Industrial motion systems are evolving beyond traditional mechanical drives as demands for higher speed, accuracy, and durability continue to increase. Linear Induction Motors (LIMs) enable direct linear motion through electromagnetic force, removing the need for complex transmission components while ensuring smooth, contactless operation. With their ability to deliver high thrust, rapid acceleration, and reliable performance in demanding environments, LIMs are increasingly adopted across industrial automation, transportation, and material handling systems. This article examines the performance characteristics and practical applications of Linear Induction Motors, providing a clear technical perspective for engineers and system integrators.

What Is a Linear Induction Motor?

A Linear Induction Motor (LIM) is an electric motor designed to produce direct linear motion instead of rotational movement. Unlike conventional induction motors that generate torque through a rotating shaft, a LIM creates thrust along a straight path using electromagnetic forces. This fundamental difference allows motion systems to operate without mechanical transmission elements such as gears, belts, ball screws, or lead screws.

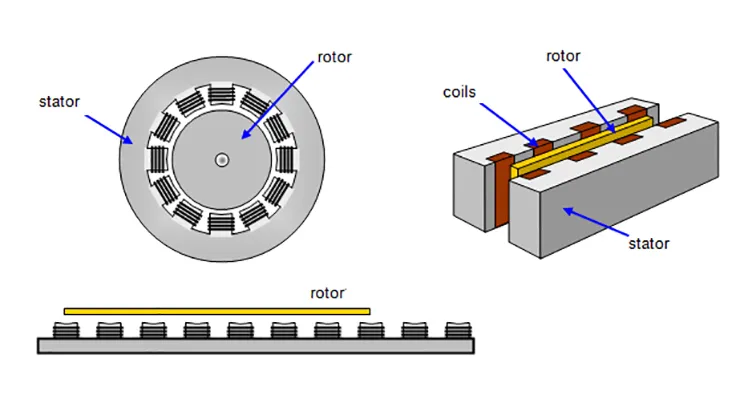

From a structural perspective, a Linear Induction Motor can be considered a “flattened” version of a traditional rotary induction motor. When the stator of a rotary motor is unrolled and laid out in a straight line, the result is a linear primary that generates a traveling magnetic field. This magnetic field interacts with a conductive secondary element, commonly referred to as a reaction plate, to produce linear force.

The LIM consists of two main components. The primary includes laminated iron cores and three-phase windings that generate the traveling magnetic field when energized. The secondary, typically made of aluminum or copper bonded to a steel backing plate, does not require electrical connections. As the magnetic field sweeps along the primary, it induces eddy currents in the secondary conductor. The interaction between these induced currents and the magnetic field creates a Lorentz force, which drives the secondary (or the primary, depending on system design) in a straight line.

One of the defining characteristics of a Linear Induction Motor is its contactless force generation. Since there is no physical contact between the moving and stationary components, mechanical wear is significantly reduced. This makes LIMs particularly suitable for applications requiring high speed, long stroke lengths, or operation in harsh environments where dust, moisture, or vibration would degrade conventional mechanical drive systems.

In practical terms, Linear Induction Motors are widely used in industrial automation, material handling, and transportation systems where simplicity, robustness, and dynamic performance are critical. By eliminating complex mechanical linkages, LIMs offer a streamlined approach to linear motion that balances performance, reliability, and system flexibility.

How Does a Linear Induction Motor Work?

A Linear Induction Motor (LIM) operates based on the same electromagnetic principles as a conventional rotary induction motor, with the key difference being that the generated force acts in a straight line rather than producing rotational torque. Its operation relies on the interaction between a traveling magnetic field and induced currents in a conductive secondary element.

When a three-phase alternating current is supplied to the windings of the LIM primary, it generates a traveling magnetic field that moves linearly along the length of the motor. The speed of this magnetic field, often referred to as the synchronous linear speed, is determined by the supply frequency and the pole pitch of the motor. This traveling field is the fundamental driver of motion in a LIM system.

As the magnetic field passes over the secondary reaction plate, it induces eddy currents within the conductive layer, typically made of aluminum or copper. According to electromagnetic induction principles, these induced currents create their own magnetic field, which opposes the original field generated by the primary. The interaction between the two magnetic fields results in a Lorentz force, producing thrust along the direction of the traveling magnetic field.

A critical parameter in LIM operation is slip, defined as the difference between the speed of the traveling magnetic field and the actual speed of the moving secondary. Slip is essential for force generation: without slip, no currents would be induced in the secondary, and no thrust would be produced. At higher slip values such as during startup or acceleration, the LIM can generate high thrust, while thrust decreases as the secondary speed approaches the synchronous speed.

The air gap between the primary and secondary also plays a significant role in LIM performance. A larger air gap reduces magnetic coupling and thrust but increases tolerance to mechanical misalignment and environmental contaminants. This trade-off is one reason Linear Induction Motors are well-suited for industrial environments where precision alignment is difficult or where dust and debris are present.

From a control standpoint, LIMs are commonly driven by variable frequency drives (VFDs) or specialized motion controllers. By adjusting the input frequency and current, engineers can precisely control thrust, speed, and acceleration. Although LIMs generally exhibit lower efficiency compared to linear synchronous motors, their simple structure, robust operation, and contactless force generation make them highly effective for many real-world applications.

In summary, a Linear Induction Motor converts electrical energy directly into linear mechanical motion through electromagnetic induction. By eliminating mechanical transmission elements, LIMs provide smooth, reliable, and high-dynamic motion that meets the demands of modern industrial and transportation systems.

Performance Characteristics of Linear Induction Motors

The performance characteristics of a Linear Induction Motor (LIM) reflect the unique advantages of electromagnetic direct-drive technology. By eliminating mechanical transmission elements, LIMs deliver linear motion that is highly dynamic, robust, and adaptable to a wide range of industrial conditions.

Understanding these performance aspects is essential for engineers and system designers when evaluating LIMs for real-world applications.

Thrust Force and Acceleration

Linear Induction Motors are capable of generating high thrust forces directly along the axis of motion, without relying on mechanical conversion mechanisms. Thrust is produced through the interaction between the traveling magnetic field and the induced eddy currents in the secondary conductor, allowing force to be applied smoothly and continuously across the entire stroke.

This direct force generation enables rapid acceleration and deceleration, making LIMs well suited for applications that require frequent starts, stops, and changes in speed. Unlike mechanical systems, LIMs do not suffer from backlash, compliance, or wear-related performance degradation over time.

Key characteristics related to thrust and acceleration include:

- High thrust density relative to motor size

- Fast dynamic response due to low moving inertia

- Smooth force output without mechanical vibration

- Consistent performance even under fluctuating loads

As a result, LIMs are commonly used in material handling, automated transport, and high-speed industrial motion systems where dynamic performance is critical.

Speed Capability and Dynamic Response

Linear Induction Motors offer excellent speed flexibility, particularly in long-stroke or continuous-motion applications. The linear speed of a LIM is determined by the frequency of the supplied current and the pole pitch of the primary, allowing precise electronic control over motion profiles.

Because LIMs do not rely on rotating components or mechanical transmissions, they can operate reliably at higher speeds where traditional systems would experience excessive wear or mechanical limitations. Speed changes are smooth and immediate, supporting high-throughput processes with minimal delay.

Typical speed-related advantages include:

- Wide controllable speed range

- Stable operation at both low and high speeds

- Rapid response to speed commands from the controller

- Reduced mechanical constraints at high velocities

These characteristics make LIMs particularly attractive for conveyor systems, sorting equipment, and transportation applications where consistent speed control is essential.

Positioning Accuracy and Motion Smoothness

While Linear Induction Motors are generally not designed for ultra-precision positioning, they deliver stable, repeatable, and smooth motion when integrated with appropriate feedback and control systems. The absence of mechanical contact eliminates stick-slip effects, backlash, and transmission-induced vibration.

Motion smoothness is one of the most valued attributes of LIMs, especially in applications involving continuous movement or sensitive payloads. With modern motion controllers and position sensors, LIM-based systems can achieve reliable positioning performance suitable for most industrial automation tasks.

Key factors influencing accuracy and smoothness include:

- Uniform electromagnetic force distribution

- No mechanical backlash or elastic deformation

- Reduced vibration and acoustic noise

- Compatibility with encoder-based feedback systems

For applications such as transfer lines, automated guided systems, and industrial handling equipment, this balance of smoothness and accuracy is often more advantageous than extreme precision.

Efficiency and Thermal Performance

Efficiency in Linear Induction Motors is influenced by electromagnetic design parameters such as slip, air gap size, and secondary material properties. Because LIMs rely on induced currents in the secondary conductor, eddy current losses are inherent, resulting in heat generation within the reaction plate.

Although LIMs may exhibit lower efficiency compared to linear synchronous motors, their thermal behavior is predictable and manageable. Proper system design, including duty cycle planning, cooling methods, and material selection, can significantly improve overall performance and reliability.

When these factors are addressed at the design stage, LIMs can operate efficiently and reliably even in demanding industrial environments.

Reliability and Maintenance Characteristics

One of the strongest performance advantages of Linear Induction Motors lies in their exceptional reliability and low maintenance requirements. With no mechanical contact between moving and stationary components, there is minimal wear, no lubrication requirements, and significantly fewer failure points compared to conventional drive systems.

This inherent simplicity translates into longer service life, reduced downtime, and lower total cost of ownership. LIMs are especially valuable in systems where continuous operation is required or where maintenance access is limited.

Reliability-related benefits include:

- No mechanical wear components

- High resistance to dust, moisture, and vibration

- Stable performance over long operational periods

- Reduced maintenance and lifecycle costs

These characteristics make Linear Induction Motors a preferred solution for harsh environments, heavy-duty applications, and automated systems that demand long-term operational stability.

Taken together, the performance characteristics of Linear Induction Motors highlight a technology optimized for dynamic motion, robustness, and operational simplicity. While efficiency and precision trade-offs exist, the advantages in speed, reliability, and maintenance make LIMs a practical and effective choice across many industrial and transportation applications.

Linear Induction Motor vs Other Linear Motor Technologies

When comparing a Linear Induction Motor (LIM) with other linear motion technologies, the most important distinction lies in the way force is generated and transmitted. Unlike mechanical drive systems or magnet-based linear motors, LIMs rely on electromagnetic induction to produce thrust, resulting in a contactless and highly robust motion solution. This fundamental principle directly influences performance, cost, and application suitability.

Compared to Linear Synchronous Motors (LSMs), Linear Induction Motors typically offer a simpler and more rugged structure. LSMs use permanent magnets on the secondary, enabling higher efficiency and superior positioning accuracy. However, this also increases system cost and sensitivity to environmental factors such as temperature, contamination, and magnetic interference. LIMs, by contrast, eliminate permanent magnets entirely, making them more tolerant of harsh industrial conditions and more economical for long-stroke or heavy-duty applications, even though their efficiency and precision may be lower.

When evaluated against traditional mechanical linear drive systems such as ball screws, belt drives, or rack-and-pinion mechanisms, the advantages of LIMs become even more apparent. Mechanical systems convert rotary motion into linear movement, introducing friction, backlash, and wear over time. LIMs generate force directly along the motion axis, reducing mechanical complexity and improving reliability, especially in high-speed or high-cycle environments.

From a practical engineering perspective, the differences between LIMs and other technologies can be summarized as follows:

- LIMs provide direct, contactless linear motion without mechanical transmission components

- LSMs deliver higher efficiency and precision but at a higher cost and complexity

- Mechanical drives offer high force at low speeds but require frequent maintenance and precise alignment

- LIMs are better suited for long travel distances and environments with dust, moisture, or vibration

Another key consideration is total cost of ownership. While the initial efficiency of LIMs may be lower than that of LSMs, the absence of permanent magnets and mechanical wear components often results in lower maintenance costs and longer service life. This makes Linear Induction Motors an attractive choice for applications where robustness, scalability, and operational continuity are more critical than ultra-high precision.

Overall, Linear Induction Motors occupy a distinct position among linear motion technologies. They bridge the gap between high-performance electromagnetic solutions and rugged industrial drive systems, offering a balanced combination of simplicity, durability, and dynamic capability. For many industrial and transportation applications, this balance makes LIMs a practical and cost-effective alternative to both magnet-based linear motors and conventional mechanical drives.

Applications of Linear Induction Motors

Linear Induction Motors are increasingly adopted across industries where traditional mechanical drive systems struggle to meet demands for speed, durability, and operational efficiency. Thanks to their contactless force generation and direct linear motion, LIMs offer a versatile solution capable of supporting both high-performance automation and large-scale industrial systems.

- Industrial automation and material handling systems benefit from Linear Induction Motors thanks to their ability to deliver smooth, high-speed linear motion without mechanical wear. LIMs are widely used in conveyor lines, transfer systems, and automated logistics where continuous operation, long travel distances, and minimal maintenance are critical.

- High-speed sorting and packaging equipment relies on the rapid acceleration and deceleration capabilities of LIMs. Their direct-drive nature allows precise control of motion profiles, improving throughput and reducing downtime in demanding production environments.

- Transportation and people mover systems utilize Linear Induction Motors for contactless propulsion and reliable performance over long distances. Applications include automated transit systems, shuttle platforms, and maglev-based solutions where durability, safety, and consistent thrust are essential.

- Manufacturing and assembly lines adopt LIMs for moving workpieces between stations with stable and repeatable motion. The absence of mechanical backlash ensures smooth transfer, which is especially valuable in electronics, automotive, and precision manufacturing processes.

- Harsh and industrial environments such as dusty factories, high-humidity facilities, or areas exposed to vibration benefit from the robust construction of Linear Induction Motors. With no mechanical contact and minimal sensitivity to contamination, LIMs maintain reliable operation where conventional drive systems may fail.

- Long-stroke and large-scale motion systems take advantage of the scalability of Linear Induction Motors. LIMs can be extended along long tracks without significant loss of performance, making them ideal for warehousing systems, large material transport platforms, and heavy-duty industrial applications.

- Special-purpose and custom motion solutions use LIM technology where flexibility and simplicity are required. From test rigs to specialized industrial machinery, LIMs provide engineers with a versatile linear motion solution that can be adapted to unique performance and environmental requirements.

Taken together, these applications highlight the adaptability of Linear Induction Motors across a broad spectrum of industries. Whether the priority is high-speed automation, long-distance transport, or reliable operation in harsh conditions, LIM technology delivers a balanced combination of performance, robustness, and system simplicity, making it a practical choice for modern linear motion challenges.

Conclusion

Linear Induction Motors represent a practical and forward-looking solution for modern motion systems, combining direct linear drive, robust performance, and minimal mechanical complexity. By understanding their operating principles, performance characteristics, and real-world applications, engineers and system designers can confidently evaluate where LIM technology delivers the greatest value. As industrial automation and transportation systems continue to evolve, Linear Induction Motors will play an increasingly important role in enabling reliable, scalable, and high-dynamic linear motion solutions.