Traditional motion systems, once the backbone of industrial automation, are now being challenged by a new generation of technology: linear motion drives. Designed to deliver direct, frictionless movement with exceptional accuracy, these systems are transforming how machines perform and how factories operate.

From robotics to semiconductor production, linear motion drives are setting new benchmarks for performance and reliability. But what exactly makes them superior to conventional motion systems and why are more manufacturers turning to this innovation? Let’s uncover the answers.

Understanding Linear Motion Drives and Traditional Motion Systems

What Is a Linear Motion Drive?

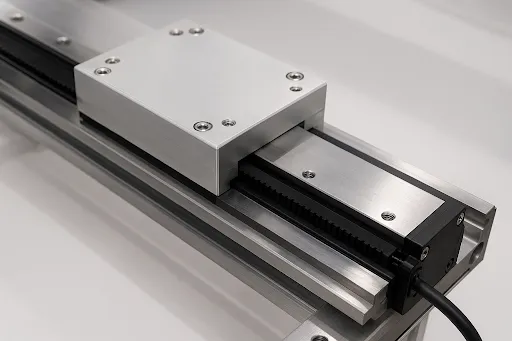

A linear motion drive is a type of motion control system designed to produce direct linear movement, without the need for mechanical conversion from rotary motion. Unlike traditional motors that spin a shaft and rely on gears or screws to create motion, a linear motor moves the load straight along a track, powered by electromagnetic force.

The core of a linear motion drive typically consists of two parts:

- The stator (primary part), which contains the electromagnetic coils, and

- The forcer or moving part, which interacts with the magnetic field to create direct motion.

Because it eliminates intermediate components such as belts, pulleys, or ball screws, a linear motion drive can achieve faster acceleration, higher precision, and smoother motion. This direct-drive technology is especially critical in high-speed, high-accuracy applications like semiconductor assembly, robotics, and precision manufacturing.

In simple terms, linear motion drives transform electrical energy directly into linear motion, no mechanical losses, no backlash, and no compromise on accuracy.

How Traditional Motion Systems Work

Before linear technology became mainstream, traditional motion systems dominated industrial automation. These setups rely on rotary motors that convert rotational motion into linear movement through mechanical components such as lead screws, rack-and-pinion gears, or timing belts.

While these systems have been reliable for decades, their design introduces inherent limitations:

- Mechanical friction between moving parts causes wear, heat, and energy loss.

- Backlash (the small amount of play between mechanical elements) reduces positioning accuracy.

- Maintenance requirements are higher due to component degradation over time.

- Limited speed and acceleration, as mechanical systems can only operate so fast before vibration and instability occur.

In environments where ultra-precise positioning or rapid, repeatable motion is essential, such as in CNC machining, laser cutting, or automated inspection, these limitations become costly and inefficient.

As a result, the demand for cleaner, faster, and more efficient motion control has driven industries to adopt linear motion drives as the modern standard for precision automation.

Key Advantages of Linear Motion Drives

The growing adoption of linear motion drives across industries is not just a technological trend, it’s a performance revolution. By replacing complex mechanical conversions with direct electromagnetic force, these systems unlock a new level of speed, precision, and reliability in modern automation.

Below are the five most significant advantages that make linear motion drives the preferred choice over traditional motion systems.

1. Higher Precision and Repeatability

One of the greatest strengths of a linear motion drive is its exceptional positioning accuracy. Because the motion is generated directly through electromagnetic interaction, there’s no mechanical backlash or slippage, two common issues in screw- or belt-driven systems.

This direct-drive mechanism allows the system to achieve micron-level precision with consistent repeatability, even during rapid acceleration or deceleration. For industries such as semiconductor fabrication, CNC machining, or optical inspection, this level of precision ensures higher product quality and reduced rejection rates.

2. Faster Acceleration and Smoother Motion

Unlike rotary systems that must convert rotational energy into linear movement, linear drives deliver force directly along the motion path. This eliminates inertia from mechanical linkages, allowing for rapid acceleration, higher top speeds, and smoother velocity profiles.

The result? Machines that respond faster, move more fluidly, and complete production cycles in less time, all while maintaining stability and accuracy. This makes linear motion drives a key enabler of high-speed automation in industries such as packaging, electronics, and robotics.

3. Greater Energy Efficiency

Every mechanical conversion in a traditional system from gears to belts, introduces energy losses due to friction and heat. Linear motion drives, on the other hand, operate on direct electromagnetic propulsion, converting electrical energy into linear force with minimal loss.

This higher efficiency translates into lower power consumption, less heat generation, and reduced operating costs over the system’s lifetime. For manufacturers aiming to meet sustainability targets and reduce their carbon footprint, linear motion drives represent a smarter, greener choice.

4. Low Maintenance and Long Lifespan

Because linear drives have fewer moving parts, there’s virtually no mechanical wear and tear. Components like ball screws, belts, or gearboxes which often require lubrication and periodic replacement are no longer needed.

This design not only extends the system’s operational life but also reduces downtime and maintenance costs. In continuous-production environments, the benefit is clear: maximum uptime and consistent performance without the need for frequent servicing.

5. Compact Design and High Flexibility

Linear motion drives can be configured in various layouts, horizontal, vertical, or even inverted depending on the application. Their slim, modular design allows for seamless integration into tight spaces and complex machinery, making them suitable for both retrofitting and new system designs.

In addition, their scalability means engineers can tailor stroke length, force output, and motor size to match specific process needs. This flexibility enables manufacturers to optimize productivity and space utilization without sacrificing performance.

By eliminating mechanical inefficiencies and focusing on direct electromagnetic motion, linear motion drives outperform traditional systems in nearly every critical aspect, speed, precision, durability, and efficiency. They represent the next stage in motion control evolution, helping industries achieve smarter, faster, and more sustainable automation.

Industrial Applications of Linear Motion Drives

As automation technology continues to advance, linear motion drives have become a crucial component in a wide range of industries. Their ability to deliver high precision, speed, and reliability makes them the foundation of next-generation machinery and production systems.

Here are some of the most impactful applications where linear motion drives are transforming industrial performance:

- Robotics and Pick-and-Place Systems: Enable smooth, synchronized movements for robotic arms, ensuring accurate placement, faster cycle times, and reduced vibration, key for assembly lines and material handling operations.

- CNC Machines and Laser Cutting: Provide direct, precise positioning for machining and cutting processes. This results in finer detailing, cleaner cuts, and consistent product quality across mass production runs.

- Semiconductor and Electronics Manufacturing: Ensure micron-level accuracy and contamination-free operation, essential in environments where precision and cleanliness determine product yield and reliability.

- Medical and Laboratory Equipment: Power precise, repeatable motion in imaging, diagnostics, and sample-handling systems. Their silent operation and compact design make them ideal for cleanroom and medical-grade equipment.

- Packaging and Inspection Systems: Deliver high-speed, continuous motion that enhances throughput and maintains stability during product packaging, labeling, and quality inspection tasks.

- Automated Warehousing and Transportation: Enable fast, efficient linear movement for automated storage and retrieval systems (AS/RS), conveyors, and smart logistics solutions.

Each of these applications benefits from the direct-drive precision, zero backlash, and maintenance-free design that only linear motion drives can provide.

ITG Linear Motor supports these diverse industries with advanced linear motion solutions designed for maximum efficiency, durability, and customization, helping businesses stay ahead in the era of smart manufacturing.

In short, whether it’s enabling the delicate precision of semiconductor production or driving the high-speed power of automated logistics, linear motion drives are the silent force behind the future of intelligent motion control.

ITG Linear Motor – Delivering Linear Motion Drives Performance

When you demand precision, speed, and reliability in motion control, you don’t settle for off-the-shelf solutions. You turn to specialists. ITG Linear Motor stands at the forefront of next-generation linear drive technology, engineering linear motion systems that redefine what “high performance” truly means.

At its core, ITG offers a comprehensive product family tailored for various industrial needs:

- Ironcore Linear Motors for high force density and robust thermal performance, ideal for heavy-duty automation like CNC, packaging, and assembly.

- Ironless Linear Motors, delivering ultra-smooth, cogging-free motion with minimal inertia, perfect for precision tasks in medical devices, metrology, or electronics manufacturing.

- Ironless Vacuum Linear Motors, designed specifically for cleanroom or vacuum environments, combining strong thrust and high stability under stringent conditions.

- Custom Linear Motors & OEM Solutions, allowing design flexibility from custom geometries, cable exit positions, to tailored magnetic paths, ensuring seamless integration into complex machine architectures.

- Torque Motors and related modules for when rotary precision or direct-drive torque control is needed as part of a hybrid motion system.

Why ITG Linear Motor Stands Out:

- Engineered for real-world challenges: Each motor is designed with deep attention to thermal management, magnetic efficiency, and mechanical robustness, so your machine performs consistently under heavy loads or continuous cycles.

- Zero compromises on precision: Thanks to direct-drive architecture and careful magnetic optimization, ITG motors deliver micron-level positioning, minimal cogging, and stable performance even at high velocity.

- Seamless adaptability: Whether you need long strokes, compact fits, or custom shapes, ITG’s modular approach lets you tailor the motor to exact specification, no overkill, no wasted capacity.

- Support from concept to deployment: ITG is not just a supplier, it aims to be your partner. From technical consultation and design support to system integration and after-sales service, they walk the journey with you.

Harnessing the full potential of linear motion drive technology demands not only understanding the principles but also partnering with a provider that delivers on performance, reliability, and flexibility. ITG Linear Motor does exactly that, giving engineers and manufacturers the tools to push the boundaries of motion control.

If you’re aiming to build or upgrade a motion system that thrives in high-speed automation, high-precision tasks, or tough environments, ITG’s linear motion drives are built to perform without compromise.

Conclusion

The shift from traditional motion systems to linear motion drives marks a defining moment in the evolution of industrial automation. As industries demand ever-greater levels of precision, speed, and reliability, the limits of mechanical conversion are giving way to the power of direct electromagnetic motion.

Linear motion drives don’t just move machines, they move entire production ecosystems toward smarter, faster, and more sustainable performance. From semiconductor fabrication to robotic assembly, their advantages are clear: unmatched precision, higher efficiency, lower maintenance, and design freedom that traditional systems can’t match.