CUSTOM MOTOR FROM ITG?

While ITG offers a comprehensive catalog of standard motors, certain applications demand a custom-engineered solution. Here are key scenarios where a custom motor becomes essential:

1. Unique Mechanical Constraints

If your printing equipment has unusual form factors, space limitations, or mounting requirements, standard motors may not fit. ITG can tailor the motor’s housing, flange, and mounting holes to align perfectly with your machine design.

2. Specialized Force or Torque Requirements

Some printing applications require extremely high thrust or continuous torque under compact sizes. In such cases, ITG can modify coil configurations, magnet materials, or winding density to deliver the required output.

3. Integration with Proprietary Control Systems

If your system uses a unique control architecture or feedback protocol (e.g., custom encoders, fieldbus communication), a custom motor with compatible feedback devices or interface options can ensure seamless integration.

4. Cleanroom or Vacuum Compliance

For printing environments with strict ISO class or vacuum requirements, ITG can build motors using non-outgassing materials, special coatings, or zero-particle construction techniques.

5. Performance Tuning for High-End Applications

When maximum accuracy, ultra-low noise, or sub-micron repeatability is needed—such as in PCB or micro-text printing—custom tuning of magnetic balance, thermal management, and dynamic response may be required.

6. Co-Development for OEMs

If you’re designing a new generation of printing machines, working with ITG from the early stage allows for motor and machine to be co-developed, optimizing both performance and manufacturability.

Custom motors are not just about “fitting”—they are about enabling higher-level innovation and unlocking capabilities that standard parts cannot achieve.

WHY CHOOSE ITG FOR INDUSTRIAL PRINTING APPLICATIONS?

| Feature | Advantage for Printing Applications |

|---|---|

| Customized Design Options | Tailored to fit mechanical constraints and performance requirements |

| Vacuum and Cleanroom Ready | Compatible with PCB, UV, and semiconductor applications |

| Industrial Bus Compatibility | Supports EtherCAT, CANopen, and other communication standards |

| Fast Engineering Support | CAD drawings, motor sizing, and simulation support for OEMs and integrators |

| Global Quality Standards | Built for export markets in Germany, Japan, France, and more |

| Low TCO and Long Lifecycle | Efficient, reliable operation with minimal maintenance overhead |

SAMPLE APPLICATION CONFIGURATIONS

✅ Label Printing System – South Korea

- Motors used: TMXSL105 (for tension control), IL59 (for printhead movement)

- Outcome: Reduced registration error by 40%, increased production speed by 28%

✅ Inline UV Printing Line – Germany

- Motors used: IL91C for scanning, TM133 for substrate transport

- Outcome: Achieved 1.5 m/s operation speed with no print banding or vibration artifacts

NEXT STEPS FOR BUYERS & INTEGRATORS

Every printing platform has unique requirements, and ITG is committed to helping you configure the best-fit motor solution for your application. Whether you’re retrofitting an existing line or developing a new system from scratch, ITG offers a powerful motion foundation that integrates seamlessly into your workflow.

🔧 Need technical consultation or custom motor specs? 👉 Contact our application engineers for a free assessment.

Products applied in the industry

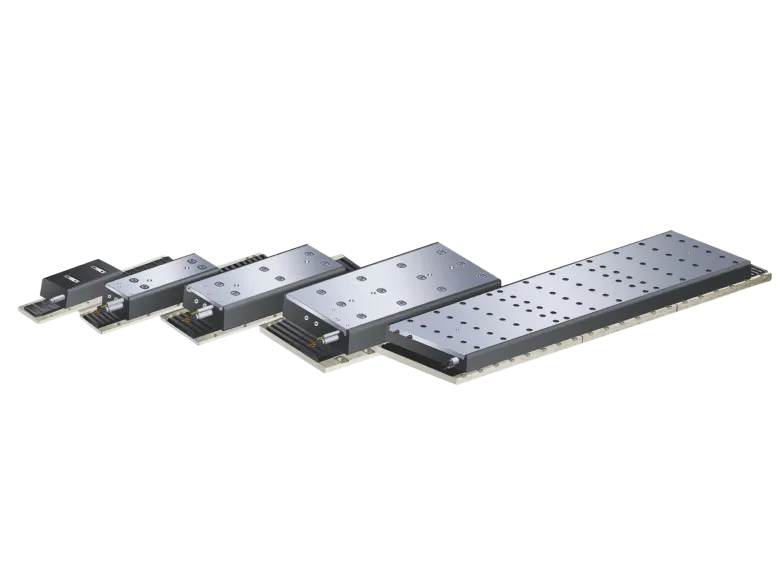

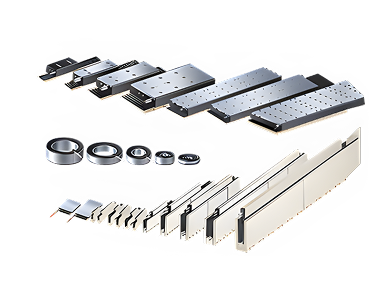

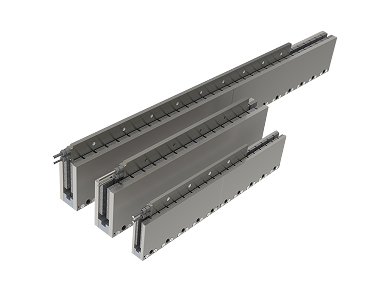

Featuring high force density and excellent thermal performance, our ironcore linear motors offer consistent and efficient motion control. Widely used in industrial automation, CNC, and packaging applications.

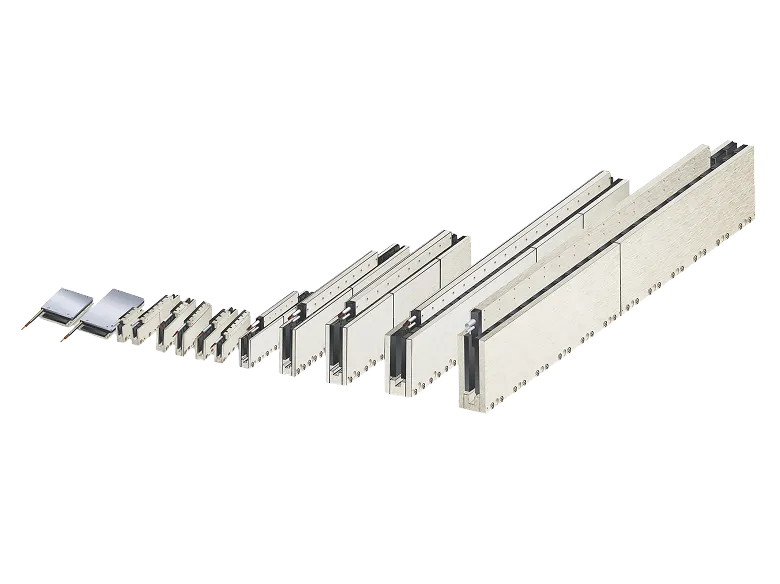

Offering ultra-smooth, cogging-free motion, these ironless linear motors are perfect for precision applications such as medical devices, metrology, and electronics manufacturing where low inertia is essential.

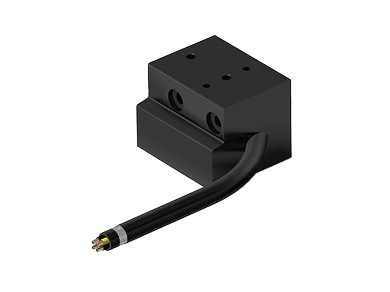

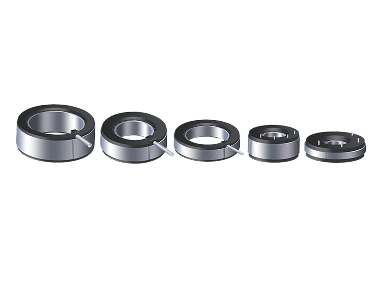

Our Hall Modules ensure precise signal feedback for improved positioning accuracy. They are compact, easy to integrate, and fully compatible with ITG linear motors and related systems.

Provide customized linear motor and OEM solutions to meet specific technical requirements, including enhanced performance, structural modifications, custom cable exits, and advanced curve linear motor configurations.

Direct-drive torque motors provide zero-backlash rotary motion with high torque and responsiveness. Ideal for robotics, rotary tables, and high-end automation that require precise control.

Designed for high-vacuum environments, delivering strong thrust and precision. Ideal for semiconductor, display, and scientific equipment requiring clean, stable, and high-performance motion systems.

Latest News & Articles

In industrial motion systems, performance is often judged by speed, torque, and precision, but one critical factor is frequently overlooked: shaft design. The choice between a solid shaft motor and

In modern industrial automation, motion is no longer limited to straight lines or simple rotations. As production systems demand higher speed, greater flexibility, and more compact machine layouts, curved linear

Precision, speed, and motion stability define the performance limits of modern automation systems. As industrial applications demand smoother trajectories, higher positioning accuracy, and shorter cycle times, conventional rotary-driven mechanisms increasingly

Room 401, Building 7#, No.26, Qinghua Road, Phase ll of Science & Technology Innovation Park, Xushuguan Town, SND, Suzhou

itgmotor_sz@126.com

+86 139.140.332.75