Choosing the right high torque DC motor can make or break the performance of your entire system. With countless specifications, motor types, and application demands to consider, the selection process often feels overwhelming, even for experienced engineers. This guide simplifies everything. From understanding torque requirements to evaluating environmental conditions and motor efficiency, you’ll learn exactly how to pinpoint the motor that delivers maximum power, reliability, and long-term value for your application. Let’s break down the essentials and help you make a confident, future-proof choice.

What Are High Torque DC Motors?

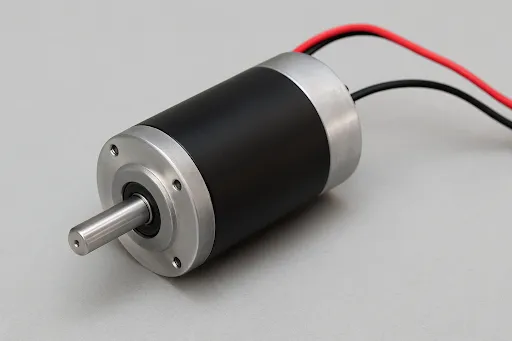

High torque DC motors are specially engineered electric motors designed to deliver a significantly higher rotational force (torque) compared to standard DC motors of similar size. Torque is the force that causes an object to rotate, and in industrial applications, it directly determines a motor’s ability to move, lift, push, or drive loads with strength and stability. Because of this, high torque DC motors are essential in systems that require powerful startup force, consistent load handling, or precise motion control under heavy demands.

Unlike conventional motors that prioritize speed over torque, high torque DC motors optimize their internal construction, including winding configuration, magnetic field strength, rotor design, and gear ratios to generate strong rotational output even at low speeds. This makes them ideal for applications where maintaining control under pressure is more important than achieving maximum RPM.

Definition and Core Characteristics

High torque DC motors are defined by their ability to provide strong torque output relative to their size and voltage input. They typically feature:

- Enhanced magnetic design for increased torque density.

- Robust winding architecture that supports higher current without overheating.

- Stable low-speed performance, essential for heavy-load operations.

- Precise controllability, especially when paired with modern motor drivers or servo systems.

These characteristics make them a preferred choice for applications where accuracy, force, and reliability need to coexist.

How High Torque DC Motors Work

The operating principle of a high torque DC motor is based on the interaction between electric current and magnetic fields. When current flows through the windings, it creates a magnetic force that pushes against the permanent magnets or electromagnets inside the motor, generating rotation. High torque variants maximize this force through:

- Higher current flow, increasing electromagnetic strength.

- Stronger permanent magnets, often utilizing materials like neodymium.

- Optimized rotor geometry for better mechanical leverage.

- Integrated gear mechanisms in some models to multiply torque output.

As a result, these motors can produce powerful rotational force at startup, maintain torque under heavy loads, and operate efficiently across a wide range of speeds.

Key Factors to Consider When Choosing a High Torque DC Motor

Selecting the right high torque DC motor is not simply a matter of choosing the most powerful option available, it requires a careful evaluation of performance needs, system constraints, environmental conditions, and long-term reliability.

Making the right choice ensures optimal efficiency, prevents premature motor failure, and guarantees smooth operation throughout your application’s lifecycle. Below are the essential factors every engineer, integrator, or system designer should analyze before making a final decision.

1. Required Torque and Speed Range

The first and most critical step is determining the exact torque and speed your application demands. A motor’s ability to deliver continuous torque (the torque it can sustain over long periods) versus peak torque (short bursts for startup or sudden load increases) must be aligned with the load profile of your system.

Understanding the speed–torque curve is equally important. High torque DC motors typically provide strong output at lower speeds, but choosing the wrong model may result in sluggish performance or overload during operation. By evaluating motion patterns, startup loads, acceleration needs, and potential resistance, you can select a motor that performs reliably without being oversized.

2. Power Requirements and Voltage Compatibility

Every high torque DC motor requires an appropriate power supply. The motor’s rated voltage should match the system’s available voltage to ensure consistent performance and prevent issues like overheating, under-speed operation, or excessive current draw.

Higher torque motors often require higher current, so it’s essential to verify that the power source and controller can handle the required amperage without voltage drops. Proper matching prevents damage to electronic components and ensures the motor operates within safe limits.

3. Motor Size and Mounting Constraints

High torque performance does not always mean bulky hardware. Modern motor designs can deliver significant torque in compact form factors, but only if the dimensions and mounting options fit your system. Before selecting a model, consider:

- Installation space

- Shaft size and orientation

- Mounting holes and bracket compatibility

- Weight and balance within the mechanical structure

Ensuring proper mechanical integration avoids misalignment, vibration, and long-term reliability issues.

4. Operating Environment

Environmental conditions have a major influence on motor longevity and stability. Factors such as temperature, humidity, dust, vibration, and exposure to chemicals can significantly impact motor performance. Look for features like:

- IP ratings (e.g., IP54, IP65) for dust and water protection

- Thermal protection to prevent overheating

- Corrosion-resistant materials for harsh industrial environments

- Insulation class ratings for electrical safety

Matching the motor’s specifications to the operating environment minimizes downtime and maintenance costs.

5. Efficiency and Heat Dissipation

High torque motors generate more heat due to increased current and mechanical load. Therefore, efficiency plays a key role in selecting the right model. A more efficient motor reduces power consumption, minimizes heat buildup, and extends the motor’s lifespan.

Depending on your application, consider whether the motor requires:

- Passive cooling (natural heat dissipation)

- Forced-air cooling using fans

- Liquid cooling for extremely high-power, continuous-duty systems

A well-managed thermal strategy ensures stable long-term operation under demanding conditions.

6. Duty Cycle and Motor Lifespan

Another crucial factor is the motor’s duty cycle, which measures how long it runs versus how long it rests. Applications requiring continuous operation need motors designed for 100% duty cycle, while intermittent operations allow for lower duty cycles.

Additionally, internal components such as bearings, brushes, commutators, and windings play a direct role in maintenance intervals and expected service life. Brushless models often offer significantly longer lifespans, higher efficiency, and lower maintenance requirements.

Types of High Torque DC Motors and Their Uses

High torque DC motors come in several configurations, each designed to deliver strong rotational force but optimized for different performance requirements, efficiency levels, and application environments.

Understanding the distinctions between these motor types is essential for choosing the right solution, whether you need smooth low-speed control, long-term durability, or maximum torque in compact spaces. Below are the most common types of high torque DC motors and where they are most effectively used.

1. Brushed High Torque DC Motors

Brushed DC motors are one of the most traditional and widely used motor types due to their simple construction and strong starting torque. They operate using brushes and a commutator that physically switch the current flow inside the motor, creating continuous rotation.

Advantages:

- Excellent initial torque output

- Straightforward control using basic drivers

- Cost-effective and easy to maintain

- Highly compatible with low-speed, high-load systems

Limitations:

- Brushes wear over time, requiring periodic maintenance

- Lower efficiency compared to brushless motors

- Generates more noise and heat

Typical Uses: Brushed high torque DC motors are ideal for applications where simplicity and strong startup power matter more than long-term efficiency, such as small machinery, conveyor systems, adjustable seats, portable tools, and low-voltage industrial equipment.

2. Brushless High Torque DC Motors (BLDC)

Brushless DC motors replace mechanical brushes with electronic commutation, resulting in smoother operation, higher efficiency, and significantly longer lifespan. BLDC motors are increasingly favored in both industrial and consumer applications where precision and reliability are essential.

Advantages:

- High torque density with excellent efficiency

- Quiet and smooth performance

- Minimal maintenance requirements

- Longer operational life due to brushless design

- Great for continuous-duty tasks

Limitations:

- Requires more advanced motor controllers

- Higher initial cost

Typical Uses: BLDC high torque motors are commonly used in robotics, medical equipment, industrial automation, drones, electric vehicles, and CNC machinery, where stability and long-term reliability are critical.

3. Gear Motors for High Torque Applications

Gear motors combine a DC motor with a gearbox to increase torque output significantly while reducing speed. By using gear systems such as spur, planetary, or worm gears, these motors multiply torque without requiring a larger motor body.

Advantages:

- Extremely high torque output in compact designs

- Wide range of gear ratios available

- Can operate efficiently at very low speeds

- Improved mechanical advantage for heavy loads

Limitations:

- Lower maximum speed

- Gear wear may require maintenance depending on load and materials

Typical Uses: High torque gear motors are essential in systems requiring powerful motion at controlled speeds, such as automated gates, industrial lifts, smart logistics systems, medical positioning devices, packaging machinery, and robotics with heavy payloads.

How to Match High Torque DC Motors to Your Application

Matching a high torque DC motor to your application is all about understanding what your system truly needs and ensuring every specification aligns with real operating conditions. The points below will help you make a confident and accurate selection.

- Identify the required torque, including both continuous torque for stable operation and peak torque for startup or sudden load changes. This determines whether the motor can handle your system effectively.

- Evaluate the type of load your application involves, such as constant load, variable load or shock load, to avoid choosing a motor that is either underpowered or unnecessarily oversized.

- Consider the level of speed control and precision you need, including whether your system requires encoders, position sensors or advanced motor controllers for smooth and consistent performance.

- Check the voltage and current specifications of your power supply and driver to ensure full electrical compatibility. A powerful motor will not perform well if your system cannot provide the required electrical input.

- Review the physical constraints of your design and confirm that the motor size, mounting options and shaft configuration fit comfortably within the available space.

- Take into account the environmental conditions, such as temperature, humidity, dust, vibration or chemical exposure, since these factors directly influence motor durability and reliability.

- Determine the duty cycle of your application so the motor can withstand the expected operating frequency and duration without overheating or wearing out prematurely.

- Ensure that the motor meets the necessary safety and compliance standards required for your industry, especially if you are working with medical devices, robotics or industrial automation systems.

When these factors are evaluated thoroughly, choosing the right motor becomes far easier and much more predictable. A well-matched high torque DC motor not only delivers power but also ensures long-term stability, efficiency and confidence in the performance of your entire system.

Conclusion

Choosing the right high torque DC motor is ultimately about precision: understanding your application, defining performance needs and selecting a motor that delivers power, efficiency and long-term reliability. With the right specifications in place, your system will operate smoother, respond faster and last longer. Invest the time to choose wisely and your motor becomes more than a component, it becomes a driver of performance and innovation for your entire application.