In modern industrial systems, accurate current measurement plays a critical role in ensuring efficiency, safety, and precise control. From motor drives and automation equipment to power electronics and motion control systems, engineers rely on reliable sensing technologies to monitor electrical performance in real time. Among the available solutions, the Hall effect current sensor has become one of the most widely adopted methods thanks to its non-contact operation, electrical isolation, and ability to measure both AC and DC currents with high stability. In this article by ITG, we explore what a Hall effect current sensor is, how it works, its key advantages, and why it has become an essential component in a wide range of industrial applications.

What Is a Hall Effect Current Sensor?

A Hall effect current sensor is an electronic device used to measure electric current by detecting the magnetic field generated around a current-carrying conductor. Instead of making direct electrical contact with the circuit, the sensor relies on the Hall effect phenomenon, allowing it to measure current in a safe, isolated, and non-intrusive manner.

Unlike traditional current sensing methods such as shunt resistors that require physical insertion into the circuit, a Hall effect current sensor measures current indirectly. When current flows through a conductor, it creates a proportional magnetic field. The sensor detects this magnetic field and converts it into an electrical signal that accurately represents the magnitude and direction of the current.

One of the defining characteristics of a Hall effect current sensor is its ability to provide galvanic isolation between the measured current path and the output signal. This isolation significantly improves system safety and protects sensitive control electronics, especially in high-voltage and high-current industrial environments.

Hall effect current sensors are widely used to measure both alternating current (AC) and direct current (DC). This versatility makes them suitable for a broad range of applications, including motor drives, power converters, automation systems, and advanced motion control technologies such as linear motors and servo systems.

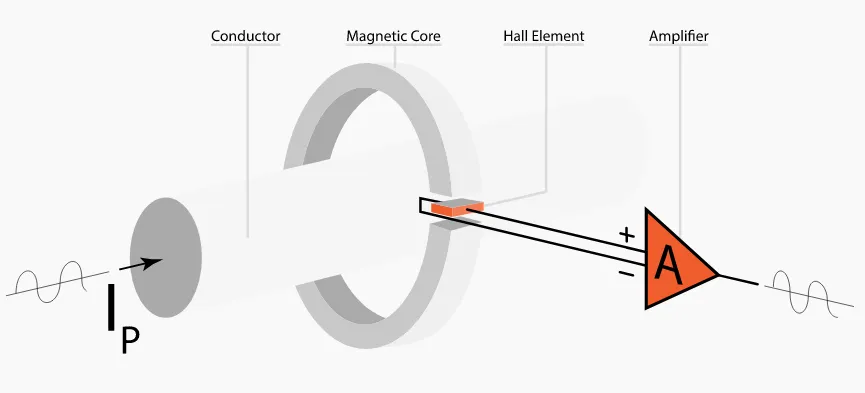

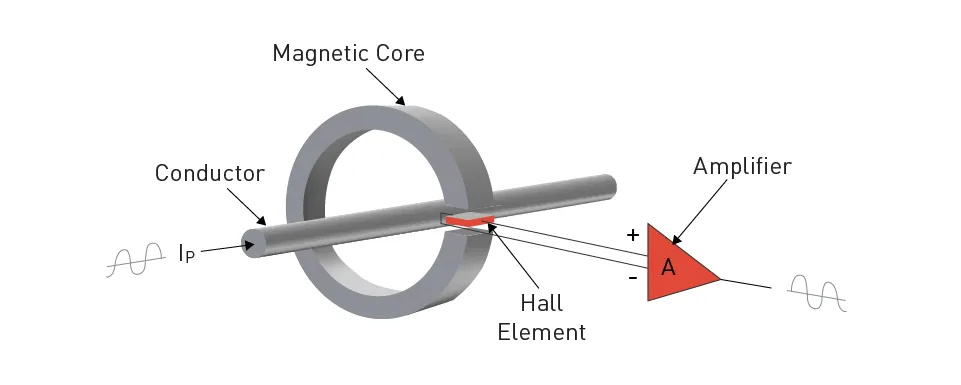

From a structural perspective, a typical Hall effect current sensor consists of a magnetic core or current conductor, a Hall sensing element, and signal conditioning circuitry. The Hall element responds to changes in the magnetic field caused by current variations, while the internal electronics process and amplify the signal to produce a stable and usable output, either analog or digital.

Thanks to their non-contact operation, electrical isolation, wide current measurement range, and reliable performance, Hall effect current sensors have become a preferred solution for modern industrial current sensing, particularly in applications where precision, safety, and long-term stability are essential.

How Does a Hall Effect Current Sensor Work?

A Hall effect current sensor operates by converting the magnetic field generated by an electric current into a proportional electrical signal. This process allows the sensor to measure current accurately without direct electrical contact with the conductor, ensuring both safety and reliability in industrial environments.

1. Magnetic Field Generation by Electric Current

When an electric current flows through a conductor, it produces a magnetic field around it according to Ampère’s law. The strength of this magnetic field is directly proportional to the magnitude of the current. In a Hall effect current sensor, the conductor carrying the current is either routed through a magnetic core or positioned close to a Hall sensing element to ensure precise magnetic field detection.

2. Detection of the Magnetic Field by the Hall Element

At the core of the sensor is a Hall element, a semiconductor device that responds to magnetic fields. When exposed to the magnetic field generated by the current, the Hall element produces a small voltage, known as the Hall voltage. This voltage is proportional to the magnetic flux density and, therefore, to the current flowing through the conductor.

3. Conversion into an Electrical Output Signal

The Hall voltage generated by the sensing element is typically very small and requires amplification. Internal signal conditioning circuits amplify, filter, and linearize the signal to produce a stable output. Depending on the sensor design, the output may be:

- An analog voltage proportional to the measured current

- An analog current output for industrial control systems

- A digital signal for monitoring and protection applications

This processed signal can then be sent to controllers, motor drives, or monitoring systems for real-time analysis and control.

4. Open-Loop and Closed-Loop Measurement Methods

Hall effect current sensors are commonly categorized into open-loop and closed-loop designs:

- Open-loop Hall effect current sensors directly measure the magnetic field produced by the current. They offer a simple structure, low power consumption, and cost-effective solutions for many general-purpose applications.

- Closed-loop (zero-flux) Hall effect current sensors use a compensation coil to counteract the magnetic field generated by the measured current. By maintaining a near-zero magnetic flux in the core, closed-loop sensors achieve higher accuracy, faster response times, and improved temperature stability, making them ideal for high-precision motor control and motion systems.

5. Electrical Isolation and Safety

Because the measurement is based on magnetic coupling rather than direct electrical contact, Hall effect current sensors provide inherent electrical isolation between the primary current path and the output signal. This isolation is particularly important in high-voltage motor drives, power electronics, and industrial automation systems, where protecting sensitive electronics and ensuring operator safety are critical.

6. Real-Time Current Measurement for Dynamic Systems

Thanks to their fast response and ability to measure both AC and DC currents, Hall effect current sensors are well suited for dynamic applications such as servo drives, linear motors, and motion control systems. Real-time current feedback enables precise torque control, improved efficiency, and enhanced system reliability.

Key Advantages of Hall Effect Current Sensors

The growing adoption of Hall effect current sensors across industrial systems is driven by their ability to deliver accurate, reliable, and safe current measurement in demanding operating conditions. Compared to conventional sensing methods, these sensors offer a combination of performance and flexibility that makes them particularly well suited for modern motor control and automation applications.

- Non-contact current measurement: Measures current indirectly through the magnetic field generated by the conductor, eliminating physical contact with the electrical circuit. This reduces wear, avoids power loss, and improves long-term reliability.

- Electrical isolation for enhanced safety: Provides galvanic isolation between the high-power current path and low-voltage control electronics, protecting sensitive components and ensuring safe operation in high-voltage industrial environments.

- Ability to measure both AC and DC currents: Unlike many traditional sensing methods, Hall effect current sensors can accurately measure alternating and direct currents, making them highly versatile for modern power and motion control systems.

- Wide current measurement range: Capable of measuring currents from a few milliamps to several kiloamps, making them suitable for applications ranging from precision control to heavy industrial machinery.

- Fast response time for dynamic systems: Delivers real-time current feedback, which is essential for high-speed motor control, servo systems, and linear motion applications where rapid current changes must be accurately tracked.

- Low power loss and minimal heat generation: Since the sensor does not rely on resistive elements in the current path, it introduces negligible insertion loss and avoids excessive heat buildup.

- High accuracy and stable performance: Modern Hall effect current sensors offer excellent linearity, low offset drift, and consistent performance across wide temperature ranges, ensuring reliable measurements over time.

- Compact design and easy integration: Available in various form factors, these sensors can be easily integrated into motor drives, power modules, and control cabinets without complex circuit modifications.

- Robust operation in harsh industrial environments: Designed to withstand vibration, electrical noise, and temperature fluctuations, making them ideal for industrial automation and motion control systems.

- Improved system efficiency and diagnostics: Accurate current feedback enables better control algorithms, energy optimization, fault detection, and predictive maintenance in advanced industrial applications.

Taken together, these advantages explain why Hall effect current sensors have become a preferred choice in modern industrial systems. Their combination of safety, precision, and versatility makes them especially valuable in high-performance motion control applications, where reliable current feedback is essential for achieving optimal system efficiency and long-term stability.

Common Industrial Applications of Hall Effect Current Sensors

Hall effect current sensors are widely used across industrial sectors where precise, real-time current measurement is essential for control, protection, and efficiency. Their non-contact operation, electrical isolation, and ability to measure both AC and DC motor currents make them a reliable solution for a broad range of demanding applications.

- Motor control and drive systems: Used in servo motors, linear motors, BLDC motors, and induction motor drives to provide accurate current feedback for torque control, speed regulation, and system stability.

- Motion control and automation systems: Enable precise monitoring of actuator and drive currents in automated production lines, improving positioning accuracy, repeatability, and overall system performance.

- Industrial robotics: Support real-time current measurement in robotic joints and arms, helping optimize motion profiles, detect overload conditions, and enhance operational safety.

- Power electronics and inverter systems: Applied in AC/DC converters, DC/DC converters, and inverters to monitor switching currents, improve efficiency, and protect power components from overcurrent events.

- Renewable energy and energy storage systems: Used in solar inverters, wind power systems, and battery management systems to measure charge and discharge currents with high reliability and electrical isolation.

- Electric and hybrid vehicle systems: Monitor traction motors, onboard chargers, and power distribution units, ensuring efficient energy usage and safe operation under high-current conditions.

- Industrial machinery and CNC equipment: Provide accurate current feedback for spindles, drives, and auxiliary systems, enabling better process control and predictive maintenance.

- Overcurrent protection and fault detection: Integrated into protection circuits to detect abnormal current conditions early, helping prevent equipment damage and reduce system downtime.

- High-precision motion systems: Essential in applications requiring fast dynamic response and tight control tolerances, such as linear motor stages and advanced motion platforms.

Together, these applications highlight the critical role of Hall effect current sensors in modern industrial environments. By delivering accurate, isolated, and real-time current information, they enable higher efficiency, improved reliability, and greater control in complex systems ranging from automation and robotics to advanced motion control solutions.

How to Select the Right Hall Effect Current Sensor

Selecting the right Hall effect current sensor is a critical step in ensuring accurate measurement, reliable system performance, and long-term operational stability. Because industrial applications vary widely in current levels, environmental conditions, and control requirements, careful evaluation of key parameters is essential before making a final decision.

1. Define the Required Current Range and Type

The first step in sensor selection is understanding the current that needs to be measured. This includes both the expected operating range and the maximum possible current under fault or overload conditions.

Hall effect current sensors are capable of measuring both AC and DC currents, making them suitable for motor drives, power converters, and motion control systems. However, choosing a sensor with an appropriate measurement range is crucial to maintain accuracy and avoid saturation. A sensor that is too small may saturate under peak loads, while an oversized sensor may reduce resolution at lower current levels.

Clearly defining the current range ensures stable measurements and forms the foundation for all other selection criteria.

2. Consider Accuracy, Bandwidth, and Response Time

Accuracy requirements depend heavily on the application. High-precision motion control systems such as servo drives and linear motors, demand accurate and fast current feedback to maintain precise torque and position control.

Bandwidth and response time are equally important in dynamic systems where current changes rapidly. Sensors with higher bandwidth can capture fast current transients more accurately, enabling better control performance and improved system stability.

Balancing accuracy, bandwidth, and response time ensures that the sensor can meet the performance demands of both steady-state and dynamic operating conditions.

3. Choose Between Open-Loop and Closed-Loop Designs

One of the most important design choices is selecting between open-loop and closed-loop (zero-flux) Hall effect current sensors.

Open-loop sensors offer a simple structure, low power consumption, and cost-effective solutions for many general industrial applications. Closed-loop sensors, on the other hand, provide higher accuracy, better linearity, faster response, and improved temperature stability.

For applications requiring high precision and long-term stability such as advanced motor control and motion systems, closed-loop sensors are often the preferred choice. Understanding this trade-off helps align sensor performance with system requirements.

4. Evaluate Electrical Isolation and Environmental Conditions

Electrical isolation is a key advantage of Hall effect current sensors, especially in high-voltage and high-power applications. The required isolation voltage should be carefully matched to the system’s electrical architecture to ensure safety and regulatory compliance.

Environmental factors such as temperature range, vibration, electromagnetic interference (EMI), and humidity also play a significant role in sensor performance. Selecting a sensor designed to withstand harsh industrial conditions helps maintain measurement accuracy and reliability over time.

Proper evaluation of isolation and environmental requirements minimizes risk and improves system durability.

5. Assess Integration, Form Factor, and System Compatibility

Finally, practical considerations such as physical size, mounting options, and electrical interface should not be overlooked. The sensor must fit within the available space and integrate smoothly with existing control electronics, such as motor drives or PLCs.

Output type: analog voltage, analog current, or digital should be compatible with the control system’s input requirements. Ease of integration reduces development time and helps ensure consistent performance across the entire system.

Careful attention to integration and compatibility simplifies system design and supports long-term maintainability.

Choosing the right Hall effect current sensor requires a balanced evaluation of electrical performance, environmental conditions, and system integration needs. By clearly defining current requirements, understanding accuracy and response demands, selecting the appropriate sensor architecture, and considering practical integration factors, engineers can ensure reliable and precise current measurement.

A well-selected Hall effect current sensor not only improves measurement accuracy but also enhances overall system efficiency, safety, and performance, especially in demanding industrial and motion control applications.

Conclusion

Hall effect current sensors have become an essential component in modern industrial systems, offering a reliable and efficient solution for accurate current measurement. By leveraging the Hall effect principle, these sensors enable non-contact, electrically isolated measurement of both AC and DC currents, addressing the growing demands for safety, precision, and performance in today’s industrial environments.

Throughout this article, we have explored what a Hall effect current sensor is, how it works, its key advantages, and the wide range of industrial applications it supports. From motor drives and power electronics to automation and advanced motion control systems, Hall effect current sensors play a critical role in ensuring stable operation, fast response, and long-term system reliability.