Precision and efficiency are at the heart of modern motion control systems. Direct drive linear motors are designed to meet these demands by eliminating mechanical transmission elements like gears or ball screws. The result is smooth, accurate, and highly reliable linear motion that is transforming industries from manufacturing to medical technology. This article will break down what a direct drive linear motor is, highlight its main advantages, and explore where it delivers the most impact.

What Is a Direct Drive Linear Motor?

A direct drive linear motor is a type of electric motor that produces motion in a straight line without the need for intermediate mechanical components such as gears, belts, or ball screws. Instead of converting rotary motion into linear motion, it generates force and movement directly, making it one of the most efficient and precise motion technologies available today.

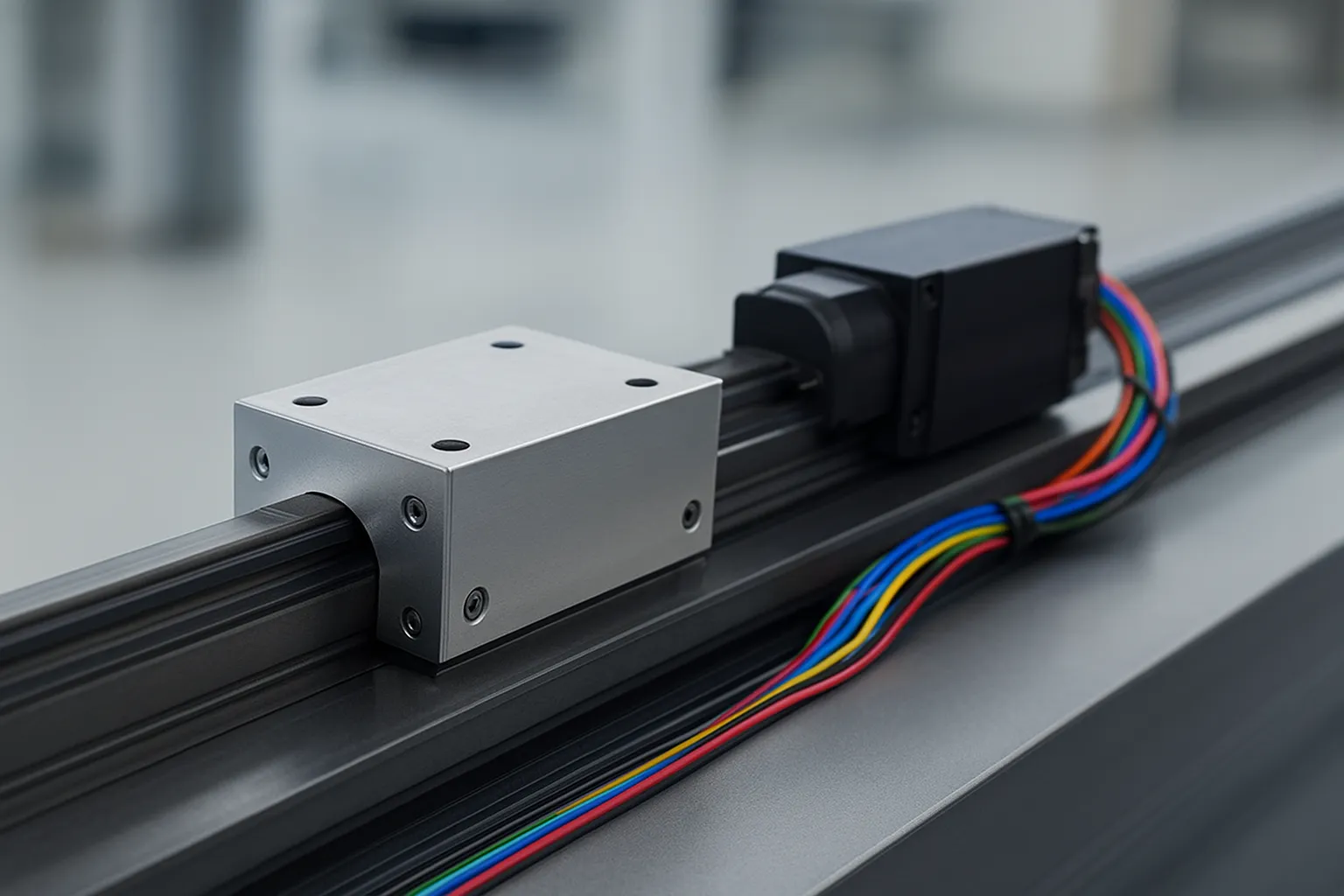

At its core, a direct drive linear motor consists of two main parts:

- The primary (forcer or stator): contains the coils that generate electromagnetic fields when powered.

- The secondary (track or magnet rail): made up of permanent magnets that interact with the coils to create motion.

When current flows through the coils, it produces a magnetic field that pushes or pulls against the magnets, resulting in smooth and direct linear movement. Because the system does not rely on mechanical transmission, it eliminates problems like backlash, wear, and vibration often found in conventional systems.

Direct drive linear motors come in different designs, with the two most common being:

- Ironcore Linear Motors: known for delivering very high force, suitable for heavy-duty applications.

- Ironless Linear Motors: provide smoother motion with no cogging, ideal for high-precision applications such as semiconductor manufacturing or medical devices.

In essence, a direct drive linear motor is not just a motor, it’s a solution that redefines how linear motion can be achieved, combining simplicity in design with advanced performance.

Key Advantages of Direct Drive Linear Motors

Direct drive linear motors have become increasingly popular because they solve many of the challenges associated with traditional motion systems. By eliminating mechanical transmission parts, they provide a set of advantages that make them highly suitable for demanding applications in automation, robotics, and precision engineering.

1. High Precision and Accuracy

One of the most significant benefits is their ability to deliver exceptionally precise motion. With no gears or ball screws to introduce errors, direct drive linear motors can achieve micron or even sub-micron positioning accuracy. This makes them ideal for industries like semiconductor manufacturing, where even the smallest deviation can affect quality.

2. Fast Response and High Speeds

Direct drive technology provides an immediate response to control signals, allowing the motor to accelerate and decelerate rapidly. This translates into shorter cycle times, higher throughput, and more efficient production processes without compromising accuracy.

3. Smooth and Quiet Operation

Because these motors move directly along a magnetic track, they operate with minimal vibration and noise. The lack of mechanical parts also means no backlash, no friction, and a much smoother motion profile, critical for applications that require stability, such as medical imaging systems.

4. Reduced Maintenance Requirements

Traditional motion systems rely on components like belts, gears, or screws that wear out over time and require regular maintenance. Direct drive linear motors remove these parts entirely, leading to lower maintenance costs and reduced downtime. Over the long term, this also increases the lifespan of the equipment.

5. Compact and Flexible Design

With fewer components, direct drive linear motors can be integrated into compact systems without sacrificing performance. This flexibility in design is especially valuable in space-constrained environments, such as high-precision lab equipment or compact automation cells.

6. Energy Efficiency

By eliminating energy losses associated with mechanical transmission, these motors provide more efficient power conversion. This not only reduces operating costs but also supports sustainable manufacturing practices.

In summary, the advantages of direct drive linear motors go beyond speed and accuracy. They bring efficiency, reliability, and long-term cost savings, making them an essential choice for industries that require high performance and minimal downtime. These benefits explain why more and more companies are shifting away from conventional systems toward direct drive technology.

Common Applications of Direct Drive Linear Motors

Direct drive linear motors are a key driver of innovation in industries that demand high precision, speed, and reliability. Unlike conventional systems, they eliminate mechanical transmission elements, reducing wear and maintenance while providing smoother motion.

This makes them versatile solutions across multiple sectors. Let’s explore their most impactful applications in detail.

1. Semiconductor and Electronics Manufacturing

The semiconductor industry is one of the most demanding in terms of precision. In chip fabrication, even a deviation as small as a micron can lead to defects and costly losses. Direct drive linear motors are widely adopted in this sector because they provide ultra-high precision positioning, stable performance, and high-speed operation.

They are used in wafer steppers, wafer inspection machines, and PCB assembly lines, where parts must be aligned with extreme accuracy. Unlike ball-screw or belt-driven systems, direct drive motors eliminate backlash and vibrations, ensuring smooth motion control. This precision translates into higher yield rates, less product waste, and lower overall production costs.

Additionally, the longevity and minimal maintenance of these motors are crucial in high-volume factories that run 24/7. By reducing downtime, they help manufacturers maintain continuous output and meet the growing demand for faster, smaller, and more powerful electronic devices.

2. Machine Tools and CNC Systems

In industries like automotive, aerospace, and precision engineering, CNC systems are indispensable. Direct drive linear motors bring significant improvements to machine tool performance by providing faster acceleration, higher speeds, and excellent repeatability.

For example, when cutting complex geometries or machining high-tolerance components, these motors ensure that the tool path remains consistent without deviations caused by mechanical friction. The result is better surface finish, reduced tool wear, and shorter production cycles.

In high-end CNC milling or grinding machines, direct drive technology allows manufacturers to achieve micron-level precision while working with tough materials such as titanium or composite alloys. This not only improves part quality but also increases competitiveness, as companies can deliver more accurate products in less time.

3. Robotics and Industrial Automation

As industries embrace Industry 4.0 and smart manufacturing, robotics has become central to modern automation. Direct drive linear motors empower robots with smooth, fast, and precise linear motion, which is essential for applications such as pick-and-place, high-speed packaging, material handling, and automated inspection.

Their high acceleration capability ensures robots can respond quickly to dynamic production demands. At the same time, their low-maintenance design reduces downtime, an essential factor in just-in-time manufacturing environments.

Beyond speed and precision, direct drive motors also contribute to energy efficiency, as they eliminate energy losses caused by friction in mechanical transmissions. This makes them attractive for industries looking to optimize operational costs while meeting sustainability goals.

4. Medical Devices and Imaging Systems

Healthcare technology requires motion solutions that are not only precise but also quiet, smooth, and vibration-free. Direct drive linear motors are particularly suited for this sector because they can deliver highly stable movement without introducing noise or mechanical disturbances.

In diagnostic imaging systems such as MRI, CT, and ultrasound machines, these motors ensure that scanning equipment moves smoothly, which leads to clearer and more accurate images. This precision is vital for doctors to make reliable diagnoses.

In surgical robotics, where movements must be both extremely precise and safe, direct drive motors provide the level of control needed for delicate procedures. They are also applied in laboratory automation such as automated sample handling and pharmaceutical production, where consistent accuracy and reliability are paramount.

Ultimately, these motors help improve patient outcomes by enabling more accurate diagnosis, safer surgeries, and faster medical research.

5. Aerospace and Defense Applications

Aerospace and defense are sectors where failure is not an option. Direct drive linear motors are extensively used in applications such as radar systems, satellite positioning, flight simulators, and aircraft testing. Their ability to deliver rapid acceleration, high precision, and long-lasting reliability makes them ideal for mission-critical systems.

For instance, in radar and surveillance systems, accurate positioning ensures that antennas can track objects with maximum efficiency. In flight simulators, direct drive motors replicate real-world conditions more effectively by providing smooth and responsive movement, improving pilot training quality.

Additionally, because these motors have fewer mechanical components, they can withstand harsh environments with less risk of breakdowns. This durability is a crucial advantage in defense applications where equipment must perform reliably under extreme conditions.

From the delicate world of semiconductor fabrication to the high-stakes demands of aerospace and defense, direct drive linear motors are proving themselves as versatile and indispensable technologies. Their ability to combine unmatched precision, high speed, and long-term reliability allows industries to break performance barriers that traditional motion systems cannot overcome.

Considerations Before Choosing Direct Drive Linear Motors

Before integrating direct drive linear motors into your system, it’s essential to evaluate several factors that influence performance, cost-effectiveness, and long-term reliability. Here are some key points to keep in mind:

- Required precision level: If your process demands micron-level accuracy, direct drive motors are the right choice. For less critical applications, however, traditional systems might deliver sufficient results at a lower cost.

- Load and force requirements: Not every system needs maximum thrust or force capacity. Clearly define the load your motor must handle to avoid oversizing, which can lead to unnecessary investment.

- Investment vs. long-term savings: While the initial cost of direct drive motors is typically higher, they reduce maintenance needs, downtime, and energy consumption. Evaluate the total cost of ownership (TCO) rather than focusing only on the upfront price.

- Complexity of installation: Because they eliminate mechanical transmission, direct drive linear motors require precise alignment and careful integration with motion controllers. Ensure you have the right technical expertise or a reliable partner for implementation.

- Operating environment: Temperature, humidity, dust, or high-vibration conditions may affect performance. Assess whether your working environment supports stable and long-term motor operation.

- Future scalability: If your production line may expand or evolve, consider motors that are easy to integrate with new systems or upgraded controllers, ensuring flexibility for the future.

In summary, choosing the right direct drive linear motor goes beyond technical specifications. It’s about striking a balance between performance needs, budget considerations, and long-term business strategy. When chosen wisely, these motors can become a cornerstone of efficiency and innovation, helping your business maintain a sustainable competitive edge.

Conclusion

Direct drive linear motors are more than just an alternative to conventional motion systems, they represent a leap forward in speed, precision, and efficiency. By delivering force directly without mechanical transmission, they eliminate common issues like backlash and wear, enabling industries to achieve levels of accuracy and productivity that were once difficult to imagine. From semiconductor fabrication and medical imaging to robotics and aerospace, their versatility is reshaping how technology moves.

For businesses considering this technology, it’s important to weigh the balance between initial investment, long-term savings, and application requirements. When applied strategically, direct drive linear motors can become the foundation for smarter, faster, and more reliable systems that drive innovation and competitiveness.

At ITG Linear Motors, we specialize in high-performance direct drive solutions designed to meet the diverse needs of modern industries. Whether your goal is extreme precision, smooth motion, or maximum productivity, our product line offers the technology and reliability to help you move ahead with confidence.