AC electric motors are everywhere from the fans in our homes to the powerful machinery in industrial plants. But have you ever wondered how they actually work, or why they’re often chosen over DC motors? As industries continue to automate and optimize, understanding the fundamentals of AC electric motors has never been more relevant. In this article, we’ll break down what an AC motor is, how it operates, how it compares to its DC counterpart, and why it remains a cornerstone of modern mechanical systems.

What Is an AC Electric Motor?

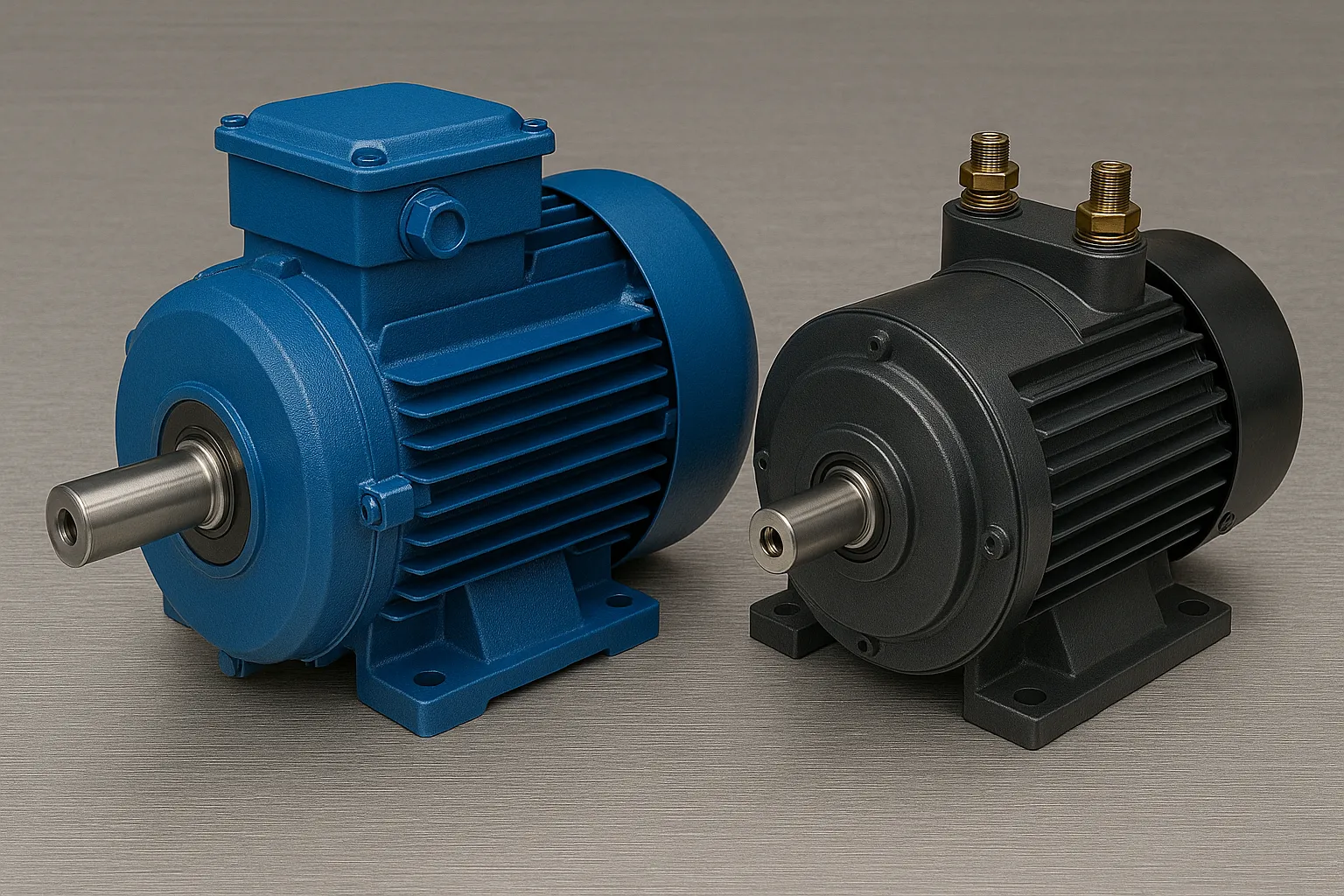

An AC electric motor is a type of electric motor that uses alternating current (AC) to generate mechanical motion. Unlike DC motors, which rely on direct current, AC electric motors operate by converting electrical energy into rotational energy through the interaction of a magnetic field and a current-carrying conductor.

At the core of every AC motor lies a stator and a rotor. The stator produces a rotating magnetic field when supplied with alternating current. This magnetic field induces a current in the rotor, which in turn creates torque and causes the rotor to spin. This is the fundamental principle behind electric motors AC reliable, consistent, and widely adaptable across industries.

There are two primary categories of AC electric motors: synchronous and induction (asynchronous) motors. Induction motors, particularly small AC electric motors, are the most common in commercial and industrial applications due to their simple design, robustness, and efficiency. Synchronous motors, on the other hand, are used when precise speed control is required.

From household appliances to large-scale manufacturing, electric AC motors play a crucial role in modern life. Even in the field of electric vehicles, the debate continues do electric cars use AC or DC motors? While both types are used, many modern electric cars rely on high-performance AC linear electric motors or three-phase AC motors due to their high torque and regenerative braking capabilities.

In short, ac electric motors offer an efficient, cost-effective, and scalable solution for a wide range of mechanical applications making them indispensable in today’s world of automation and innovation.

Main Components of an AC Motor

To understand how AC electric motors function, it’s essential to look at their core components. While there are different types of AC motors, including small AC electric motors used in appliances and large industrial machines, most share a similar internal structure. Here are the primary elements that make these electric motors AC systems work:

1. Stator

The stator is the stationary part of the motor, responsible for generating the rotating magnetic field. It consists of coils of insulated wire arranged around a laminated iron core. When alternating current flows through these windings, it creates a changing magnetic field that drives the rotor.

2. Rotor

Located inside the stator, the rotor is the rotating part of the motor. In most AC electric motors, the rotor is either a squirrel cage type or wound type. The interaction between the stator’s magnetic field and the rotor generates torque, causing it to spin and deliver mechanical power.

3. Bearings

Bearings support the rotor and allow it to rotate smoothly with minimal friction. They are crucial in ensuring long-lasting performance, especially in small AC electric motors where precise movement and reliability are required.

4. Shaft

The shaft is connected to the rotor and transmits the mechanical power generated by the motor to the external load. It’s a critical component that turns rotational energy into usable work.

5. End Bells (or End Covers)

These are mounted at both ends of the motor housing and support the bearings. They also protect internal components from dust, debris, and external damage.

6. Cooling System

Depending on the motor’s size and application, cooling may be passive (through ventilation) or active (using fans or liquid cooling systems). Efficient cooling ensures the longevity and safe operation of electric motors AC in demanding environments.

Together, these components allow AC electric motors to convert electrical energy into smooth, reliable motion, whether it’s in household devices or large-scale industrial machinery.

Types of AC Electric Motors

AC electric motors come in various types, each designed to suit specific performance requirements and operational conditions. The two primary categories are synchronous motors and asynchronous (induction) motors. Within these broad groups, there are specialized variations that serve everything from industrial machinery to compact home appliances.

1. Induction Motors (Asynchronous Motors)

Induction motors are the most widely used type of electric AC motors. They operate on the principle of electromagnetic induction, where the stator’s rotating magnetic field induces current in the rotor without direct electrical connection. These motors are simple, durable, and cost-effective, making them ideal for small AC electric motors used in fans, compressors, and conveyors.

There are two types of induction motors:

- Single-phase induction motors – typically used in domestic appliances and small tools.

- Three-phase induction motors – commonly found in industrial and commercial settings due to their efficiency and power.

2. Synchronous Motors

Unlike induction motors, synchronous motors rotate at a constant speed in sync with the frequency of the AC power supply. These AC electric motors are perfect for applications requiring precise speed control, such as robotics, conveyors, or instrumentation systems. They may use permanent magnets or DC-excited rotors for synchronization.

3. AC Linear Motors

A more advanced type of motor is the AC linear electric motor, which generates motion in a straight line instead of rotation. These motors are used in high-speed trains, advanced automation systems, and precision cutting tools. Their unique ability to provide direct linear motion makes them stand out in industries requiring high-speed, non-rotary movement.

4. Universal Motors

Though technically compatible with both AC and DC power, universal motors are often included in discussions about electric motors AC due to their presence in devices like power tools and household appliances. They offer high-speed operation in a compact design but are less energy-efficient than induction motors.

From small AC electric motors in everyday gadgets to powerful three-phase machines in factories, the range of AC electric motors available today is both diverse and versatile. Choosing the right type depends on factors like load requirements, speed control, and energy efficiency.

Key Differences Between AC and DC Motors

Understanding the fundamental differences between AC and DC motors is crucial for selecting the right motor for your application. While both serve the same core function converting electrical energy into mechanical motion, they differ significantly in construction, operation, and use cases.

1. Power Source and Current Type

The most basic difference lies in the type of electrical current they use. AC electric motors are powered by alternating current, which changes direction periodically. This makes them ideal for environments where grid electricity is available. In contrast, DC motors operate using direct current, which flows in a single direction, typically sourced from batteries or DC power supplies.

This distinction not only affects how the motors are powered but also impacts their efficiency, complexity, and maintenance requirements.

2. Construction and Maintenance

DC motors usually have a more complex mechanical design, including brushes and a commutator that facilitate current flow to the rotor. These components tend to wear over time, requiring more frequent maintenance. On the other hand, most electric AC motors, especially induction types have fewer moving parts, resulting in less wear and longer service life.

This difference makes AC electric motors more suitable for continuous operation in industrial and commercial settings, while DC motors are often favored in applications where compact design and variable speed are prioritized.

3. Control and Speed Regulation

DC motors are generally easier to control in terms of speed and torque, which is why they are widely used in electronics, robotics, and smaller devices. However, modern advancements in AC motor controllers such as variable frequency drives (VFDs) have significantly narrowed this gap, allowing AC electric motors to offer precise speed control in more demanding environments.

In high-performance applications, including automation and manufacturing, AC motors now rival DC motors in flexibility thanks to these innovations.

4. Application Suitability (Including Electric Vehicles)

The debate on whether electric cars use AC or DC motors is a common one. Early electric vehicles relied more heavily on DC motors due to their simpler control systems. However, most modern electric vehicles now use AC electric motors, particularly three-phase AC induction or synchronous motors, because they offer better efficiency, power density, and regenerative braking.

So, are electric car motors AC or DC? The answer today leans heavily toward AC. These motors are more efficient at high speeds and can be powered through onboard inverters that convert DC from the battery into AC.

In summary, the choice between an AC and DC motor depends on your specific needs. If you’re looking for durability, low maintenance, and efficiency in large-scale or continuous applications, ac electric motors are likely the better fit. On the other hand, DC motors may still be ideal for precision tasks or battery-powered systems.

Advantages of AC Electric Motors

AC electric motors have become a staple in both industrial and commercial applications due to their versatility, reliability, and efficiency. Here are the key benefits that make them a top choice for engineers and system designers:

- Low Maintenance Requirements: Most AC motors especially induction types have no brushes or commutators, resulting in fewer parts that wear out over time and less need for regular servicing.

- High Efficiency and Power Density: AC motors, particularly three-phase models, deliver strong performance and energy efficiency, making them suitable for continuous and heavy-duty applications.

- Scalability and Flexibility: From small AC electric motors used in home appliances to large-scale industrial drives, AC motors are available in a wide range of sizes and configurations to meet diverse application needs.

- Cost-Effective Operation: Their simple construction and widespread availability make AC motors relatively affordable, both in terms of initial cost and long-term energy use.

- Compatibility with Modern Control Systems: With the integration of Variable Frequency Drives (VFDs), AC motors now offer precise speed and torque control, once considered a key advantage of DC motors.

Whether you’re building automated machinery, designing HVAC systems, or evaluating electric vehicle powertrains, electric AC motors offer a powerful combination of efficiency, durability, and control. Their ability to scale across applications from small AC electric motors to industrial giants makes them an indispensable component in modern engineering.

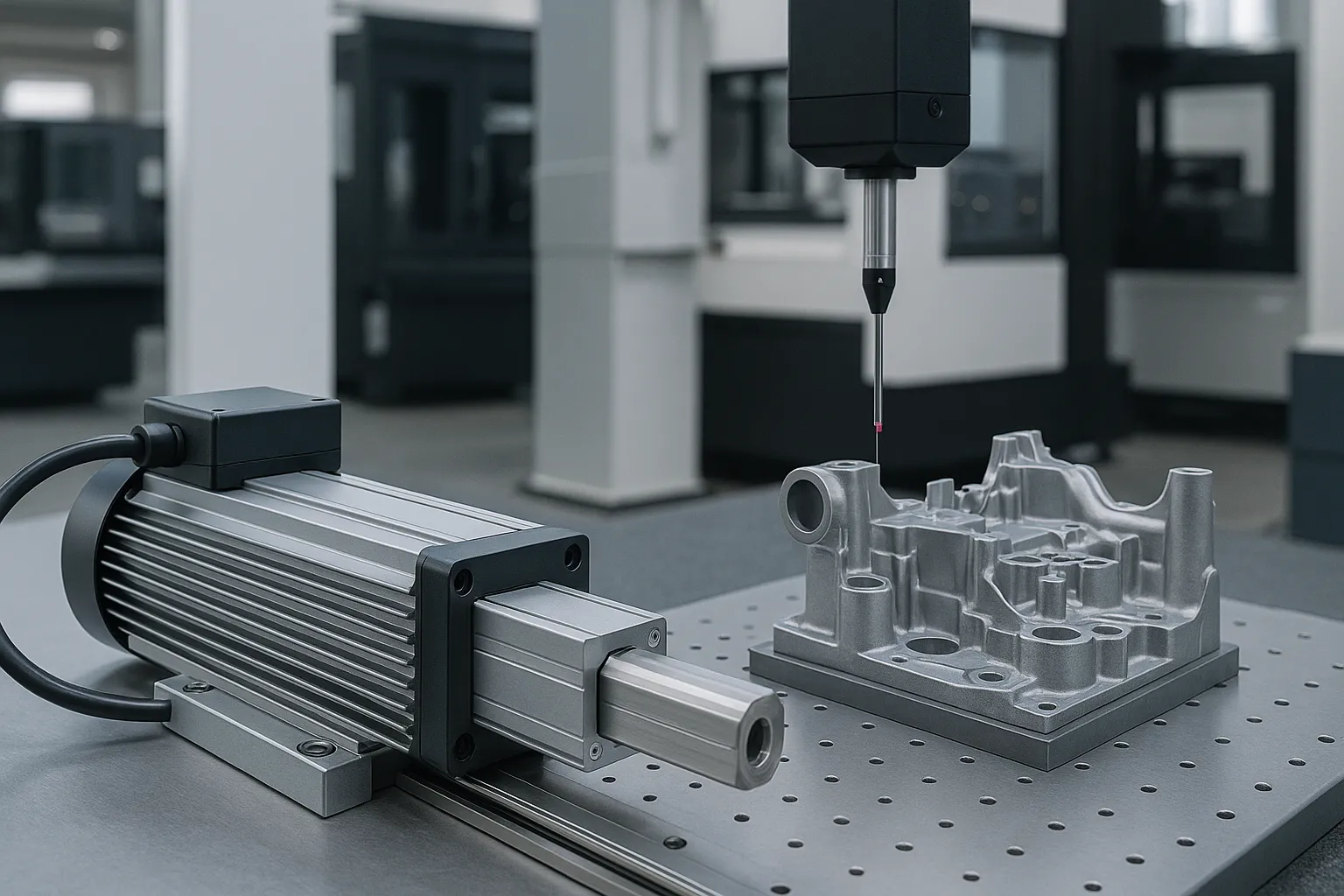

Common Applications of AC Linear Electric Motors

AC linear electric motors are increasingly used in modern industries thanks to their ability to generate direct linear motion without the need for additional mechanical conversion systems. Their unique design and efficiency make them ideal for a wide range of applications across sectors.

1. Industrial Automation and Robotics

In automated manufacturing systems, linear AC motors provide high-speed, high-precision motion essential for tasks like pick-and-place operations, sorting, and material transport. Their compact form and fast response time make them ideal for robotic arms and gantry systems.

2. Transportation Systems

One of the most high-profile applications of AC linear electric motors is in maglev trains (magnetic levitation). These motors enable frictionless, high-speed travel by propelling the train using electromagnetic forces instead of traditional rotary motion and wheels.

3. Semiconductor and Electronics Manufacturing

In cleanroom environments, where precision and cleanliness are paramount, electric AC motors in linear form are used in wafer handling, inspection, and lithography equipment. Their contactless operation reduces vibration and contamination.

4. Medical and Laboratory Equipment

Linear AC motors are used in MRI machines, surgical robots, and lab automation systems for their quiet operation and precise control. Their smooth linear motion helps improve the reliability of delicate procedures and diagnostics.

5. Packaging and Printing Industries

For high-speed printing, cutting, and packaging processes, ac linear electric motors deliver exceptional performance with consistent accuracy. They eliminate mechanical backlash and provide better synchronization compared to traditional belt or pulley systems.

As automation and precision continue to shape the future of engineering, AC linear electric motors are playing a pivotal role in delivering fast, clean, and accurate linear motion. Whether in a high-tech lab or a high-speed train, these motors power the next generation of innovation with unmatched reliability and efficiency.

Conclusion

AC electric motors have become a backbone of modern industry offering efficient, reliable, and scalable solutions for countless mechanical applications. From powering household appliances to driving advanced automation systems and even propelling electric vehicles, their versatility is unmatched.

Understanding how these motors work, how they differ from DC counterparts, and where they excel allows engineers and decision-makers to select the most effective solutions for their needs. As technology advances, the role of electric AC motors especially in sustainable and high-performance systems will only continue to grow.