As industries move toward smarter automation and high-performance manufacturing, the demand for smooth, precise, and efficient linear motion continues to grow. This is where linear drive motors stand out. Unlike traditional rotary motors that require gears or screw mechanisms to create movement, linear drive motors produce direct linear force, delivering superior speed, accuracy, and reliability. From robotics and semiconductor production to medical imaging and advanced transportation, these motors are transforming the way modern systems achieve motion control.

What Is a Linear Drive Motor?

A linear drive motor is an advanced type of electric motor designed to generate motion in a straight line rather than rotational movement. Unlike conventional rotary motors that rely on additional mechanical components such as gears, screws, or belts to convert rotation into linear motion, linear drive motors create direct linear force. This unique ability eliminates the need for intermediary mechanisms, reducing energy loss, mechanical wear, and system complexity.

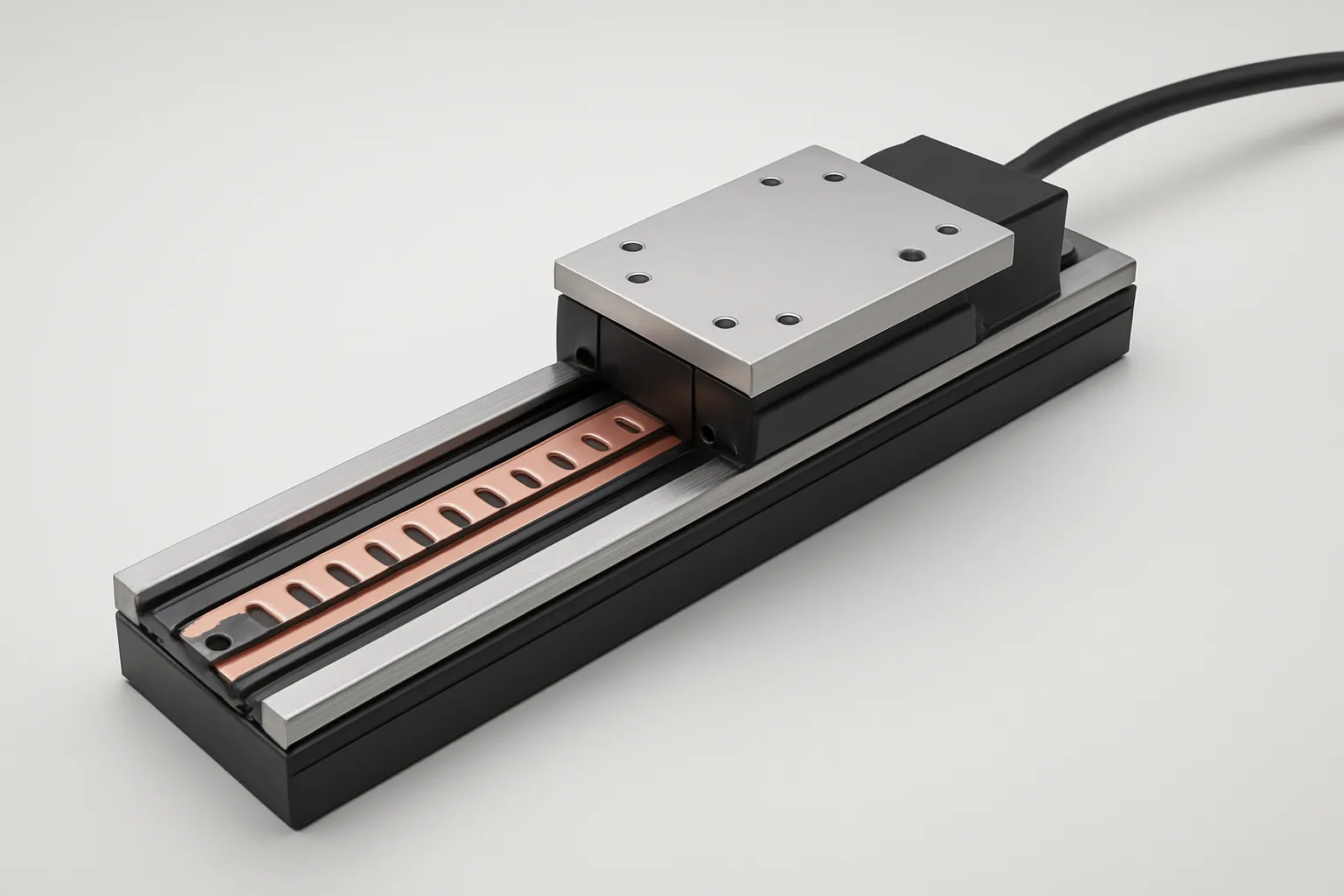

At its core, a linear drive motor consists of two main parts: a stator and a forcer (or slider). The stator contains coils and magnets that produce a controlled electromagnetic field, while the forcer moves along the stator track, generating precise linear motion. Because of this direct drive design, linear motors can achieve extremely smooth, accurate, and fast movements, making them ideal for applications where precision and reliability are critical.

What sets linear drive motors apart is their ability to combine high speed, high acceleration, and high positional accuracy all in one system. They are widely used in robotics, semiconductor manufacturing, medical devices, and CNC machinery, where traditional rotary motors with mechanical conversions would not be able to deliver the same level of efficiency and performance.

In short, a linear drive motor is not just a motor that moves in a straight line, it is a breakthrough in motion technology that redefines how industries design systems requiring direct, precise, and efficient linear motion.

How Do Linear Drive Motors Work?

Linear drive motors operate on the same fundamental principles as conventional electric motors but are engineered to deliver force in a straight line instead of rotational motion. At the heart of their operation is electromagnetic induction, the interaction between a magnetic field and electric current that produces motion.

A typical linear motor consists of two main components:

- The Stator (or Track): Usually embedded with permanent magnets arranged along a straight path.

- The Forcer (or Slider): Contains coils of wire that generate an electromagnetic field when powered.

When electric current passes through the coils of the forcer, it creates a magnetic field that interacts with the permanent magnets in the stator. This interaction generates a direct linear force, causing the forcer to move smoothly along the track. By precisely controlling the current and voltage, the system can regulate speed, position, and acceleration with exceptional accuracy.

Unlike rotary motors, which must convert rotational energy into linear motion using screws, belts, or gears, linear drive motors skip these intermediary mechanisms. This direct drive approach offers several benefits:

- Higher efficiency due to minimal energy loss.

- Greater precision because there are no mechanical components that introduce backlash or wear.

- Faster response times thanks to reduced inertia and friction.

To visualize this, imagine “unrolling” the stator of a rotary motor into a straight line. Instead of rotating around a shaft, the motor now pushes the slider forward in a perfectly straight path, this is the essence of how linear drive motors function.

With their ability to produce high speed, high acceleration, and highly accurate motion, linear drive motors have become essential in robotics, semiconductor production, CNC machinery, and medical imaging devices, where flawless precision and efficiency are critical.

Key Features of Linear Drive Motors

Linear drive motors have redefined motion control technology by introducing a new level of performance, precision, and reliability. Instead of relying on gears, screws, or belts to convert rotary motion into linear force, these motors directly generate motion along a straight path.

This breakthrough design provides a number of distinctive features that make them superior to conventional systems. Below are the most important features, explained in detail.

1. Direct Linear Motion

The most defining feature of a linear drive motor is its ability to create linear motion directly, without the need for intermediary mechanical systems. Traditional rotary motors must rely on gearboxes, ball screws, or belt-and-pulley mechanisms to translate rotary movement into linear displacement. While these methods can be effective, they introduce friction, energy loss, mechanical backlash, and long-term wear.

In contrast, linear motors eliminate these inefficiencies. By using electromagnetic forces to produce motion along a track, they allow machines to move precisely in a straight line without intermediate conversion. This not only improves energy efficiency but also enhances performance in applications that demand high accuracy and minimal vibration, such as semiconductor lithography or robotic arms.

2. High Precision and Accuracy

Precision is one of the greatest strengths of linear drive motors. Because there are no gears or mechanical components that can introduce slack or play, they achieve micron-level or even sub-micron-level accuracy in positioning. For industries such as CNC machining, semiconductor production, or laser engraving, this kind of accuracy is not optional, it is essential.

For example, in semiconductor wafer fabrication, even a tiny misalignment of a few microns can cause an entire batch of chips to fail. Linear motors solve this challenge by offering repeatable, precise motion every single time. Their capability to perform smooth, incremental steps also makes them ideal for medical imaging systems, where stable motion ensures clear, distortion-free images.

3. Superior Speed and Acceleration

Linear drive motors are also known for their dynamic performance. Unlike rotary motors with gear-driven systems that suffer from inertia and mechanical delays, linear motors have fewer moving parts and thus respond much faster to control signals. They can achieve exceptionally high acceleration rates, often several times higher than conventional systems, while still maintaining full control.

This makes them particularly valuable in high-speed manufacturing environments, such as automated packaging lines, pick-and-place robots, and laser cutting systems. For instance, a pick-and-place robot using a linear motor can rapidly accelerate, stop, and reverse direction without losing precision, dramatically boosting production throughput.

4. Smooth and Consistent Motion

Smooth motion is another hallmark of linear motors. Because they operate without gears or screws, there are no mechanical vibrations or inconsistencies caused by gear meshing or wear. Instead, linear motors deliver seamless, vibration-free movement across the entire range of motion.

This feature is crucial in applications where stability is paramount. In medical imaging systems such as MRI scanners or CT machines, even small vibrations can distort results and compromise diagnostic accuracy. Similarly, in laser-based manufacturing, consistent motion ensures that cuts or engravings are flawless, without jagged edges or imperfections.

5. Low Maintenance and Long Lifespan

Linear motors significantly reduce maintenance requirements compared to traditional motion systems. Mechanical drive systems rely on parts that wear out over time, such as ball screws, belts, or gearboxes, which require lubrication, replacement, and frequent servicing.

Because linear drive motors operate on a direct electromagnetic principle, there is little to no contact-based wear between moving parts. This drastically extends the lifespan of the system and reduces unplanned downtime. For companies operating in high-volume manufacturing, fewer maintenance interruptions translate into lower operational costs and improved productivity.

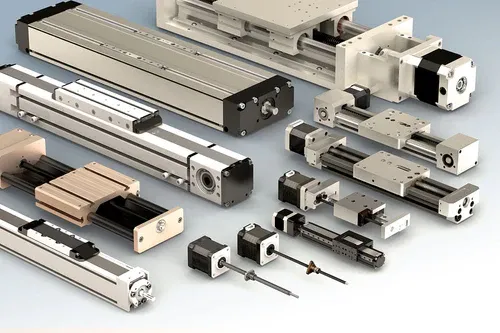

6. Compact and Flexible Design

Another key feature of linear drive motors is their ability to deliver exceptional power and performance within a compact footprint. Their slim, modular designs allow engineers to integrate them into equipment where space is limited, without sacrificing performance.

Moreover, linear motors can be customized to specific lengths or configurations, making them adaptable to a wide variety of industrial systems. This flexibility makes them suitable for both large-scale production lines and compact, high-precision devices like laboratory automation systems.

Taken together, these features explain why linear drive motors are becoming a preferred choice in industries that demand both speed and precision. Their direct-drive design eliminates inefficiencies, their precision ensures reliability, and their durability guarantees long-term performance. By combining all these qualities, linear drive motors do not just replace traditional systems, they enable entirely new possibilities in robotics, manufacturing, and beyond.

Advantages of Using Linear Drive Motors

The advantages of linear drive motors go beyond simple improvements in speed or accuracy. They represent a fundamental shift in how industries approach motion control, offering benefits that directly impact efficiency, reliability, and long-term performance. Some of the most notable advantages include:

- Higher efficiency and energy savings – Because linear drive motors generate motion directly, they eliminate the mechanical components that typically waste energy through friction and heat. This streamlined process not only ensures maximum energy transfer but also reduces power consumption, helping businesses cut operating costs while achieving superior performance.

- Greater speed and acceleration – With fewer moving parts and no intermediary mechanisms, linear motors can accelerate rapidly and reach high speeds without sacrificing control. This makes them ideal for production lines, pick-and-place systems, or precision cutting machines where every fraction of a second counts and faster cycles translate into higher throughput.

- Unmatched accuracy and repeatability – In industries like electronics, aerospace, and medical technology, accuracy is critical. Linear motors excel in delivering motion at micron-level precision with consistent repeatability. This ensures that processes like semiconductor lithography, surgical robotics, or laser machining can maintain exact specifications, batch after batch, without deviation.

- Reduced maintenance and downtime – By removing the reliance on gears, belts, and screws, linear motors minimize wear and tear, drastically reducing the need for servicing. For manufacturers, this means fewer unexpected breakdowns, lower maintenance budgets, and longer continuous operation, which is especially valuable in 24/7 production environments.

- Improved product quality – The smooth, vibration-free operation of linear motors ensures that delicate processes can be performed without distortion. Whether it’s producing flawless surface finishes in CNC machining or generating crystal-clear medical images, the stable motion contributes directly to better end results and higher product quality.

- Flexibility in design and scalability – Linear drive motors can be customized to different lengths, sizes, and power levels, making them highly adaptable to a wide range of industrial needs. From compact laboratory automation systems to large-scale production machinery, their modular design supports both versatility and innovation in engineering.

Altogether, these advantages explain why linear drive motors are increasingly replacing traditional rotary systems in high-performance industries. By combining efficiency, speed, and precision with long-term durability, they provide businesses with a solution that is not only technically superior but also economically strategic. Choosing linear drive motors is more than just a technical upgrade, it is an investment in future-ready innovation and sustainable growth.

Key Applications of Linear Drive Motors

Linear drive motors are not just theoretical advancements, they are practical solutions already driving innovation across multiple industries. Thanks to their precision, speed, and efficiency, these motors have found applications in a wide variety of fields where traditional rotary systems fall short. Below are some of the most prominent areas where linear drive motors are making a significant impact:

1. Industrial Automation and Robotics

Automation relies on fast, precise, and reliable motion control, and linear drive motors provide exactly that. In robotic arms, assembly lines, and automated packaging systems, these motors enable smooth and accurate movement without the delays caused by mechanical gears or belts. For pick-and-place operations, linear motors ensure components are moved swiftly and positioned with exact precision, which boosts productivity while maintaining product quality.

2. Semiconductor and Electronics Manufacturing

Few industries demand as much precision as semiconductor production, where microscopic tolerances can make or break a product. Linear drive motors excel in lithography, wafer inspection, and chip packaging because they deliver sub-micron accuracy with repeatable consistency. In electronics assembly, such as printed circuit board (PCB) manufacturing, they ensure components are soldered or placed flawlessly.

3. Medical and Healthcare Equipment

From diagnostic imaging to surgical robotics, linear drive motors are revolutionizing healthcare technology. In MRI and CT scanners, their ability to provide smooth, vibration-free motion enhances image clarity, which is critical for accurate diagnoses. In robotic-assisted surgeries, linear motors allow surgeons to perform delicate procedures with ultra-precise movements, improving patient outcomes while reducing recovery times.

4. Transportation and Aerospace

Transportation systems, including maglev trains, heavily rely on linear drive motors for high-speed, contactless propulsion. This not only enables rapid transit but also reduces friction, noise, and wear, extending system longevity. In aerospace, linear motors are used in flight simulators, satellite positioning, and even launch systems due to their ability to deliver powerful, precise, and reliable motion. These applications highlight the versatility of linear motors in environments where both performance and safety are non-negotiable.

5. CNC Machining and Material Processing

Manufacturers in industries like automotive, metalworking, and woodworking are increasingly adopting linear drive motors for CNC (Computer Numerical Control) machining. Their smooth and accurate motion ensures high-quality cuts, fine surface finishes, and faster cycle times. In laser cutting, engraving, and 3D printing, linear motors allow for intricate detailing without deviation, improving both efficiency and product quality.

6. Research, Testing, and Laboratory Automation

In scientific research and laboratory environments, precision and repeatability are critical. Linear drive motors are used in testing equipment, optical instruments, and automated lab systems to move samples or instruments with pinpoint accuracy. This ensures that experiments can be replicated under identical conditions, leading to more reliable results.

The applications of linear drive motors extend far beyond these examples, but the common thread is clear: industries that require high precision, reliability, and efficiency benefit the most from adopting this technology. From powering the fastest trains to enabling life-saving surgeries, linear drive motors are at the heart of innovation in modern engineering.

Conclusion

Linear drive motors are more than just an alternative to traditional motion systems, they represent a fundamental leap forward in precision engineering. By eliminating mechanical complexity and delivering unmatched speed, accuracy, and reliability, they empower industries ranging from automation and semiconductor manufacturing to aerospace and healthcare.

Their adaptability makes them not only a solution for today’s challenges but also a cornerstone for tomorrow’s innovations. As the demand for smarter, faster, and more efficient technology continues to grow, linear drive motors will remain at the forefront of shaping the future of motion control.