When it comes to converting electrical energy into precise linear motion, two terms often create confusion: linear actuator motor and linear motor. At first glance, they might sound interchangeable but in reality, they serve very different purposes and operate on distinct principles. Whether you’re designing an automated system or selecting motion components for a new project, understanding the difference can save time, money, and performance issues down the line. So, what is a linear actuator motor and how is it different from a linear motor? Let’s dive in and break it down.

What is a Linear Actuator Motor?

A common question in the world of automation is: what is a linear actuator motor? Simply put, it’s a device designed to create straight-line motion by converting the rotary motion of an electric motor into linear displacement. Instead of spinning like a typical motor, a linear actuator motor pushes or pulls along a straight path making it perfect for applications that require controlled, precise movement.

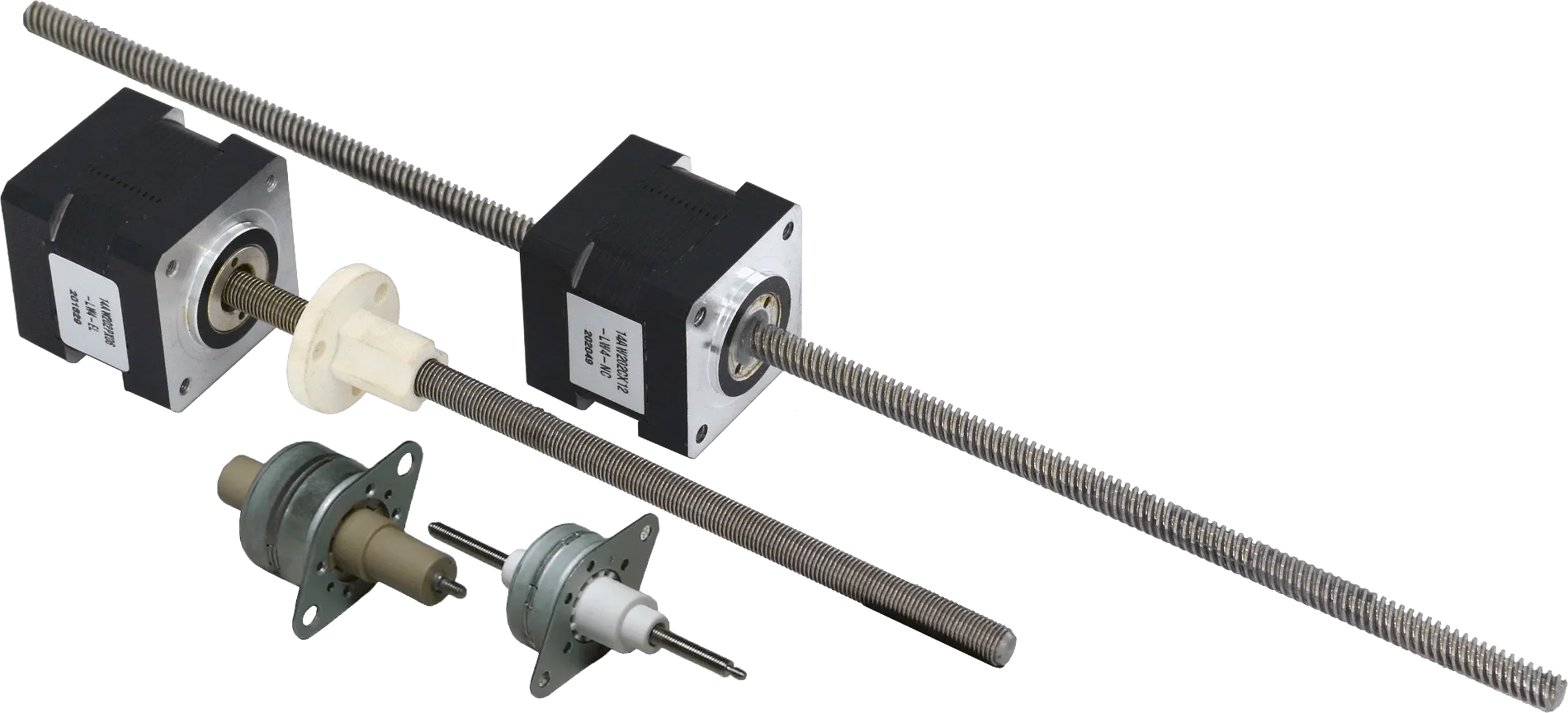

Most linear actuator motors rely on mechanical systems such as lead screws, ball screws, or belts to transform rotational energy into linear motion. These mechanisms allow the actuator to extend and retract with force, accuracy, and stability.

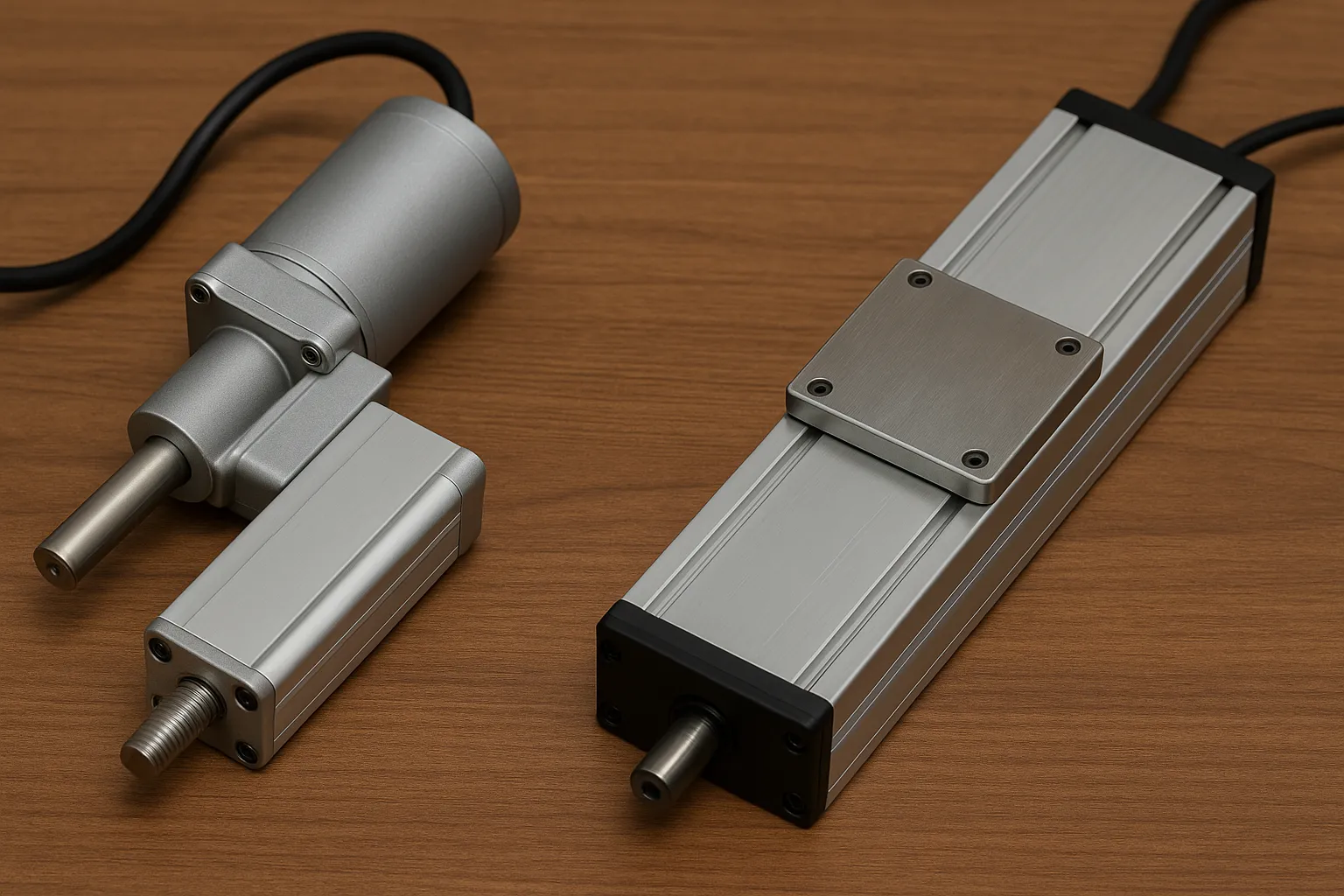

Depending on the design, a linear actuator motor can be powered by electricity, hydraulics, or pneumatics. However, electric linear actuators are the most widely used today due to their efficiency, compact form, and ease of integration with modern control systems.

Whether you’re lifting, tilting, sliding, or positioning an object, a linear actuator motor offers a reliable solution for achieving smooth, programmable linear motion.

Linear actuator motors come in many forms, but the most common types include:

- Electric linear actuators, which use AC or DC motors to drive mechanical components.

- Hydraulic linear actuators, which use pressurized fluid to generate motion.

- Pneumatic linear actuators, which rely on compressed air for movement.

Each type is suited for different applications, with varying degrees of precision, power, and complexity. However, in this article, our primary focus is on electric linear actuator motors, due to their versatility and prevalence in modern automated systems.

Applications of Linear Actuator Motors

Now that we understand what is a linear actuator motor, it’s clear why this technology is widely used across industries that require precise, programmable linear motion. From everyday consumer devices to complex industrial systems, the versatility of linear actuator motors makes them essential in countless applications.

1. Industrial Automation

In manufacturing environments, linear actuator motors are used for tasks such as pushing, pulling, lifting, positioning, and sorting. Their ability to operate with high reliability and repeatability makes them perfect for robotic arms, conveyor systems, and material handling equipment.

2. Medical and Healthcare Devices

Ever wondered what powers the smooth adjustment of hospital beds or dental chairs? That’s right linear actuator motors. These motors offer quiet, hygienic, and space-efficient motion control in medical equipment, where comfort and precision are crucial.

3. Home Automation and Smart Furniture

As smart homes become more common, linear actuator motors are increasingly used in adjustable beds, motorized standing desks, window openers, and hidden storage lifts. Their compact size and easy integration make them ideal for enhancing modern living spaces.

4. Solar and Renewable Energy Systems

Solar trackers rely on linear actuator motors to follow the sun’s movement across the sky. By adjusting the angle of solar panels throughout the day, they help maximize energy output. In this case, durability and weather resistance are just as important as smooth motion.

5. Automotive and Transportation

From power-adjustable car seats to tailgate openers and mirror adjusters, linear actuator motors are found in many modern vehicles. In heavy-duty and off-road vehicles, they support automated hatch lifts, hydraulic blade positioning, and more.

6. Aerospace and Defense

In high-stakes environments, reliability is everything. Linear actuator motors are used in aircraft wing adjustments, missile systems, and satellite equipment where precision and consistency under extreme conditions are non-negotiable.

In short, once you understand what is a linear actuator motor, you’ll begin to see just how integral this compact yet powerful device is in both everyday life and advanced engineering systems.

What is a Linear Motor?

A linear motor is a type of electric motor that generates motion in a straight line without the need for mechanical transmission systems like screws, belts, or gears. Instead of converting rotary motion into linear motion as a linear actuator motor does a linear motor delivers direct-drive linear force through electromagnetic fields.

Structurally, you can think of it as an unrolled rotary motor. The “stator” and “rotor” are laid out flat, creating a moving magnetic field that pushes the load along a linear path. This configuration eliminates mechanical contact and friction, enabling extremely fast, precise, and smooth motion with minimal wear and maintenance.

Linear motors are commonly used in high-performance environments where precision and speed are critical such as CNC machines, semiconductor equipment, packaging lines, and magnetic levitation systems. However, they are generally more expensive, require complex control systems, and are sensitive to environmental conditions like dust or vibration.

While both linear motors and linear actuator motors aim to achieve linear motion, they do so in fundamentally different ways each with unique trade-offs in cost, complexity, force output, and application fit.

Want to explore linear motors in more detail? Check out our full article on linear motor technology.

Linear Actuator Motor vs. Linear Motor: Key Differences

Although both technologies aim to achieve linear motion, the differences between a linear actuator motor and a linear motor are substantially affecting everything from design decisions to long-term system performance.

For engineers, integrators, and decision-makers, understanding these distinctions is just as important as knowing what is a linear actuator motor in the first place.

1. Principle of Operation

The most fundamental difference lies in how motion is generated:

- A linear actuator motor first uses a rotary electric motor to create rotational force, which is then converted into linear movement via mechanical components like lead screws, ball screws, or belt drives. In other words, the motion is indirect and relies on mechanical translation.

- A linear motor, in contrast, creates linear motion directly using electromagnetic force. It’s essentially an “unrolled” electric motor where the rotor and stator are arranged linearly. This direct-drive mechanism eliminates the need for intermediary mechanics.

2. Speed and Responsiveness

Linear motors offer exceptional speed and acceleration, often outperforming actuator systems by a wide margin. Because they don’t suffer from mechanical inertia or screw friction, linear motors are ideal for high-speed applications that require instantaneous response and microsecond-level precision.

On the other hand, a linear actuator motor typically moves more slowly and smoothly perfectly suited for tasks like lifting, pushing, or adjusting where controlled, steady force is more important than speed.

3. Force and Load Handling

If you’re wondering what is a linear actuator motor best used for, the answer is: pushing and pulling heavy loads with mechanical advantage. The use of gears or screw drives allows linear actuators to produce significant thrust with a compact footprint.

In contrast, linear motors may struggle with very high-force applications unless they are custom-engineered with large form factors and complex cooling systems.

4. Precision and Positioning

When it comes to high-precision motion control, linear motors dominate. Their direct electromagnetic actuation allows for sub-micron accuracy and seamless motion profiles ideal for semiconductor machines, optical inspection systems, and ultra-fine CNC tools.

When it comes to high-precision motion control, linear motors dominate

That said, modern linear actuator motors can also incorporate encoders and feedback loops to improve positioning accuracy, making them suitable for moderately precise applications at a lower cost.

5. Cost and Complexity

If you’re designing a system on a tight budget, a linear actuator motor is often the more practical choice. It’s less expensive, easier to install, and integrates well with traditional motion control setups. You can easily find off-the-shelf models to match a wide variety of stroke lengths and force requirements.

Linear motors, by contrast, are more costly not just in terms of hardware, but also due to the specialized drives, alignment requirements, and control algorithms they demand.

6. Maintenance and Longevity

Because linear motors have fewer mechanical components, they tend to require less maintenance over time. With no contact-based wear points like screws or belts, they offer longer service life in clean, controlled environments.

However, in industrial or outdoor conditions, the robust build and mechanical simplicity of linear actuator motors may prove more reliable. If you’re asking what is a linear actuator motor good for in the real world, it’s about durability, serviceability, and environmental tolerance.

How to Choose Between Them?

Choosing between a linear actuator motor and a linear motor depends less on which one is “better,” and more on what your application actually demands. Each has its own strengths, trade-offs, and ideal use cases.

If your system involves pushing or pulling with consistent force like adjusting a platform, lifting a load, or extending a part at moderate force, a linear actuator motor might be more than enough. Its simple structure, mechanical leverage, and cost-effectiveness make it a practical choice in many industrial, medical, or consumer products.

However, in scenarios where speed, responsiveness, and pinpoint accuracy are critical such as high-speed sorting, semiconductor processing, or advanced robotics a linear motor might offer the performance edge you need. Its direct-drive architecture can reduce mechanical wear and support faster cycles, though it often comes with increased complexity and cost.

It’s also worth considering environmental factors. If your setup is exposed to dust, moisture, or heavy-duty mechanical stress, a sealed actuator motor might hold up better. In cleanroom conditions, the frictionless design of a linear motor could extend system life and stability.

In short, there’s no one-size-fits-all answer. Rather than asking which technology is superior, start by defining your requirements: load, speed, precision, space constraints, and budget. From there, the right choice will likely reveal itself.

Conclusion

Understanding what is a linear actuator motor and how it differs from a linear motor, is key to making informed choices in motion control design. While both technologies produce linear motion, their mechanisms, strengths, and ideal applications vary significantly.

Linear actuator motors offer robust performance, simple integration, and high load capacity, making them well-suited for a wide range of industrial and consumer uses. Linear motors, on the other hand, provide unmatched speed and precision, ideal for high-tech, high-speed environments.

Ultimately, the best solution depends on your project’s specific requirements, there is no universal answer. By taking the time to evaluate factors such as load, accuracy, speed, cost, and environment, you’ll be better equipped to select the motion system that delivers lasting value and performance.