HOW ITG MOTORS ENHANCE DIGITAL CUTTING SYSTEMS WITH SPEED AND PRECISION

As manufacturing industries move toward mass customization and shorter lead times, digital cutting systems are becoming central to modern production workflows. Whether in packaging, signage, textile, or composite materials, these systems demand exceptional motion performance to deliver clean cuts, high throughput, and material versatility.

At the heart of this performance lies motion control technology. ITG’s linear and torque motors are engineered to meet the unique demands of digital cutting systems—delivering speed, stability, and modularity across a wide variety of configurations.

WHY DIGITAL CUTTING DEMANDS SUPERIOR MOTION CONTROL

Digital cutting involves precise movements of cutting heads, tool changers, and material handling components. Unlike traditional mechanical systems, digital cutters must perform complex cut paths (including curves, perforations, and kiss-cuts) on a wide range of materials—from corrugated cardboard and vinyl to composites and foam.

This requires:

-

High-speed acceleration and deceleration

-

Micron-level positioning accuracy

-

Zero backlash and minimal vibration

-

Flexible integration into multi-axis architectures

Conventional stepper systems or belt drives struggle with these requirements. That’s where ITG comes in.

APPLICATIONS OF ITG LINEAR AND TORQUE MOTORS IN DIGITAL CUTTING

1. X-Y Gantry Movement for Cutting Heads

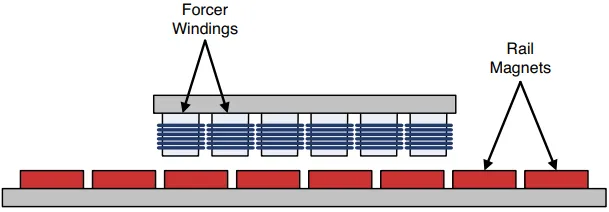

In most flatbed and conveyor-based cutters, the X and Y axes must move the cutting head with speed and precision. ITG ironless linear motors are perfect for this purpose:

-

High dynamic response enables rapid starts and stops for intricate paths.

-

Cog-free design eliminates motion ripple—critical for cutting smooth curves and sharp corners.

-

No mechanical transmission means lower maintenance and higher uptime.

2. Z-Axis Tool Control

For tools such as oscillating blades, creasers, and routers, vertical motion control is essential. ITG motors provide:

-

Stable and compact linear actuators for vertical positioning.

-

Optional force feedback integration for kiss-cutting and pressure control.

3. Material Feeding and Tensioning

Roll-fed digital cutting systems must ensure precise tension and feed control, especially when dealing with flexible substrates. ITG torque motors (including hollow-shaft models) are ideal for driving rollers with:

-

Direct-drive torque delivery

-

Zero-backlash and real-time response to tension variations

4. Rotary Tools and Knife Rotation

Advanced cutting systems may include rotary knives or rotary die cutters. Here, ITG’s torque motors offer compact, high-torque rotation with precise angle control—supporting features like contour cutting and adaptive cutting heads.

5. Multi-Head Synchronization

Multi-tool gantries require real-time synchronization of several axes. With support for EtherCAT and CANopen, ITG motors integrate seamlessly into high-level control systems, enabling tight coordination between heads and conveyors.

ADVANTAGES OF USING ITG MOTORS FOR DIGITAL CUTTING

| Feature | Benefit in Cutting Operations |

|---|---|

| Ironless Linear Motor | High-speed, cog-free motion ideal for intricate paths |

| Torque Motor (Hollow Shaft) | Smooth rotation of rollers and rotary cutters |

| Compact Design | Fits tight gantry spaces or modular tool heads |

| Long Life, No Wear Parts | Direct drive eliminates belts, pulleys, and associated maintenance |

| High-Speed Feedback Loops | Enables precision at high cutting speeds |

| Customizable Configuration | Tailored length, force, and feedback integration |

CASE STUDY: DIGITAL CUTTING SYSTEM FOR SIGNAGE & DISPLAY

A European signage equipment manufacturer upgraded their X-Y gantry system with ITG IL91 linear motors and replaced belt-driven roller feed with TMXSL105 torque motors. The results:

-

Increased cut speed by 32%

-

Reduced vibration and material slippage

-

Lowered maintenance frequency by 50%

-

Enabled seamless cutting of foam board, PET, and vinyl without head adjustment

WHEN TO CONSIDER CUSTOM MOTORS FROM ITG

If your cutting system features:

-

Extra-wide gantries or extra-long strokes

-

Vacuum tables in cleanroom or low-dust environments

-

Tools that require integrated force or pressure sensing

-

Tight space constraints in head design

Then a custom linear or torque motor from ITG can be configured to fit your specs—offering better performance and mechanical integration.

Products applied in the industry

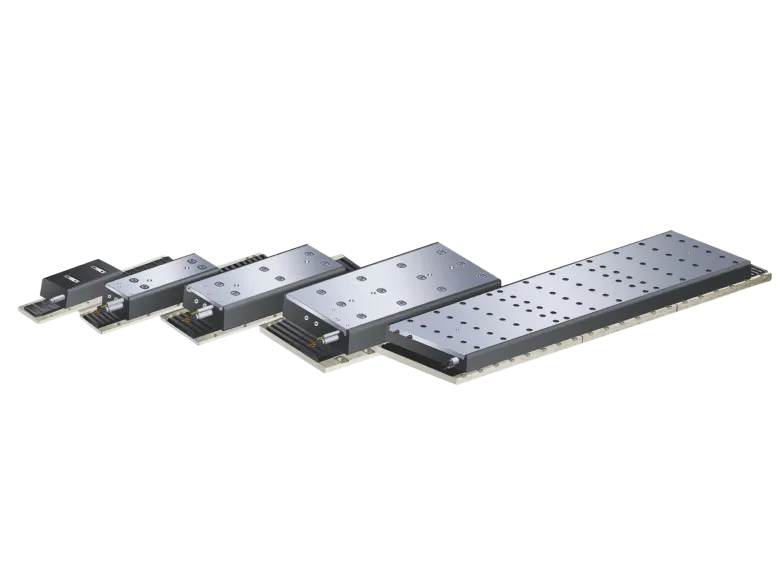

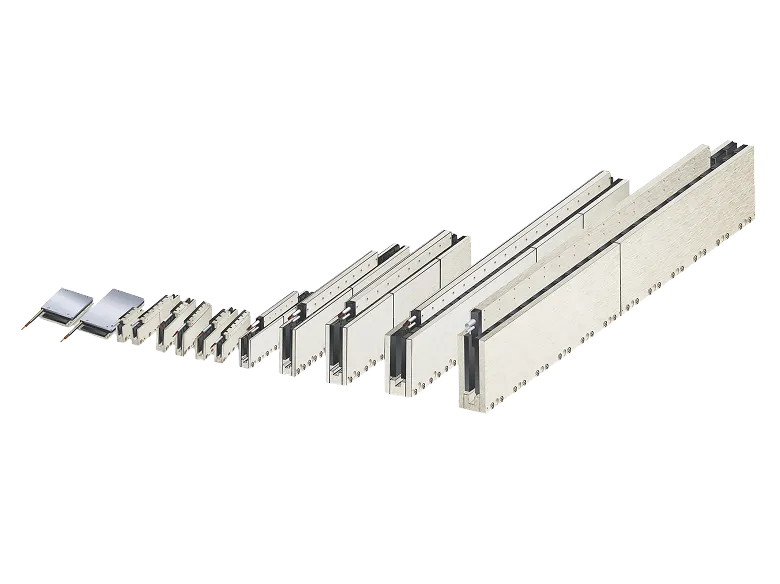

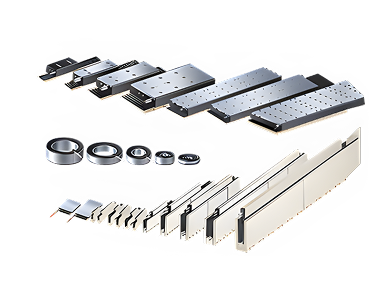

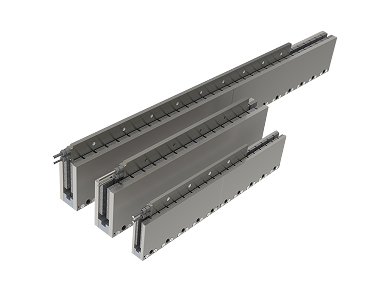

Featuring high force density and excellent thermal performance, our ironcore linear motors offer consistent and efficient motion control. Widely used in industrial automation, CNC, and packaging applications.

Offering ultra-smooth, cogging-free motion, these ironless linear motors are perfect for precision applications such as medical devices, metrology, and electronics manufacturing where low inertia is essential.

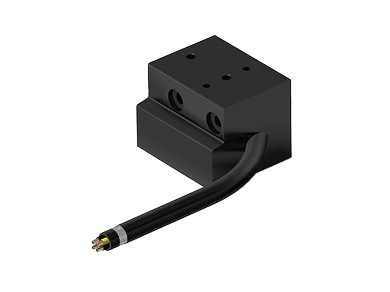

Our Hall Modules ensure precise signal feedback for improved positioning accuracy. They are compact, easy to integrate, and fully compatible with ITG linear motors and related systems.

Provide customized linear motor and OEM solutions to meet specific technical requirements, including enhanced performance, structural modifications, custom cable exits, and advanced curve linear motor configurations.

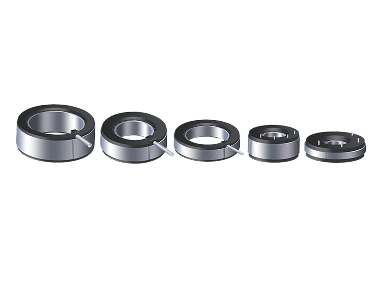

Direct-drive torque motors provide zero-backlash rotary motion with high torque and responsiveness. Ideal for robotics, rotary tables, and high-end automation that require precise control.

Designed for high-vacuum environments, delivering strong thrust and precision. Ideal for semiconductor, display, and scientific equipment requiring clean, stable, and high-performance motion systems.

Latest News & Articles

In industrial motion systems, performance is often judged by speed, torque, and precision, but one critical factor is frequently overlooked: shaft design. The choice between a solid shaft motor and

In modern industrial automation, motion is no longer limited to straight lines or simple rotations. As production systems demand higher speed, greater flexibility, and more compact machine layouts, curved linear

Precision, speed, and motion stability define the performance limits of modern automation systems. As industrial applications demand smoother trajectories, higher positioning accuracy, and shorter cycle times, conventional rotary-driven mechanisms increasingly

Room 401, Building 7#, No.26, Qinghua Road, Phase ll of Science & Technology Innovation Park, Xushuguan Town, SND, Suzhou

itgmotor_sz@126.com

+86 139.140.332.75