As modern industries push toward ever-higher levels of automation and precision, the demand for motion systems capable of nanometer-level accuracy has never been greater. From semiconductor manufacturing and optical alignment to medical and scientific instruments, conventional linear actuation technologies are often pushed beyond their physical limits. This is where piezo linear actuators emerge as a powerful alternative.

By leveraging the piezoelectric effect to generate direct, friction-minimized linear motion, these actuators deliver exceptional positioning accuracy, ultra-fast response times, and compact form factors, making them indispensable in applications where precision is non-negotiable. In this article by ITG, we explore what piezo linear actuators are, how they are structured, and the key advantages that set them apart in high-precision motion control systems.

What Are Piezo Linear Actuators?

Piezo linear actuators are precision motion devices that generate linear displacement by exploiting the piezoelectric effect, a physical phenomenon in which certain materials deform when an electric voltage is applied. Unlike conventional actuation technologies that rely on electromagnetic fields, rotating components, or mechanical transmissions, piezo linear actuators produce motion through direct material deformation, enabling an exceptionally high level of accuracy and repeatability.

At their core, piezo linear actuators convert electrical energy into controlled, microscopic mechanical movement. When voltage is applied to a piezoelectric element, typically a ceramic material, the element expands or contracts along a specific axis. Although this deformation is extremely small, often measured in micrometers or nanometers, it can be precisely controlled and repeatedly generated at very high speeds. Through mechanical amplification or incremental motion mechanisms, this tiny deformation is transformed into usable linear motion.

What fundamentally distinguishes piezo linear actuators from traditional linear motors, ball screw systems, or pneumatic actuators is their motion generation principle. Piezo-based systems do not require gears, belts, or rotary-to-linear conversion. As a result, they eliminate backlash, minimize friction, and significantly reduce mechanical wear. This direct-drive characteristic allows piezo linear actuators to achieve sub-micron positioning resolution and maintain stable performance over long operating lifetimes.

Piezo linear actuators are particularly valued in applications where precision outweighs travel length. While their stroke is generally shorter than that of electromagnetic linear motors, they excel in environments that demand ultra-fine positioning, fast dynamic response, and consistent force output. Industries such as semiconductor fabrication, optical system alignment, medical instrumentation, and precision metrology rely on piezo linear actuators to perform tasks that would be difficult or impossible with conventional actuation technologies.

In essence, piezo linear actuators represent a specialized class of linear motion solutions designed for high-precision, high-reliability positioning. Understanding what they are, and how they fundamentally differ from other linear actuation technologies, is the first step toward selecting the most effective motion system for advanced industrial and scientific applications.

Basic Structure of a Piezo Linear Actuator

To fully understand how piezo linear actuators achieve such high levels of precision and repeatability, it is essential to examine their fundamental structure. Although designs may vary depending on stroke length, force requirements, and control strategy, most piezo linear actuators share a common set of core components that work together to convert electrical input into highly controlled linear motion.

1. Piezoelectric Element

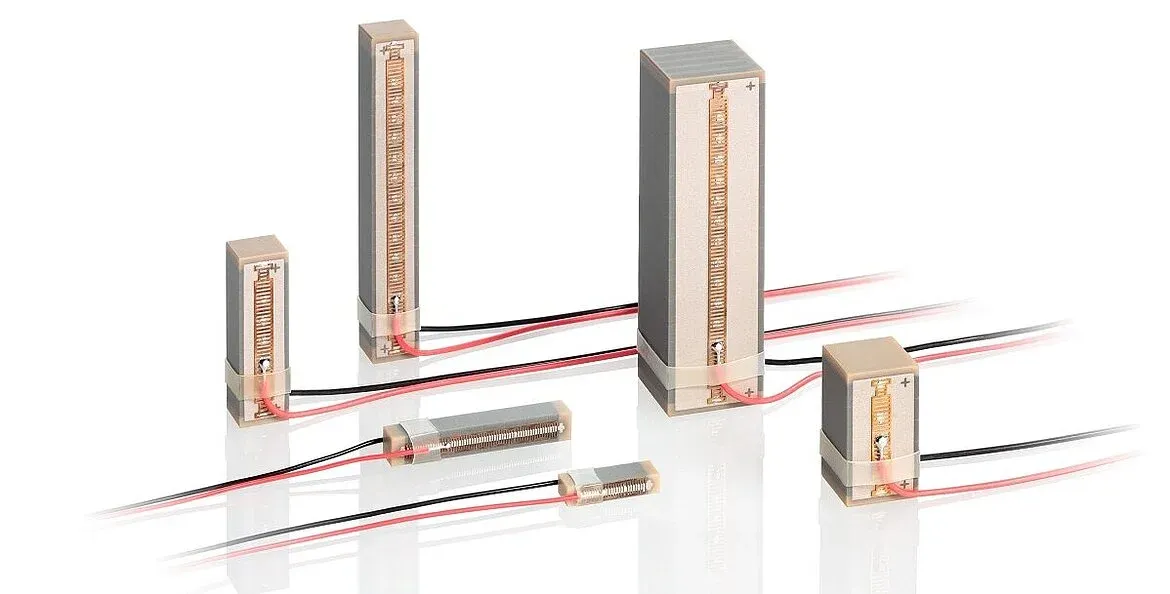

The piezoelectric element is the heart of a piezo linear actuator. It is typically made from piezoelectric ceramic materials that deform when an electrical voltage is applied. This deformation occurs along a defined axis and can be precisely controlled by adjusting the input voltage.

While the absolute displacement of a single piezo element is extremely small, often in the micrometer or nanometer range, it is highly repeatable and capable of responding at very high frequencies.

In industrial-grade piezo linear actuators, multiple piezo layers are often stacked to increase displacement and force output. This stacked configuration allows the actuator to deliver high blocking force while maintaining exceptional positioning resolution, making it suitable for demanding precision applications.

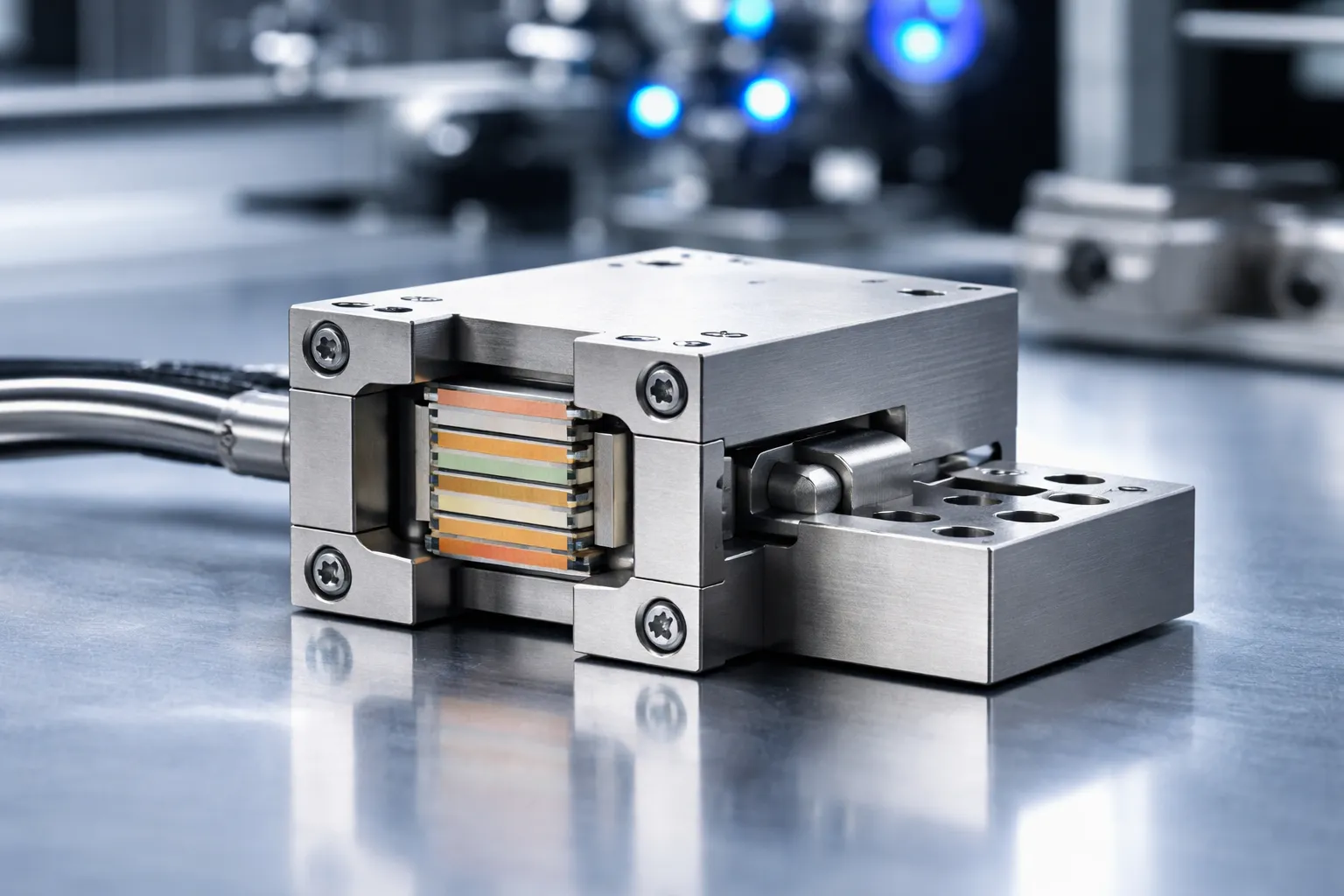

2. Mechanical Amplification or Motion Mechanism

Because the raw displacement of a piezoelectric element is limited, most piezo linear actuators incorporate a mechanical mechanism to transform or amplify motion into usable linear travel. Common approaches include flexure-based amplification systems, stick-slip mechanisms, and inchworm-style designs.

Flexure mechanisms increase stroke length while preserving stiffness and accuracy, whereas stick-slip and inchworm mechanisms enable incremental motion over longer travel distances by combining rapid piezo deformation with controlled friction. The choice of mechanism directly influences the actuator’s stroke, speed, load capacity, and positioning stability.

3. Linear Guide and Motion Transmission

To ensure smooth and accurate linear movement, piezo linear actuators are equipped with a guiding structure that constrains motion along a single axis. This may take the form of precision flexures, linear bearings, or integrated guide rails, depending on the actuator design.

The guiding system plays a critical role in maintaining alignment, minimizing parasitic motion, and preserving long-term accuracy. High-quality linear guidance also reduces mechanical stress on the piezoelectric element, contributing to improved reliability and service life.

4. Driving Electronics and Control Interface

Piezo linear actuators require dedicated driving electronics to supply the high-voltage, low-current signals needed to activate the piezoelectric element. These drivers convert standard control signals into precisely regulated voltage waveforms, enabling fine control over displacement and force.

In advanced systems, closed-loop control is implemented using position sensors such as strain gauges, capacitive sensors, or encoders. Feedback allows the actuator to compensate for non-linearities, temperature effects, and load variations, ensuring stable and accurate positioning in real-world operating conditions.

Together, these structural components form a tightly integrated motion system capable of delivering ultra-precise linear movement. By combining direct piezoelectric actuation with carefully engineered mechanical and electronic subsystems, piezo linear actuators achieve a level of performance that is difficult to match with conventional linear motion technologies.

Key Advantages of Piezo Linear Actuators

Piezo linear actuators are widely adopted in high-precision industries not by coincidence, but because they offer a unique set of performance advantages that conventional linear actuation technologies struggle to achieve. Below are the key benefits that make piezo linear actuators a preferred choice for ultra-precision motion control applications.

- Ultra-high positioning accuracy and resolution: Capable of achieving positioning resolutions down to the nanometer level, piezo linear actuators enable extremely fine motion control without backlash or hysteresis associated with mechanical transmission systems. This makes them ideal for applications where even the smallest positional error is unacceptable.

- Fast response time and high dynamic performance: By relying on direct material deformation rather than electromagnetic or mechanical inertia, piezo linear actuators respond almost instantaneously to control signals. Their microsecond-level response time allows for rapid positioning, vibration compensation, and dynamic motion profiles.

- Compact size with high force density: Piezoelectric materials can generate high force output within a very small footprint. This compact design enables system engineers to integrate high-performance linear motion into space-constrained equipment without sacrificing precision or stability.

- No backlash and minimal mechanical wear: Since piezo linear actuators do not depend on gears, belts, or rotary-to-linear conversion, they inherently eliminate backlash. Reduced friction and contact points also translate into lower wear, resulting in consistent performance over long operational lifetimes.

- Electromagnetic interference–free operation: Piezo linear actuators operate without generating electromagnetic fields, making them highly suitable for sensitive environments such as optical systems, medical devices, and scientific instruments where EMI can compromise system performance.

- High reliability and low maintenance requirements: The simplified mechanical structure and absence of traditional moving parts reduce failure points and maintenance needs. As a result, piezo linear actuators deliver reliable, repeatable motion even in continuous or high-duty-cycle applications.

In summary, the advantages of piezo linear actuators lie in their ability to deliver unmatched precision, speed, and reliability within a compact form factor. These strengths make them an essential motion technology for applications that demand absolute accuracy and long-term performance, while also highlighting why they are often evaluated alongside linear motors when designing advanced motion control systems.

Typical Applications Requiring These Advantages

The unique performance characteristics of piezo linear actuators make them especially valuable in applications where extreme precision, fast response, and long-term stability are essential. Below are some of the most common industrial and scientific use cases that rely on the advantages of piezo linear actuation.

- Semiconductor manufacturing and inspection equipment: Piezo linear actuators are widely used in wafer positioning, mask alignment, and lithography systems, where nanometer-level accuracy and rapid positioning directly impact yield and process stability.

- Optical alignment and photonics systems: In optical benches, laser alignment modules, and interferometric measurement systems, piezo linear actuators enable ultra-fine adjustments without introducing vibration or electromagnetic interference.

- Medical and life science instruments: Applications such as micro-dosing devices, imaging systems, and laboratory automation rely on piezo linear actuators for their clean operation, high repeatability, and precise control of small movements.

- Precision metrology and measurement systems: Coordinate measuring machines (CMMs), surface profilers, and nano-positioning stages use piezo linear actuators to achieve stable, repeatable positioning essential for high-accuracy measurements.

- Micro-positioning stages in industrial automation: In advanced automation and robotics, piezo linear actuators support fine positioning tasks such as component alignment, calibration, and vibration compensation, where conventional actuators lack sufficient resolution.

- Research and scientific instrumentation: Piezo linear actuators are commonly found in microscopy systems, experimental physics setups, and academic research equipment, where controlled micro-motion is critical to experimental accuracy.

Overall, these applications demonstrate where piezo linear actuators deliver the greatest value: environments that demand ultra-precision, fast dynamic response, and consistent performance over time. Understanding these use cases also helps engineers determine when piezo linear actuators are the optimal choice, and when alternative motion technologies such as linear motors may be better suited for longer travel or higher-speed applications.

Conclusion

Piezo linear actuators represent a highly specialized motion technology designed to meet the most demanding requirements of modern precision engineering. By leveraging the piezoelectric effect, these actuators deliver exceptional positioning accuracy, fast dynamic response, compact design, and long-term reliability, capabilities that conventional linear actuation technologies often struggle to achieve. Their unique structure and performance advantages make them indispensable in applications where precision, stability, and repeatability are critical to system success.

However, understanding piezo linear actuators is not only about recognizing their strengths, but also about knowing when they are the right solution. While they excel in ultra-precision, short-stroke, and high-stability applications, other technologies such as electromagnetic linear motors, may be better suited for longer travel distances, higher speeds, or heavier payloads. Selecting the optimal motion system therefore requires a clear understanding of application requirements and performance priorities.