Imagine a world where machines glide with absolute precision, where every movement is flawless and every process runs without disruption. This is the reality made possible by vacuum linear motors, the silent powerhouses behind today’s most advanced technologies. Yet, even these high-tech marvels face a subtle challenge: magnetic leakage.

Left unchecked, it can quietly sap efficiency and accuracy. That’s why the newest generation of vacuum linear motors with low magnetic leakage is transforming industries from cutting-edge semiconductor fabrication to next-level robotics, ensuring performance that’s as clean and precise as the vacuum they operate in.

What Are Vacuum Linear Motors?

Vacuum linear motors are specialized electric motors designed to provide precise linear motion without the mechanical contact and friction found in traditional motor systems. Unlike conventional rotary motors, which convert electrical energy into rotational motion, vacuum linear motors directly generate motion along a straight path. This direct-drive mechanism allows for extremely smooth and accurate movement, making them ideal for high-precision applications where even the slightest deviation can affect outcomes.

At the heart of a vacuum linear motor is the interaction between a magnetic field and a conductive moving part, usually called the forcer or rotor. The stator generates a controlled magnetic field, and the forcer moves along it in a straight line. Because the motor operates in a vacuum environment, it eliminates air resistance, reduces thermal effects, and minimizes contamination, factors that are critical in fields such as semiconductor manufacturing, laboratory automation, and medical equipment production.

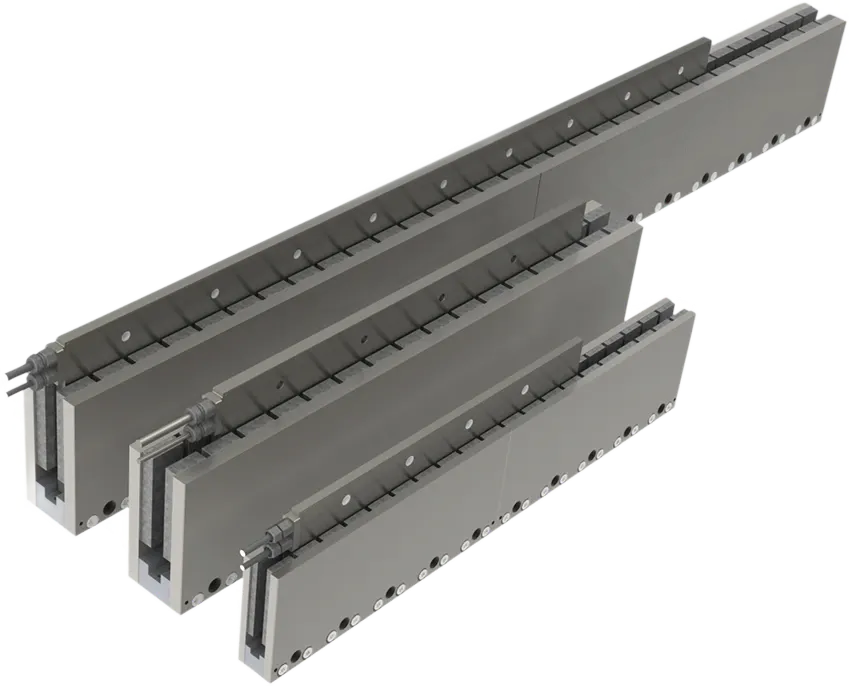

Key Components of Vacuum Linear Motors

To fully understand how vacuum linear motors achieve their exceptional precision and performance, it is essential to examine their key components. Each element plays a critical role in ensuring smooth linear motion, minimal magnetic leakage, and high reliability in vacuum environments.

1. Stator

The stator is the stationary part of the motor and the primary source of the magnetic field that drives motion. In vacuum linear motors:

- The stator contains precisely wound coils that generate a uniform magnetic field along the linear path.

- Advanced designs focus on reducing stray magnetic flux, which is essential for low magnetic leakage performance.

- High-quality materials with low magnetic permeability are used to contain the field efficiently and reduce energy loss.

The design of the stator directly impacts the motor’s efficiency, smoothness of motion, and overall precision. A well-engineered stator ensures that the motor can deliver consistent force and maintain exact positioning over repeated cycles.

2. Forcer (Rotor)

The forcer, often called the rotor in traditional terminology, is the moving part of the motor that reacts to the magnetic field generated by the stator. Key aspects include:

- Linear motion conversion: The forcer moves along the stator without mechanical contact, providing frictionless, smooth travel.

- High responsiveness: The mass and magnetic design allow rapid acceleration and deceleration, which is vital in high-speed industrial or research applications.

- Precision engineering: The interaction between stator and forcer ensures highly repeatable positioning, often at the sub-micron level.

In essence, the forcer translates the magnetic energy into highly controlled linear motion, making it the heart of the vacuum linear motor’s performance.

3. Position Sensors

Position sensors are crucial for monitoring the forcer’s location in real time, enabling feedback control systems to achieve exact movement. They:

- Provide precise measurement of travel distance and velocity, often at nanometer resolution.

- Allow closed-loop control systems to correct deviations instantly, ensuring high repeatability.

- Protect the system by detecting unexpected movements or misalignment, which is critical in sensitive applications like semiconductor manufacturing or laboratory automation.

Without accurate position sensors, even the best motor design cannot maintain the precision needed in advanced applications.

4. Guide Systems

Although the motor is direct-drive, guide systems provide mechanical support to maintain alignment and stability:

- Linear guides or rails: Ensure the forcer travels along a straight path without wobble or tilt.

- Reduced friction: Even in vacuum, guides minimize resistance and prevent unwanted vibration.

- Load handling: Support the payload while maintaining precision, critical for heavy or delicate components.

The guide system works in tandem with the motor’s magnetic design to ensure smooth, stable, and precise linear motion throughout the entire operational range.

5. Housing and Magnetic Shielding

The housing of vacuum linear motors is designed not only to protect internal components but also to manage magnetic leakage:

- Vacuum-compatible materials: Prevent outgassing and maintain a contaminant-free environment.

- Magnetic shielding: Direct stray magnetic fields away from sensitive equipment, enhancing low magnetic leakage performance.

- Thermal management: Prevents heat accumulation, which can affect precision and motor lifespan.

A well-designed housing ensures that the motor operates efficiently, safely, and with maximum precision, even in the most demanding applications.

Vacuum Linear Motors with Low Magnetic Leakage

One of the main challenges in high-precision linear motion is magnetic leakage, where unwanted stray magnetic fields escape from the motor. Magnetic leakage can reduce efficiency, interfere with sensitive equipment, and compromise positional accuracy. To overcome this, engineers have developed vacuum linear motors with low magnetic leakage, offering a significant improvement over conventional designs.

How Low Magnetic Leakage is Achieved

Reducing magnetic leakage requires advanced motor design and precise engineering:

- Optimized Magnetic Circuits: Careful arrangement of magnets and coils ensures the magnetic field is tightly contained within the motor’s core.

- High-Quality Materials: Using low-permeability materials for the motor housing and magnetic shielding reduces stray fields.

- Enhanced Stator and Rotor Design: Innovations in geometry and spacing minimize leakage paths, concentrating the magnetic energy where it is needed.

Key Benefits

1. Improved Accuracy: With minimal interference from stray magnetic fields, vacuum linear motors achieve higher positional precision and repeatability.

2. Energy Efficiency: Low leakage reduces energy loss, allowing motors to operate more efficiently, which is crucial in continuous or high-speed applications.

3. Reduced Equipment Interference: Sensitive instruments and electronics nearby remain unaffected, which is especially important in semiconductor fabs, research labs, and medical environments.

4. Longer Lifespan: Reducing unwanted magnetic stress and heat accumulation extends the operational life of both the motor and surrounding equipment.

Real-World Applications of Vacuum Linear Motors

Vacuum linear motors with low magnetic leakage are transforming industries that demand unparalleled precision, speed, and reliability. Unlike conventional motors, these advanced systems provide direct linear motion in a vacuum environment, eliminating friction, reducing contamination, and ensuring highly repeatable performance. Let’s explore in detail how they are applied in the real world.

1. Semiconductor and Electronics Manufacturing

Semiconductor production is one of the most demanding industries when it comes to precision. Even microscopic deviations can render entire wafers or microchips defective. Vacuum linear motors are widely used in:

- Lithography systems: Ensuring the mask and wafer alignment with nanometer precision, which is impossible with traditional mechanical actuators.

- Wafer handling robots: Smooth, frictionless motion prevents particle generation, which is critical in cleanroom environments.

- Assembly of microelectronic components: High-speed, precise linear motion allows automated assembly of complex microchips with minimal error rates.

The low magnetic leakage feature is crucial here because it prevents stray magnetic fields from interfering with highly sensitive sensors and measurement devices, maintaining the integrity and accuracy of the entire manufacturing line.

2. Scientific Research and Laboratory Automation

Modern research facilities demand motion systems that can operate with extreme stability and minimal interference. Vacuum linear motors are applied in:

- Particle accelerators: Accurate positioning of beamline components is vital; magnetic leakage could distort particle paths.

- Electron microscopy: Nanometer-level sample positioning requires motors that provide smooth and exact linear motion.

- Automated lab equipment: Liquid handling robots and analytical instruments rely on precise, repeatable motion to ensure consistent experiment results.

By eliminating mechanical contact and operating in a vacuum, these motors reduce vibration and thermal drift, allowing experiments and measurements to be far more reliable than with conventional motion systems.

3. Medical Technology

Medical devices often operate near highly sensitive electronics or imaging systems. Stray magnetic fields from standard motors can cause interference, affecting patient safety and diagnostic accuracy. Vacuum linear motors with low magnetic leakage excel in:

- MRI-compatible robotics: Precise linear motion without disrupting magnetic resonance imaging.

- Surgical automation systems: Smooth, controlled motion for minimally invasive procedures.

- Diagnostic equipment: Automated sample handling in lab instruments where contamination and interference must be minimized.

The precise, interference-free operation ensures patient safety, protects expensive equipment, and allows healthcare professionals to perform high-precision tasks reliably.

4. Precision Robotics and Industrial Automation

Industrial automation often requires both speed and precision in confined, electronically dense environments. Vacuum linear motors provide:

- High-speed pick-and-place robots: Rapid, repeatable movement that reduces cycle times.

- CNC machines: Direct-drive linear motion enables micron-level cutting and shaping.

- Assembly lines for sensitive electronics: Smooth, vibration-free movement prevents defects and improves throughput.

Low magnetic leakage ensures that nearby electronics and sensors are unaffected, maintaining overall system reliability. The combination of speed, precision, and stability makes these motors indispensable in modern manufacturing.

5. Advanced Manufacturing

Industries that work at micro- or nano-scale, such as aerospace, optics, and nanotechnology, require precision beyond what traditional motors can deliver. Vacuum linear motors are ideal for:

- Optical lens positioning: Ensuring perfect alignment for high-performance lenses and optical systems.

- Micro-component assembly: Placing tiny parts accurately in automated assembly processes.

- Nanotechnology research: Providing smooth, vibration-free motion for ultra-fine measurements and experiments.

The elimination of friction, the low magnetic leakage, and the ability to operate in vacuum environments make these motors critical tools in cutting-edge manufacturing, enabling innovations that were previously impossible.

How to Choose the Right Vacuum Linear Motor?

Selecting the appropriate vacuum linear motor is crucial for ensuring optimal performance, reliability, and efficiency in high-precision applications. When evaluating options, consider the following key factors:

1. Vacuum Compatibility

Ensure the motor is designed to operate effectively in the specific vacuum environment required for your application. ITG’s Ironless Vacuum Linear Motors are engineered for ultra-clean, high-vacuum environments, achieving outstanding performance even at pressures as low as 10⁻⁸ mbar .

2. Force and Speed Requirements

Assess the force and speed specifications needed for your application. For instance, ITG’s ILV91 Series offers continuous thrust capabilities and high-speed performance, catering to demanding applications in semiconductor, display, and scientific equipment .

3. Outgassing and Particle Emission

Low outgassing and minimal particle emission are essential to maintain the integrity of sensitive environments. ITG’s ironless design minimizes these factors, making their motors suitable for cleanrooms and other sensitive settings .

4. Thermal Management

Effective thermal management ensures consistent motor performance and longevity. Consider motors with designs that facilitate efficient heat dissipation to prevent overheating and maintain optimal operation.

5. Integration and Compatibility

Evaluate the ease of integration with existing systems and compatibility with control electronics. ITG’s motors are designed for seamless integration, ensuring smooth operation within various setups.

By carefully considering these factors and aligning them with your specific application needs, you can select a vacuum linear motor that delivers precise, reliable, and efficient performance. ITG’s Ironless Vacuum Linear Motors offer a compelling option for industries requiring high-precision motion in ultra-clean environments.

Conclusion

Vacuum linear motors with low magnetic leakage are redefining what’s possible, enabling breakthroughs in semiconductor manufacturing, scientific research, medical technology, and precision automation. By minimizing magnetic interference, reducing contamination, and delivering frictionless linear motion, these motors ensure that every micron and millisecond counts.

Choosing the right motor considering factors like vacuum compatibility, force, speed, and thermal management is key to unlocking the full potential of your systems. Advanced solutions, such as ITG’s Ironless Vacuum Linear Motors, demonstrate how thoughtful engineering can elevate performance while maintaining the strictest precision standards.

For engineers, researchers, and innovators alike, mastering the selection and application of vacuum linear motors is not just a technical decision, it’s a step toward achieving the highest levels of efficiency, accuracy, and reliability in today’s most demanding environments.