Imagine a world where machines move with human-like precision, arms that glide smoothly, platforms that shift effortlessly, and systems that react in milliseconds. At the heart of these movements lies an unsung hero: the Linear Actuator Motor. But what is it really, and how does it make the impossible look so simple? Let’s peel back the layers of this fascinating technology.

What is a Linear Actuator Motor?

A Linear Actuator Motor is a specialized device designed to convert rotary motion into linear motion, enabling controlled back-and-forth or up-and-down movements. Unlike traditional rotary motors that spin continuously, a linear actuator motor delivers precise straight-line motion, making it essential for applications that require accuracy, stability, and force.

At its core, the motor provides the initial rotational energy, which is then transformed into linear displacement through mechanisms such as lead screws, ball screws, or belt drives. This unique capability allows machines to push, pull, lift, or position objects with a high degree of precision.

Linear actuator motors are widely used across industries, from robotics and automation systems to medical equipment, aerospace engineering, and manufacturing lines. Whether it’s adjusting the position of a surgical table or guiding a robotic arm on an assembly line, these actuators serve as the hidden force that makes motion possible.

What sets them apart is their ability to deliver high thrust, smooth movement, and consistent accuracy, even under heavy loads, qualities that make them indispensable in modern engineering and technology.

3 Types of Linear Actuator Motors

Linear actuator motors come in several types, each designed for specific applications and performance requirements. The three most common types are electric, hydraulic, and pneumatic actuators.

1. Electric Linear Actuator Motors

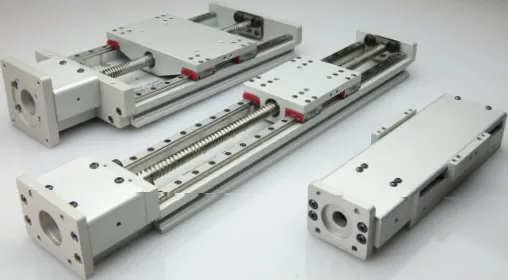

Electric linear actuators are powered by electric motors such as DC, AC, stepper, or servo motors to generate rotary motion, which is then converted into linear displacement using screw mechanisms like lead screws or ball screws.

- Advantages: High precision, easy integration with control systems, low maintenance, and clean operation (no fluids required).

- Applications: Robotics, industrial automation, adjustable hospital beds, CNC machinery, and aerospace systems.

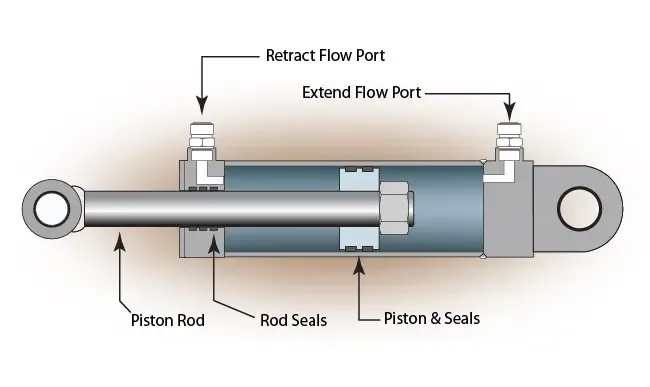

2. Hydraulic Linear Actuator Motors

Hydraulic actuators use pressurized fluid to create linear movement. They are known for delivering very high force and torque, making them ideal for heavy-duty operations.

- Advantages: Extremely powerful, suitable for large loads and harsh environments.

- Limitations: Requires pumps, valves, and fluid reservoirs; more maintenance; potential for fluid leaks.

- Applications: Construction equipment, heavy machinery, and aerospace actuation systems.

3. Pneumatic Linear Actuator Motors

Pneumatic actuators operate using compressed air to produce motion. They are lightweight, fast, and reliable for applications requiring repetitive motion.

- Advantages: Quick response time, cost-effective, and simple design.

- Limitations: Lower precision compared to electric actuators, requires an air compressor.

- Applications: Packaging machines, material handling systems, and automated production lines.

Choosing the right type depends on force requirements, speed, environment, and control precision. Electric actuators dominate applications needing accuracy and programmability, while hydraulic and pneumatic actuators excel in power and speed-critical systems.

Key Components of a Linear Actuator Motor

A linear actuator motor is more than just a motor, it’s a complete system of components working together to achieve smooth, controlled linear motion. Below are the essential parts that make this transformation possible:

1. Motor Unit

The heart of the actuator, the motor generates the initial rotary motion. Common types include DC motors for cost-effective solutions, servo motors for high precision, and stepper motors for accurate incremental movement. The choice of motor greatly affects speed, torque, and control capability.

2. Screw Mechanism (Lead Screw or Ball Screw)

This component converts the motor’s rotational energy into linear motion.

- Lead Screws: Cost-effective, smooth operation, best for moderate loads.

- Ball Screws: High efficiency, low friction, suitable for heavy loads and long service life.

3. Housing and Mounting Assembly

The housing provides structural support, protects internal components, and ensures alignment during movement. Mounting brackets and flanges secure the actuator to machinery, guaranteeing stability and accuracy.

4. Guide System

Guides maintain linear alignment and prevent unwanted rotation or bending during motion. They are critical for achieving smooth, precise travel, especially under load.

5. Sensors and Feedback Devices

For precision control, many actuators include limit switches, position sensors, or encoders. These components provide feedback to the control system, enabling accurate positioning and safety in automated applications.

6. Control System (Optional)

Advanced systems integrate a controller or driver to manage speed, direction, and positioning. This is essential for robotic systems or industrial automation requiring programmable motion.

In essence, each component plays a specific role in ensuring the actuator can handle force, maintain precision, and operate reliably in demanding conditions.

How Does a Linear Actuator Motor Work?

At its essence, a linear actuator motor performs one elegant task: turning rotational energy into linear movement. But the way it achieves this is a fascinating blend of mechanics, control, and precision engineering.

From Signal to Motion

The process begins with a command maybe from a human operator pressing a button, or an automated system running a program. This signal activates the motor, causing its shaft to rotate at a controlled speed. Different motor types handle this differently: a DC motor spins continuously, a stepper moves in small increments, and a servo motor adjusts its position with pinpoint accuracy.

The Conversion Trick: Rotation to Translation

Here’s where the transformation happens. The motor’s shaft connects to a screw mechanism, typically a lead screw or ball screw. Picture a spiral staircase: when you twist it, something moves upward or downward along its path.

In the same way, as the screw turns, a nut rides along its threads, pushing or pulling the connected load in a perfectly straight line. This is the heart of the actuator’s magic taking circles and making them lines.

Guidance and Precision Control

Simply moving isn’t enough; it needs to be stable and accurate. That’s why actuators include guide rails or internal bearings to prevent wobbling or twisting under load. For applications like robotics or medical devices, precision sensors and encoders provide constant feedback to the control system. This feedback ensures the actuator stops exactly where it should, down to fractions of a millimeter.

Reverse and Regulate

Need the motion to reverse? Just change the motor’s rotation direction. Want it faster or slower? Adjust the power input or use a control driver. Modern actuators can even handle complex motion profiles accelerating smoothly, stopping gently, or syncing with other actuators for coordinated movement.

Think about an adjustable hospital bed. When the patient presses a button, the controller signals the actuator. The motor spins, the screw converts that spin into a slow, controlled push, and the bed tilts upward. Sensors confirm the position and stop the motion exactly where needed. Smooth, quiet, and precise, this is everyday magic powered by linear actuator motors.

Applications of Linear Actuator Motors

Linear actuator motors are everywhere even if you rarely notice them. They play a crucial role in industries where precision, control, and reliability are non-negotiable. Let’s explore some of the most common (and fascinating) applications:

1. Robotics and Automation

Robots wouldn’t move with surgical precision without actuators. Linear actuators control robotic arms, grippers, and positioning systems, enabling tasks like assembly, packaging, and welding with millimeter accuracy. In automated warehouses, actuators help robotic systems pick and place items efficiently, keeping logistics running smoothly.

2. Medical and Healthcare Equipment

From hospital beds and patient lifts to surgical tables and imaging devices, linear actuators make healthcare safer and more comfortable. They allow quiet, smooth adjustments for patient positioning or fine-tuned control during surgery, where precision can save lives.

3. Industrial Machinery

Factories rely on actuators for everything from conveyor systems to CNC machines. These motors handle heavy loads, move components with exact force, and ensure production lines stay efficient and accurate.

4. Aerospace and Automotive

In aerospace, actuators manage flight control surfaces, cargo doors, and seat positioning. In automotive systems, they control adjustable seats, throttle systems, and electric tailgates, delivering convenience and safety in everyday driving.

5. Renewable Energy Systems

Even solar tracking systems depend on linear actuators. By adjusting panel angles throughout the day, actuators help maximize energy capture, boosting efficiency in solar farms.

Wherever there’s a need for controlled linear motion, from delicate surgical tools to massive industrial machines, linear actuator motors are the silent force making it happen.

Conclusion

Linear actuator motors may work behind the scenes, but their impact on modern technology is impossible to ignore. From robotics and healthcare to aerospace and renewable energy, these devices transform simple rotational power into the kind of controlled, precise movement that drives innovation.

As automation becomes more advanced and industries demand greater accuracy, linear actuators will remain at the heart of countless applications, quietly powering the future of motion.

So, the next time you see a robotic arm moving flawlessly or a hospital bed adjusting smoothly, you’ll know the hidden hero making it all possible. Want to dive deeper into actuator technology or choose the right model for your application? Start exploring now, the future of precision begins here.