Linear motors are transforming motion control with high speed, precision, and direct-drive simplicity. Two key types ironless linear motors and iron core linear motors serve different industrial needs, from semiconductors to CNC systems.

This article compares their construction, features, and ideal applications to help you choose the right solution. Whether you’re upgrading motion systems or evaluating top linear motor manufacturers, this guide offers a clear starting point in the world of linear motor technology.

Introduction to Linear Motor Technologies

The rising demand for precision motion in automation

Today, the demand for linear motor technology is rapidly growing. Industries require high-precision, high-speed, and repeatable linear movement for applications such as packaging, laser cutting, semiconductor inspection, inkjet printing, and biomedical devices. Compared to traditional mechanical drive systems (like ball screws or rack-and-pinion), linear motors offer direct-drive motion with zero backlash, reduced mechanical wear, and significantly higher bandwidth and rigidity.

This evolution enables engineers to design more compact, low-maintenance, and responsive machines essential in both high-throughput manufacturing and precision-critical environments.

The ecosystem of leading linear motor manufacturers

Top-tier linear motor manufacturers such as ITG offer both iron core and ironless product lines. Their solutions are tailored for industries ranging from industrial automation to semiconductor and vacuum applications.

ITG specialize in ironless vacuum linear motors, while also offering low-cogging iron core motors for hybrid performance demands.

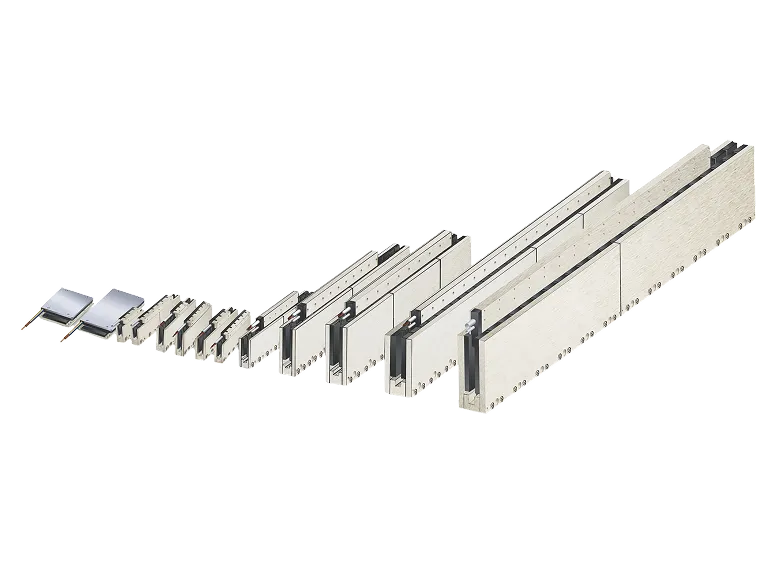

What is an Ironless Linear Motor?

Definition and Construction

An ironless linear motor, also known as a coreless linear motor, is a direct-drive actuator that delivers linear motion without the use of iron in the moving coil. Unlike iron core linear motors, which use laminated iron to amplify magnetic flux, the ironless design eliminates the iron altogether. Instead, its moving coil consists of copper windings embedded in a lightweight, non-magnetic carrier typically epoxy or aluminum.

At ITG, our ironless linear motor solutions are engineered with a U-shaped magnetic track configuration, where the coil moves between two magnet rows. This structure results in a completely cog-free, zero-attraction-force system ideal for high-precision applications. By removing the iron, we reduce weight and electromagnetic interference, making it an essential component of modern linear motor technology.

Key Features of Ironless Linear Motors

Zero Cogging

Without an iron core, these motors experience virtually no cogging torque, eliminating force ripple and enabling uniform velocity even at extremely low speeds. This makes them ideal for precision tasks such as wafer handling, metrology, or biomedical device positioning.

Smooth, Vibration‑free Motion

With no attraction forces between moving parts and fixed magnets and thanks to low moving mass ironless motors deliver exceptionally smooth, vibration-free, and responsive operation. Designers also benefit from extremely fast settling (sub‑millisecond time constants).

Ideal for Lightweight and Cleanroom Applications

The low mass and frictionless design mean faster acceleration and minimal wear, significantly prolonging bearing life. Ironless motors are vacuum-compatible and cleanroom-ready, making them ideal for semiconductor, biotech, and metrology environments where zero contamination and sub-micron accuracy are critical.

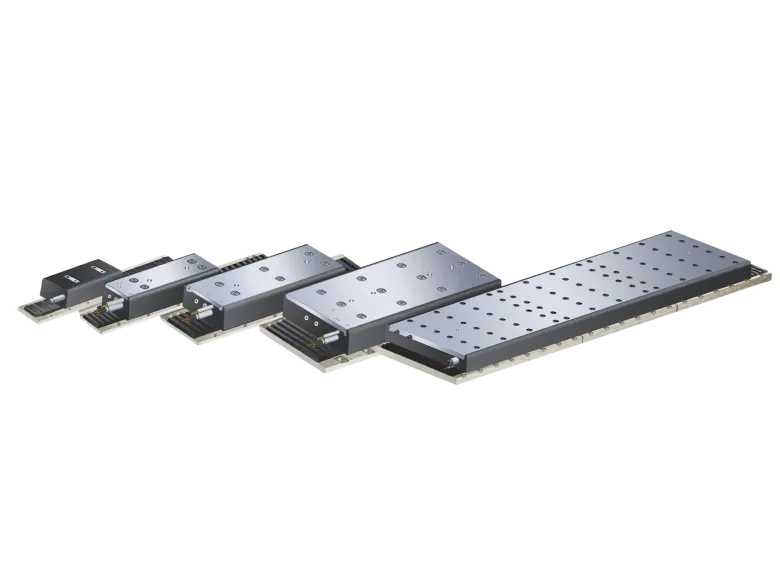

What is an Ironcore Linear Motor?

Definition and Working Principle

An iron core linear motor is a type of linear motor technology where the moving part (called the forcer) contains copper windings wound around laminated iron cores. The stationary part consists of permanent magnets arranged in a linear fashion along a magnet track. As current passes through the windings, an electromagnetic field is generated, interacting with the magnetic field from the track to produce direct linear motion.

Unlike ironless linear motors, ironcore designs incorporate ferromagnetic materials in the coil, significantly increasing the magnetic flux density. This allows for higher continuous and peak forces making ironcore motors ideal for heavy-duty applications in industrial automation, CNC machinery, and packaging lines.

At ITG, our iron core linear motor systems are optimized for demanding environments where high force output, durability, and thermal management are critical.

Key Features of Ironcore Linear Motors

High Force Output

One of the most defining benefits of iron core linear motors is their ability to deliver extremely high thrust density. The laminated iron core concentrates magnetic flux, enabling more efficient conversion of electrical energy into linear force. This makes them ideal for applications requiring large payloads, such as metal cutting or high-speed production equipment.

Thermal Efficiency

Thanks to their robust design, ironcore motors offer superior thermal performance. The iron core acts as a heat sink, allowing better dissipation of generated heat. Combined with ITG’s advanced cooling mechanisms, this ensures stable operation in continuous-duty applications without the need for oversized components.

Cost-Effective for Industrial Environments

For industries looking for powerful and cost-efficient linear motion solutions, ironcore motors provide excellent value. Their compact size, high force-to-cost ratio, and simple mechanical integration make them a preferred choice among linear motor manufacturers for mainstream industrial use.

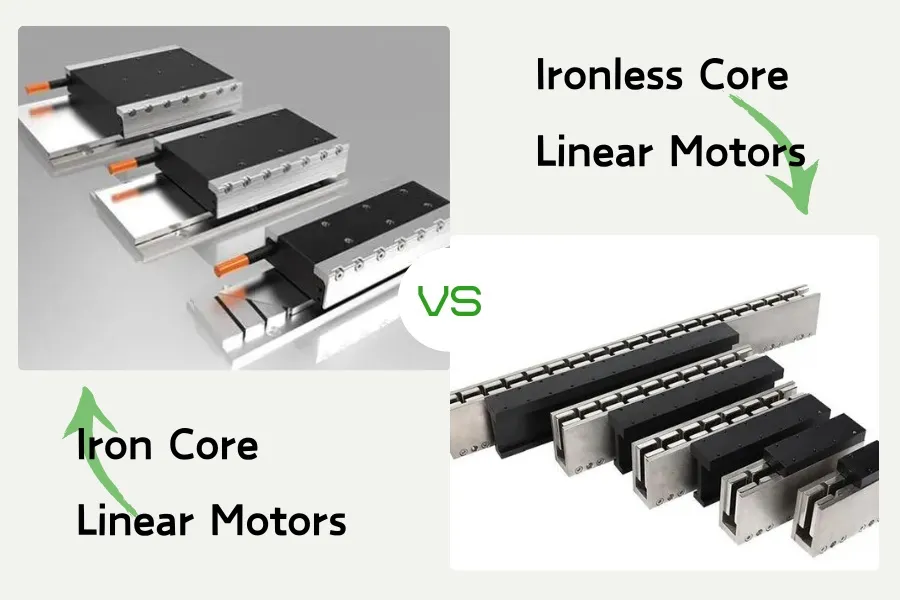

Ironcore vs Ironless Linear Motors – A Detailed Comparison

As linear motor technology continues to evolve, the choice between an iron core linear motor and an ironless linear motor becomes critical for engineers, system designers, and manufacturers. Both types of motors offer unique advantages depending on the performance, environment, and budgetary requirements. This section explores key comparison points to help you make informed decisions.

Performance Metrics

When it comes to raw performance, each motor type delivers different strengths:

- Force Output: Iron core linear motors generate significantly higher continuous and peak forces thanks to their ferromagnetic cores. This makes them suitable for heavy-load applications such as CNC machines, stamping lines, and high-speed packaging.

- Cogging & Smoothness: Ironless linear motors are completely cog-free, delivering ultra-smooth and vibration-free motion. This advantage is critical for applications in semiconductor manufacturing, metrology, and cleanroom automation where nanometer-level precision is required.

- Acceleration & Inertia: With a lightweight moving coil and no iron, ironless motors offer better dynamic response and lower inertia, making them suitable for fast, precise movements with minimal overshoot.

- Thermal Performance: Ironcore motors dissipate heat efficiently through their iron cores, allowing for continuous high-duty operation. Ironless motors, though less heat-tolerant, can still perform exceptionally well in short-cycle or vacuum environments with proper thermal management.

Summary:

- Choose iron core linear motors for high force and continuous-duty industrial applications.

- Choose ironless linear motors for smooth, high-precision motion and low-vibration environments.

Cost vs. Precision Consideration

Budget is a key factor in any motion system investment. While ironcore motors are generally more cost-effective in terms of price-to-force ratio, ironless motors provide greater precision at a higher cost due to their complex manufacturing and specialized materials.

Ironcore Linear Motors:

- Lower manufacturing cost

- Easier to integrate in standard automation systems

- Best for applications where precision can be balanced with performance

Ironless Linear Motors:

- Higher upfront cost, but lower maintenance in precision environments

- Ideal for cleanroom, ultra-precise, or vacuum applications

- Require more careful thermal and mounting design

Linear Motor applications – Which type fits your needs?

Choosing the right motor is critical to maximizing the performance, efficiency, and lifespan of your motion system. Whether you’re working in industrial automation or ultra-clean semiconductor environments, understanding the strengths of each linear motor technology helps you select the right fit. Below is a breakdown of when to choose an iron core linear motor or an ironless linear motor, depending on your application demands.

When to Choose Ironcore Linear Motors

If your application involves high thrust, robust industrial environments, or cost-sensitive scaling, then iron core linear motors are your go-to solution.

Ideal applications include:

- CNC machining centers requiring constant, high-force linear movement

- Robotic actuators in heavy-duty production lines

- Packaging and assembly systems where throughput speed and payload are key

- Material handling and stamping systems in factory automation

Thanks to their high magnetic force density and thermal stability, ironcore motors offer exceptional performance in demanding tasks. Their compact size, combined with a high force-to-cost ratio, makes them a popular choice among linear motor manufacturers for scalable industrial deployment.

When to Choose Ironless Linear Motors

For industries where smooth, precise, and cog-free motion is essential, ironless linear motors are the preferred solution. With no magnetic attraction between the coil and magnets, they offer unmatched motion quality with zero cogging and minimal vibration.

Ideal applications include:

- Semiconductor fabrication systems, wafer inspection, and lithography

- Biotech instrumentation requiring ultra-smooth operation

- Precision metrology and optical systems

- Cleanroom and vacuum environments, where particle generation must be minimized

Due to their lightweight coil design and precision focus, ironless motors are optimal for applications that cannot tolerate magnetic cogging or mechanical disturbances.

Explore ITG’s Linear Motor Solutions

At ITG, we specialize in both iron core and ironless linear motor systems, tailored to meet the dynamic needs of modern industries. As a trusted linear motor manufacturer, our products are engineered with precision, efficiency, and performance in mind.

Explore our robust solutions built for high-force industrial environments: Ironcore Linear Motors.

Discover motion systems designed for accuracy, quiet operation, and cleanroom compatibility: Ironless Linear Motors.

Conclusion

In summary, both iron core linear motors and ironless linear motors serve vital roles in modern linear motor technology. While ironcore motors excel in high-force, cost-sensitive industrial tasks, ironless motors are unmatched in precision-critical, cog-free applications like semiconductor and biotech. Choosing the right solution depends on your performance priorities and as one of the trusted linear motor manufacturers, ITG is here to help. Explore our product range or contact our engineers today for expert guidance.